OEE Optimization System

Condition Monitoring AI Solution

for Cutting Tools

Reduce tool replacement loss, defects, and rework loss

with AI that evolves

Are you experiencing challenges like these with cutting tools?

Broken and chipped tools lead to defects

Broken and chipped tools lead to defects and rework.

Tool costs are piling up

Managing tool life by piece count is expensive.

OMNI edge is the solution!

Condition Monitoring AI Solution for Cutting ToolsDetect cutting tool damage and chipping!

You can also monitor the degree of wear!

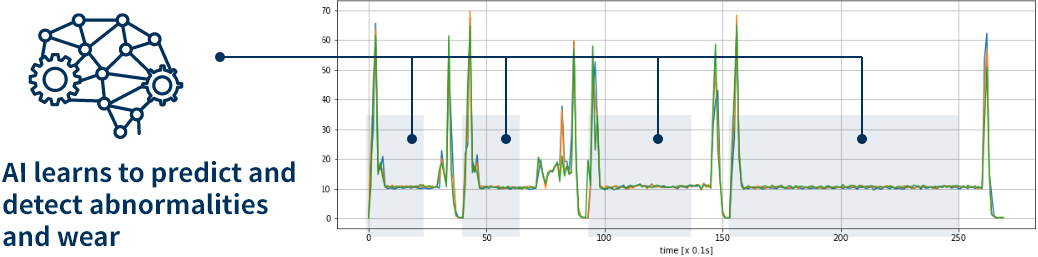

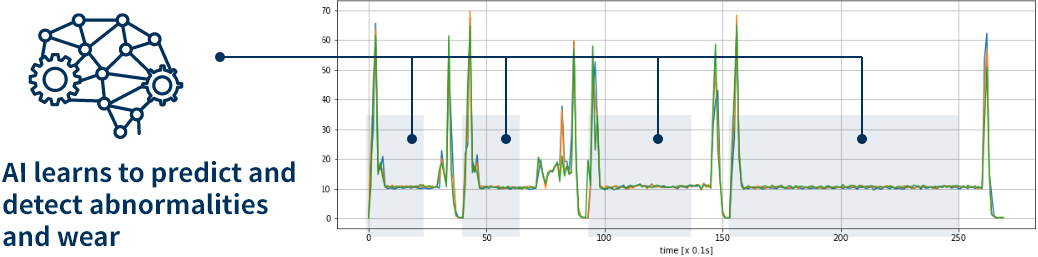

No threshold required! AI detects damage and chipping

During the machining cycle when damage or chipping occurs, the cutting load increases or decreases rapidly. Abnormalities are detected and a notification is sent based on differences in the feature values of the in-process waveform shape.

Optimize the number of tool changes by quantifying the degree of wear

The ability to detect minute abnormalities that can't be caught with break detection makes it possible to set the optimal lifespan for each tool by making adjustments based on product quality.

Prevent Machining Defects

Reduce tool costs by optimizing tool change settings

Prevent machining defects

The system detects tool problems in real time, allowing you to promptly take appropriate action and prevent machining defects.

Reduction of rework loss

Diagnose in real time during processing

Real-time abnormality detection during machining reduces the time required for tool diagnosis (break detection) for each process, contributing to improved productivity.

Cycle time reduction

Reduce frequency of tool changes

By using this system to optimize tool life, you can reduce the frequency of tool changes and save on tooling costs.

Lower costs

Condition Monitoring AI Solutionfor Cutting Tools

Extract cycle data from the current sensor installed on the motor and perform abnormality detection using the learned model.

AI learns the machining waveform for each tool every time it's used, making it possible to detect damage and chipping and to monitor the degree of wear.

There is no need to set thresholds for detecting damage or chipping.

Retrofitting

- Easily retrofit existing equipment with sensors

All you have to do is clamp a CT (current sensor) onto the motor cable, which makes installation easy.No CNC connection is required.

The machining status can be diagnosed using only the information from the retrofitted sensors.There are no restrictions on machine manufacturer, model year, or type of CNC equipment.

No Complicated Settings Required

- No parameter or threshold setting required

The settings tool doesn't require any complicated configuration.The system can immediately start collecting data from the day you install it.

All you need to do is register the processed product, process name, and tool! There is no need to set thresholds or parameters.

Abnormalities are detected without setting a threshold by automatically measuring and learning the current value applied to the tool during cutting.

The system makes judgments based on multiple axes, not just one axis.

Analyze with Evolving AI

- AI diagnoses and detects abnormalities

- AI learns and improves its accuracy

The AI automatically analyzes data to detect abnormal conditions, with no threshold values required.

It learns waveform information during normal operation, and diagnoses anything out of the ordinary.

