OMNIedge is for you if...

OMNIedge is for you if...

- Your maintenance process depends on the experience and intuition of expert staff.

- Your maintenance is done on a periodic schedule, regardless of the part’s actual damage or lubrication status.

- You want to start using the IoT, but it's too expensive.

Compatible

components:

- ・LM Guide ・Ball screw

- ・Other machine components

Compatible

equipment:

- ・Machine tools

- ・Injection molding machines

- ・Driving elements under stress

- ・Robot transfer devices

- ・Wrapping machines

- ・Equipment in harsh environments

What Is  ?

?

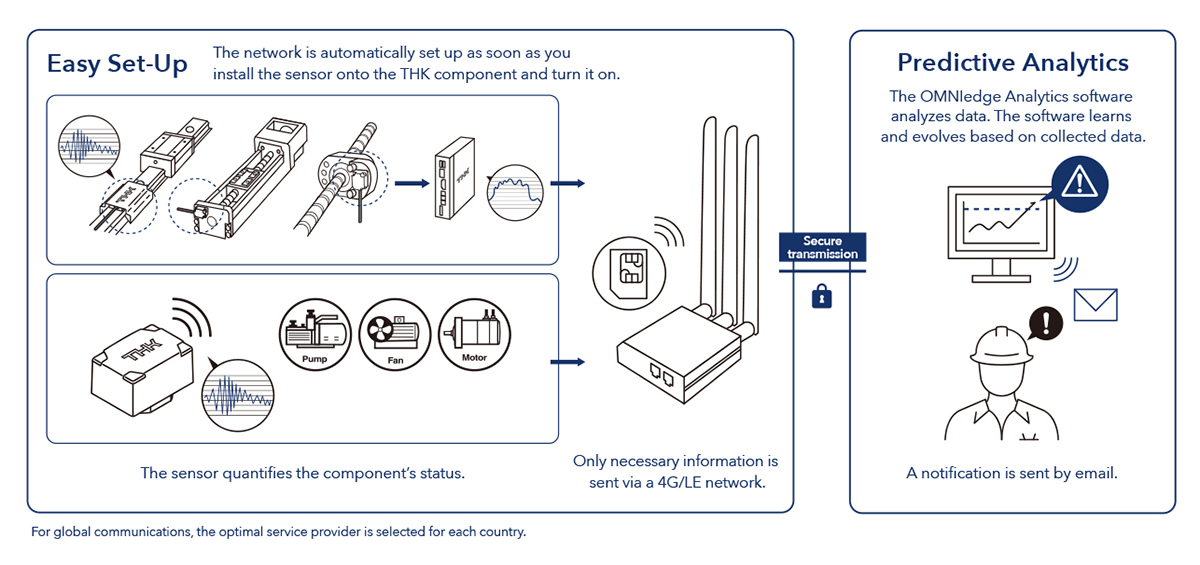

OMNIedge is a system that lets you attach a sensor to a component to quantify and visualize its current condition.

- Collect and analyze component data with the THK SENSING SYSTEM.

-

Easily install on current equipment!

- Receive e-mail notifications about abnormal part conditions.

-

Stay informed about component conditions!

What is the THK SENSING SYSTEM?

This technology uses an original algorithm and extensive reference data to quantify the status of components.

It diagnoses a component’s condition and detects part failure before it occurs.

Make maintenance more efficient, reduce inventory management costs, improve machine operating rates, and support effortless production planning by visualizing the status of components.

System

and Service

We’ve created an IoT package for the manufacturing industry that is simple and safe, with zero initial costs.

The  System

System

Full support before and after implementation!

Full support before and after implementation!

-

- Before

- We listen to the challenges you face and help establish goals and necessary steps for IoT implementation.

-

- After

- We help you expand the service to other production lines and plants around the world.

- A collaboration between leading companies

-

- OMNIedge is a reliable system that combines the strengths of each company involved, including a cloud system, closed network (VPN), and LTE communication system.

Watch an Introduction to OMNIedge

Testimonials

Users report that everyone can now understand the status of the LM Guide, and maintenance is more efficient.

Precision Equipment Manufacturer A

- Before

- Only experienced maintenance employees were able to judge the condition of an LM Guide...

- After

- Now anyone, regardless of experience or location, can understand the damage and lubrication status of an LM Guide by looking at the numbers!

Automotive Component Manufacturer B

- Before

- We were performing maintenance several times a year, regardless of the actual condition of the machine...

- After

- Our efficiency has improved because we can now prioritize maintenance based on the damage and lubrication status of the LM Guide!

Food Manufacturer C

- Before

- Since it would take time to get a new LM Guide after a problem occurred, we kept a large supply on hand, which increased costs...

- After

- We can monitor an LM Guide’s condition and detect signs that maintenance is needed before it breaks. Our inventory stock is now kept at an optimal level!

Price

OMNIedge is offered at easy-to-adopt,

flat-rate subscription pricing.

This system can be implemented with a significantly lower cost than traditional IoT services. Contact us for details.

Based on demand,

OMNIedge will be expanded to visualize conditions of not just the LM Guide,

but ball screws and many other kinds of machine components.

Feel free to consult with us!

+81-3-5730-3932

IOT Innovation Division

OMNIedge Section9:00 a.m.to 5:00 p.m.JST

Excluding weekends and holidays