OEE Optimization System

Condition Monitoring AI Solution

for Linear Motion Components

Visualize linear motion components with an easy-to-install solution

Prevent equipment failure lossAre you experiencing challenges like these?

Maintenance tasks rely on human intuition and experience

Your maintenance process depends on the experience and intuition of expert staff.

TBM

(time-based maintenance)

Maintenance is done periodically, but it feels like you're over-maintaining.

Sudden failure

If a machine fails, there's extended downtime that causes huge losses.

OMNI edge is the solution!

Condition Monitoring AI Solution for Linear Motion ComponentsQuantitatively indicates the lubrication and damage status of linear motion parts !

The AI algorithm calculates abnormality and lubrication scores.

Transform how you perform maintenance

Easy-to-understand component status

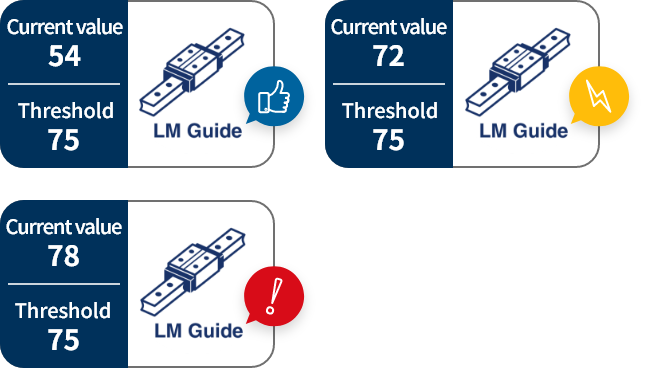

OMNIedge users are aware of the status of components. Should that status exceed normal operating parameters, the OMNIedge system notifies a technician that inspection or maintenance is required.

Quantification and visualization

Efficient

maintenance

The burden of over-maintenance can be reduced by performing maintenance on components with high priority according to their damage and lubrication status.

Improve efficiency of maintenance operations

Reduce losses due to sudden failures

The status of components can be monitored, and signs of failure can be detected before it happens. This prevents machine downtime due to sudden failures, reducing costs and labor time.

Lower costs

Condition Monitoring AI Solution for Linear Motion Components

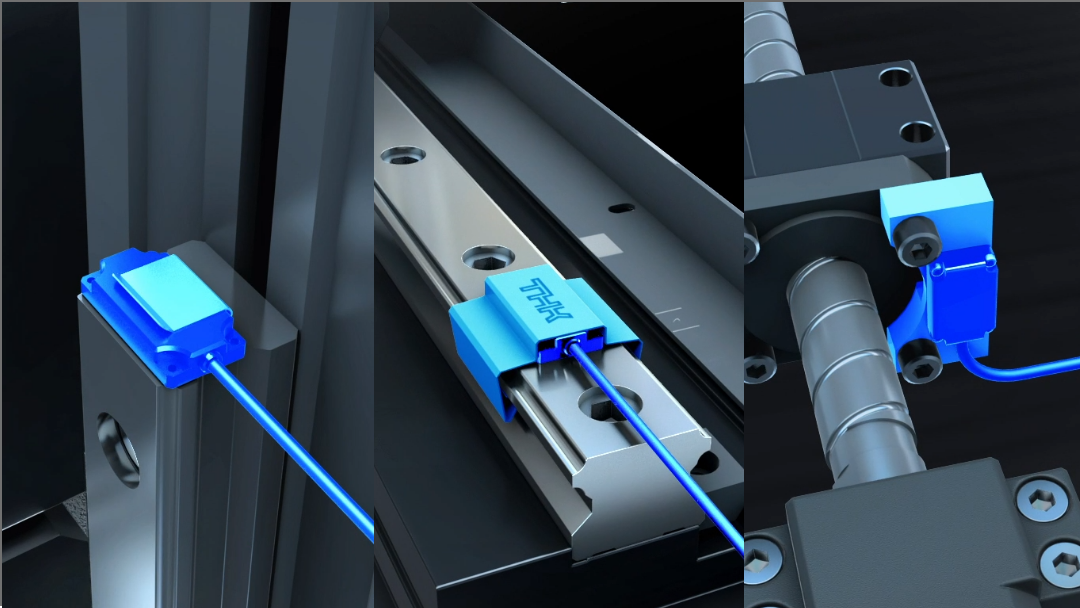

OMNIedge is a system that lets you quantify and visualize a component's condition by simply attaching a sensor to it.

