OEE Optimization System

Condition Monitoring AI Solution

for Rotary Components

Visualize rotary components with an easy-to-install solution

Prevent equipment failure loss

Are you experiencing challenges like these?

Maintenance tasks rely on human intuition and experience

Your maintenance process depends on the experience and intuition of expert staff.

TBM

(time-based maintenance)

There is a heavy burden on maintenance members, and breakdowns between patrols are a concern.

Sudden failure

If a machine fails, there's extended downtime that causes huge losses.

It's difficult to manage predictive failure and abnormality detection.

The volume of rotary components is too vast to monitor them all.

Even if predictive failure detection is implemented, setting all the threshold values is frustrating.

OMNI edge is the solution!

Condition Monitoring AI Solution for Rotary Components Quantify rotary component conditions!

Receive notification of predicted failure modes and before-and-after maintenance reports.

Transform how you perform maintenance.

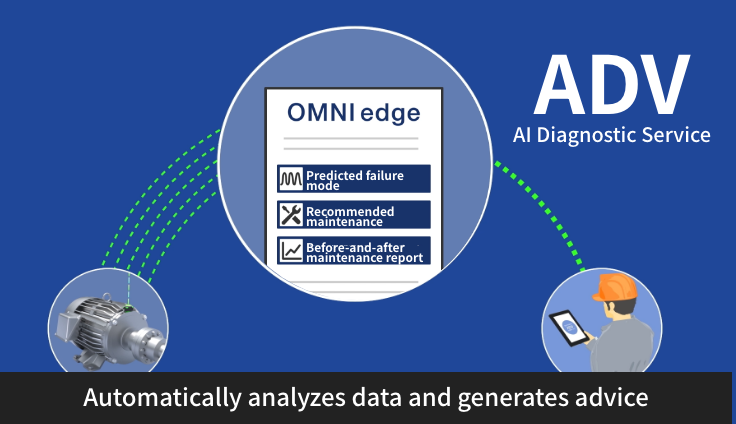

AI communicates the predicted failure mode

The AI accumulates data on rotary equipment, automatically calculates health scores based on installation and drive conditions, and then predicts failure modes.

You don't have to manage various thresholds.

Improve efficiency of maintenance operations

Reduce confirmation time with remote monitoring

Because monitoring can be done with the online app, you can check on the status without having to walk around the facility.The sensors also have LED displays, so you can discern the status at a glance even out on the plant floor.

Less time spent checking

Planned and accurate maintenance

Recommended maintenance details based on the predicted failure mode are provided in addition to before-and-after maintenance reports, enabling planned and accurate maintenance.

Reduce equipment failure loss

Condition Monitoring AI Solution for Rotary Components

OMNIedge is a system that lets you quantify and visualize a component's condition by simply attaching a sensor to it.

Utilizing an original algorithm and extensive reference data, our component status-quantifying technology collects and analyzes data.

It diagnoses component status and predicts failures, supporting the smooth execution of production plans.

Retrofitting

- Installation possible on both existing machines on the floors and/or new machines

The sensor can be installed on the mechanical components of machines that are already in operation at your facility.Additionally, the sensor's LED changes color depending on the status, so you can check the status on-site.

- Communications are conducted wirelessly using Wi-Fi. Please prepare a DC 24 V power cord.

Quantify rotary component conditions

- AI accumulates data about rotary equipment

- No need to manage various thresholds

We also hear from users who have begun data collection, but find utilization challenging.

There are vibrations for each axis (X, Y, and Z), noise, temperature, and so on...

It's hard to determine and manage threshold values for such a large number of items just by intuition.

OMNIedge frees you from the difficulty of setting and managing thresholds for each sensor and item.The AI accumulates data on rotary equipment and calculates an abnormality score based on installation conditions and drive conditions.