It also learns over time and improves its accuracy.

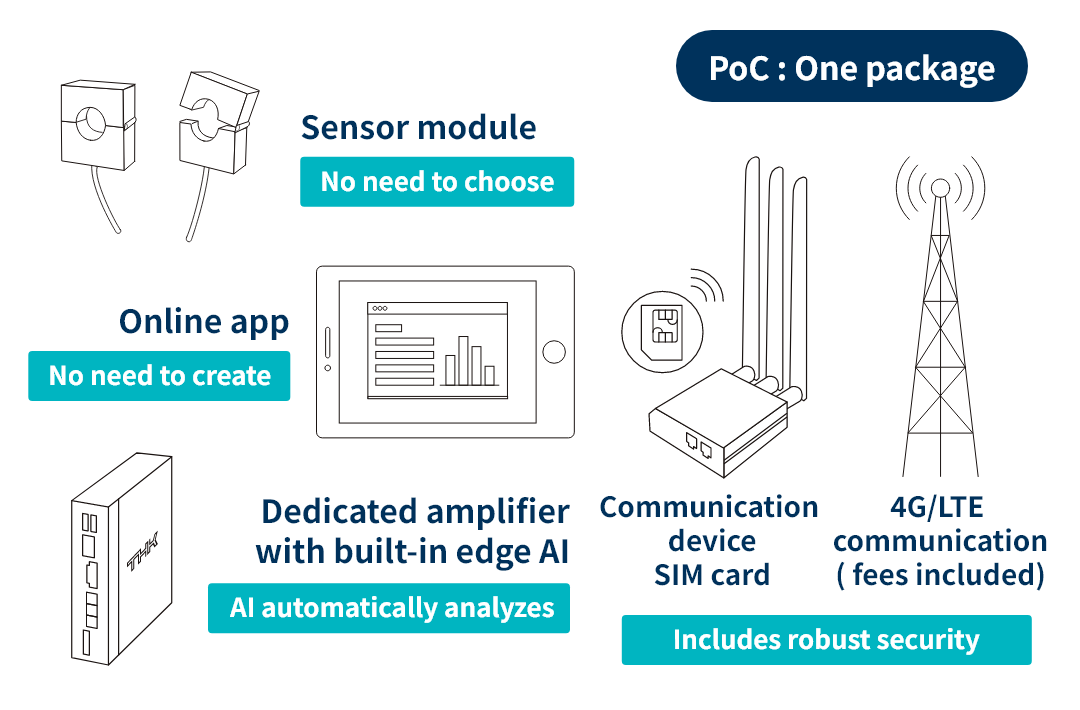

Service Provided for Your Environment from PoC to Full-Scale Implementation

- PoC (Proof of concept)

Everything, including hardware and the communication environment, is provided as a package.

- Full-scale implementation

THK provides suggestions that match your environment when you implement on your lines or throughout your facility.

Solve all your IoT challenges at once

Sensor selection

Which sensor is best?

A special sensor is used, so you don't have to spend time making a selection!

Edge controller selection

Which one should you use?

A special amplifier is used, so you don't have to spend time making a selection!

Data processing

How should you analyze the data?

Edge AI processes the data, so no analysis time is required!

Network construction

Is it difficult to modify the internal network?

The communication environment is included in a package, so the service is ready to use right away.

Secure environment

Do you need to handle data carefully?

The network and cloud provide top-class security!

Final judgment

How should you make judgments?

The cloud AI makes comprehensive judgments! (Currently under development)

Contact THK for a consultation and detailed pricing.

Configuration

OMNI edge is an all-inclusive package from hardware to software. There is no need to build your own infrastructure such as a communication environment.

Easy Setup

The network is automatically set up as soon as you install the CT on the machine tool and turn it on.

The sensor visualizes the tool's status.

Edge AI extracts the feature values and transmits them over a 4G/LTE network.

The sensor visualizes the tool's status.

Edge AI extracts the feature values and transmits them over a 4G/LTE network.

transmission

Secure Operation

Securely collect data via a closed network.

Global expansion is also supported.

transmission

Tooling Management

AI estimates the amount of damage, chipping, and wear on the tool.

Notification by revolving light.

(Monitoring is also possible with a tablet.)

(Output to NC is also possible.)

- For global communications, the optimal service provider is selected for each country.

- The customer only needs to provide the tablet for inputting the tool change history.

Support

THK provides full support before and after installation, so you can install with peace of mind.

We also provide a monitoring service that checks the acquired data and provides notifications.

Before

- Model selection

- On-site confirmation

- ROI proposal

After

- Installation support

- Advice for acquired data

Peace of Mind Package (optional)

THK provides remote support