Utilizing an original algorithm and extensive reference data, our component status-quantifying technology (THK SENSING SYSTEM)

collects and analyzes data.

It diagnoses component status and predicts failures, supporting the smooth execution of production plans.

Retrofitting

- Installation possible on both existing machines on the floors and/or new machines

The sensor can be installed on the mechanical components of machines that are already in operation at your facility. It can be installed on any type of machine by using the right fastener.

-

Top surface clamp type

(LM Guide) -

End surface adhesive type

(LM Guide) -

Magnet type

(LM Guide) -

Joint fastening type

(Ball screw) -

Small adhesive surface type

(Actuator) -

Curved-surface adhesive type

(Actuator)

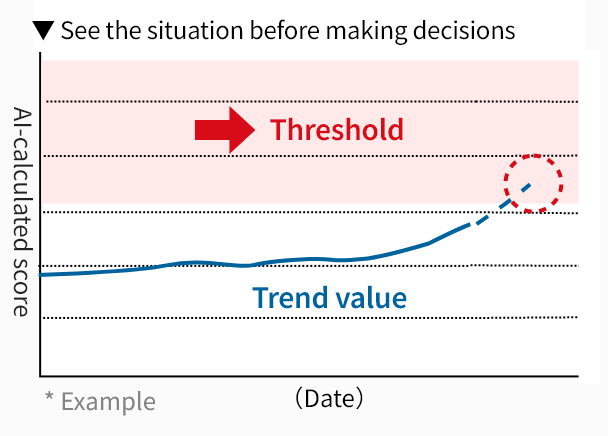

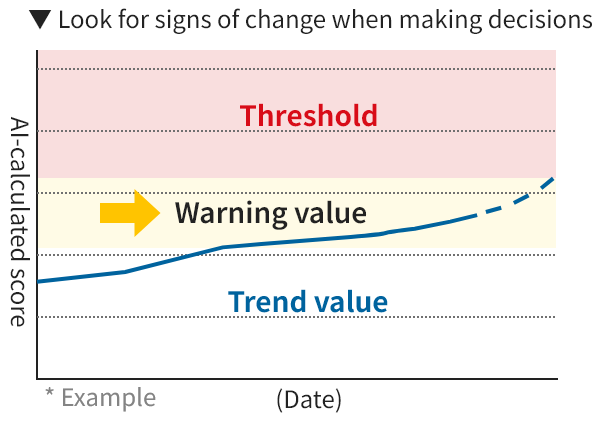

Visualize the Status of Components

- Quantify the lubrication and damage status of linear motion components

- Receive notice of component abnormalities via e-mail

Traditional machine maintenance relies on human interaction and experience, or on a time-based maintenance schedule. OMNIedge quantifies the condition of components providing a more accurate assessment of their operation and removes guess-work and uncertainty from the maintenance process.

AI Diagnostic Service "ADV"

- No threshold setting required

- Automatic change and abnormality notifications

- Linear motion data science experts monitor data and report analysis

Even when using predictive detection, many users are concerned about threshold settings because the status and conditions of each machine are different. That's where the AI diagnostic service "ADV" comes in.

With ADV, there is no need to set thresholds. An AI algorithm calculates the abnormality (damage/lubrication condition) score, and experts analyze the data and provide a monitoring report.