Alerts

Predicted failure modes

Recommended maintenance

Diagnostic reports

Alerts

Predicted failure modes

Recommended maintenance

Diagnostic reports

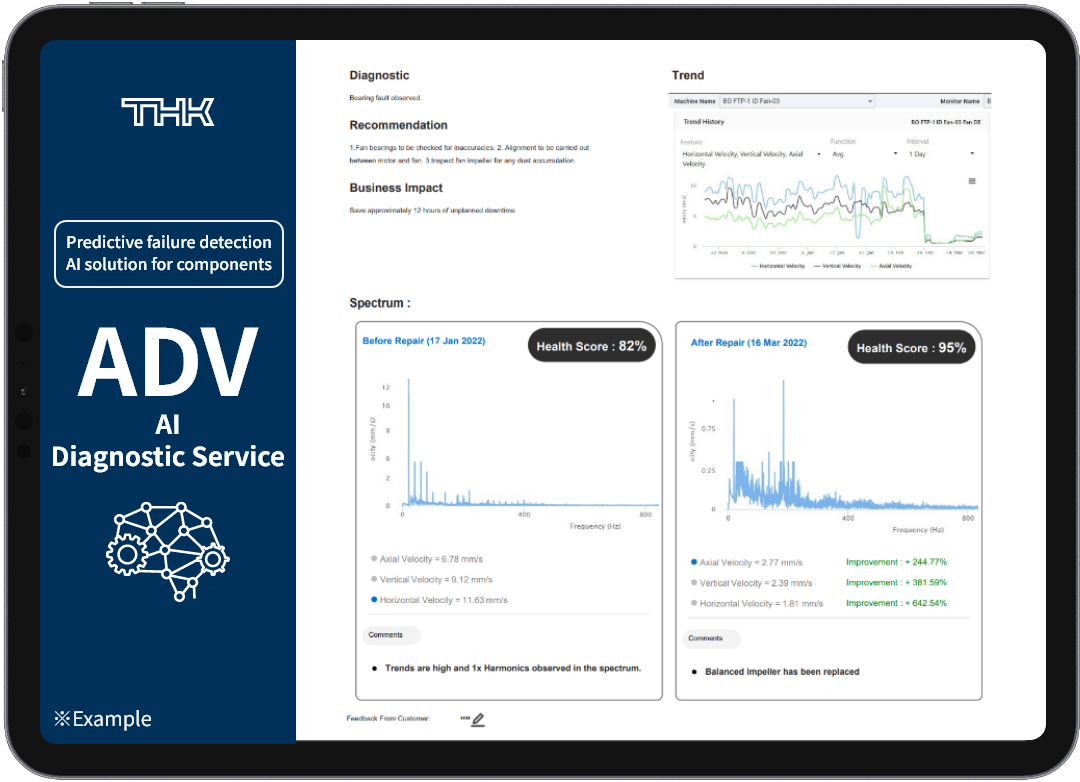

AI Diagnostic Service ADV

- AI communicates the predicted failure mode

- Creates before-and-after maintenance reports

The AI will present the predicted failure mode from the acquired data, and it will also inform you of maintenance details accordingly.

Additionally, after the maintenance is performed, post-maintenance reports are provided that show how your data changed.