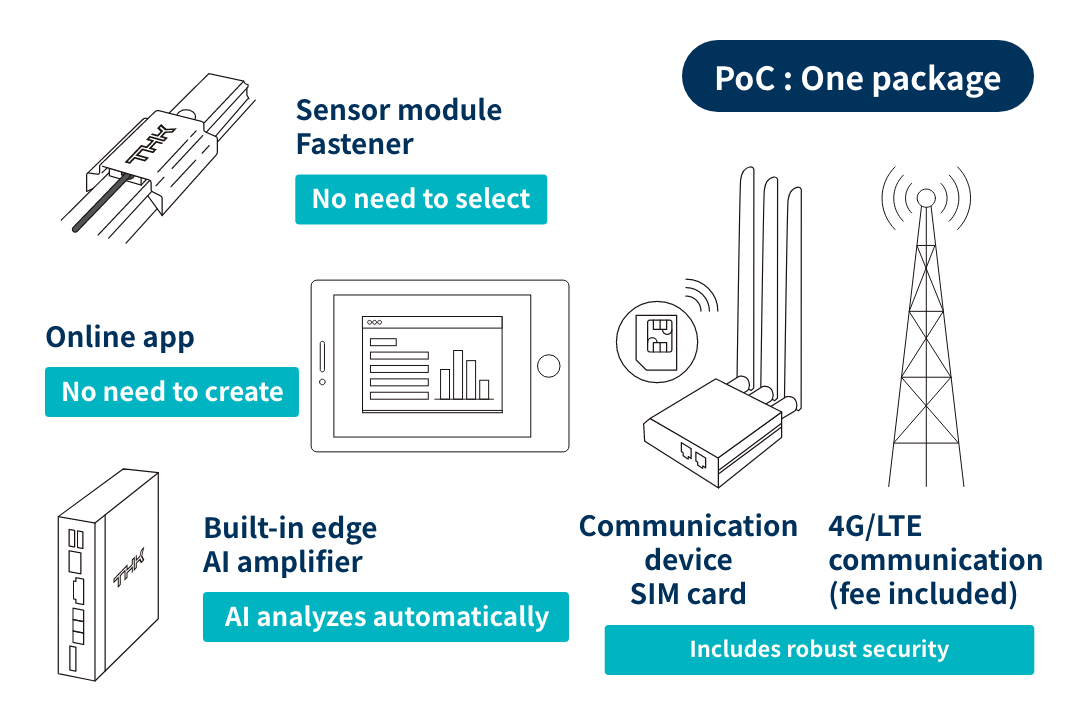

Service Provided for Your Environment from PoC to Full-Scale Implementation

- PoC (Proof of concept)

Everything, including hardware and the communication environment, is provided as a package.

- Full-scale implementation

THK provides suggestions that match your environment when you implement on your lines or throughout your facility.

Solve all your IoT challenges at once

Sensor selection

Which sensor is best?

A special sensor is used, so you don't have to spend time making a selection!

Edge controller selection

Which one should you use?

A special amplifier is used, so you don't have to spend time making a selection!

Data processing

How should you analyze the data?

Edge AI processes the data, so no analysis time is required!

Network construction

Is it difficult to modify the internal network?

The communication environment is included in a package, so the service is ready to use right away.

Secure environment

Do you need to handle data carefully?

The network and cloud provide top-class security.

Final judgment

How should you make judgments?

The cloud AI makes comprehensive judgments! (Currently under development)

Contact THK for a consultation and detailed pricing.

Configuration

OMNI edge is an all-inclusive package from hardware to software. There is no need to build your own infrastructure such as a communication environment.

Easy Setup

The network is automatically set up as soon as you install the sensor onto the linear motion component and turn it on.

The sensor quantifies damage and lubrication status.

Only necessary information is sent via a 4G/LTE network.

The sensor quantifies damage and lubrication status.

Only necessary information is sent via a 4G/LTE network.

transmission

Predictive Analytics

The software analyzes gathered data and uses it to learn and evolve.

Notification by e-mail

- For global communications, the optimal service provider is selected for each country.

Customer feedback during implementation

Electronic component manufacturer

Challenges

The maintenance interval is about three months, and since one or two people are working on 50 machines, it takes a lot of time. The recommended calculation formula is complicated, and I am not sure if the adjustment values are correct.

Deciding factor for implementation

Although the time required for the work itself may not change, the status can be quantified, eliminating the need for complicated data processing. This can lead to improvements in the quality and accuracy of maintenance, such as extending maintenance intervals or changing tooling depending on the equipment condition.

Transportation equipment manufacturer

Challenges

During the welding process, a ball popped out of the block, and the line stopped. The guides are covered, so we often only notice something is wrong after it fails. Also, during the painting process, multiple 3 m guides are connected over a long distance, which makes things very difficult if they break. (Robot travel axis)

Deciding factor for implementation

It would help us out if we could sense these issues with OMNIedge and quantify them.

Automotive component manufacturer

Challenges

For our metal processing machines, machine abnormalities are determined based on criteria set by mechanical machinists. However, with the machine that was replaced this time, even though those criteria found no abnormalities, we did experience issues with the processing quality. Visual inspection revealed that the end plate was damaged.

Deciding factor for implementation

If our maintenance team knows that something is wrong with the equipment, we can take action.

Watch an in-depth video to learn more!

See with an actual machine how easy OMNIedge is to install!

- This in-depth video is limited-access. If you would like to watch it, please submit the required information in the application form.

Support

THK provides support before and after implementation, so you can install the system with peace of mind.

We also provide a monitoring service that checks the acquired data and provides notifications.

Before

- Model selection

- Support and advice regarding the installation location and wiring

After

- Installation support

- Advice for acquired data

AI Diagnostic Service "ADV"

This is a service where THK notifies you of changes.