1Diagnostic results and recommended maintenance

Explains the diagnosed data and recommended maintenance details

2Changes in trends

Explains changes in trends before and after maintenance

3FFT comparison

Provides notification of frequency analysis results

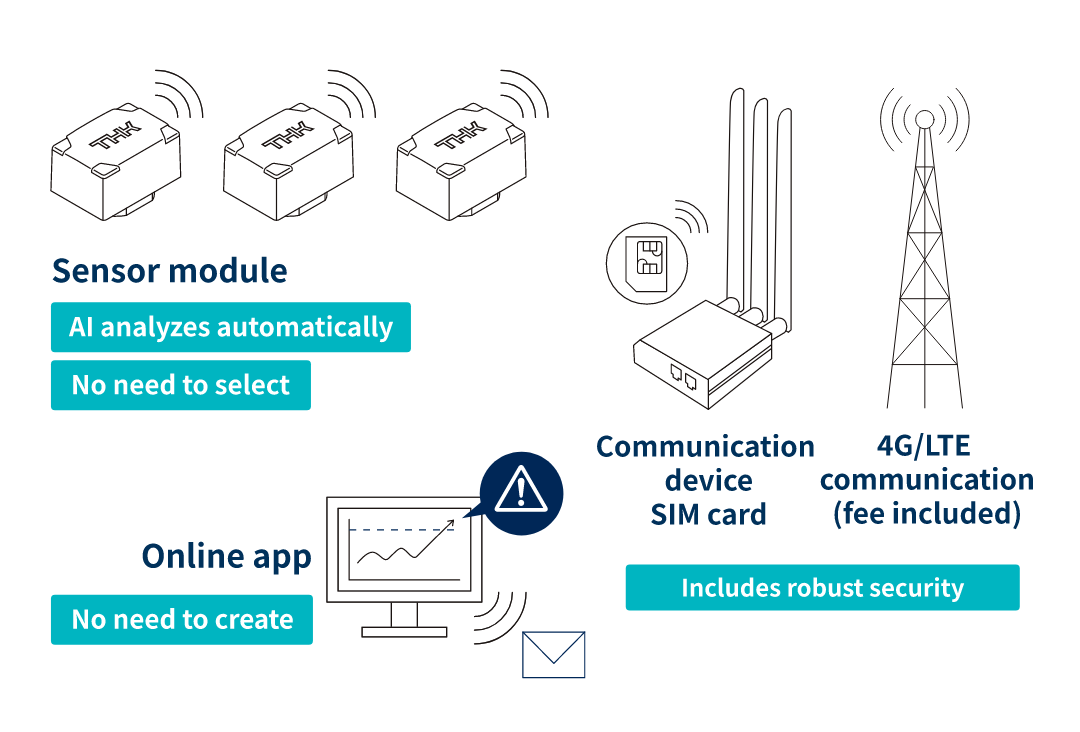

All-in-One Package

- Includes everything from sensors to the communication environment

- No complicated preparation is necessary

THK provides everything from the sensors to the communication environment.

You do not need to take care of any complicated preparations.

Solve all your IoT challenges at once

Sensor selection

Which sensor is best?

A special sensor is used, so you don't have to spend time making a selection!

Edge controller selection

Which one should you use?

A special amplifier is used, so you don't have to spend time making a selection!

Data processing

How should you analyze the data?

Edge AI processes the data, so no analysis time is required!

Network construction

Is it difficult to modify the internal network?

The communication environment is included in a package, so the service is ready to use right away.

Secure environment

Do you need to handle data carefully?

The network and cloud provide top-class security!

Final judgment

How should you make judgments?

The cloud AI makes comprehensive judgments! (Currently under development)

Contact THK for a consultation and detailed pricing.

Configuration

OMNI edge is an all-inclusive package from hardware to software. There is no need to build your own infrastructure such as a communication environment.

Easy Setup

The AI built into the sensor quantifies the status of rotary components.

Up to 12 sensors can connect to one router.

transmission

Secure Operation

Securely collect data via a closed network.

Wi-Fi/router

transmission

Predictive Analytics

The predictive failure detection software analyzes data.The software learns and evolves based on collected data.

Monitoring PC

- For global communications, the optimal service provider is selected for each country.

Support

THK provides support before and after implementation, so you can install the system with peace of mind.

We estimate the predicted failure mode from the acquired data and report a comparison before and after maintenance with the AI Diagnostic Service ADV.

Before

- Model selection

- Radio wave survey

- Site inspection

After

- Installation support

- Advice for acquired data

AI Diagnostic Service "ADV"

This service uses AI to automatically analyze data and create specific and easy-to-understand advice.