Download

Download CatalogDownload 2D&3D-CAD

Features

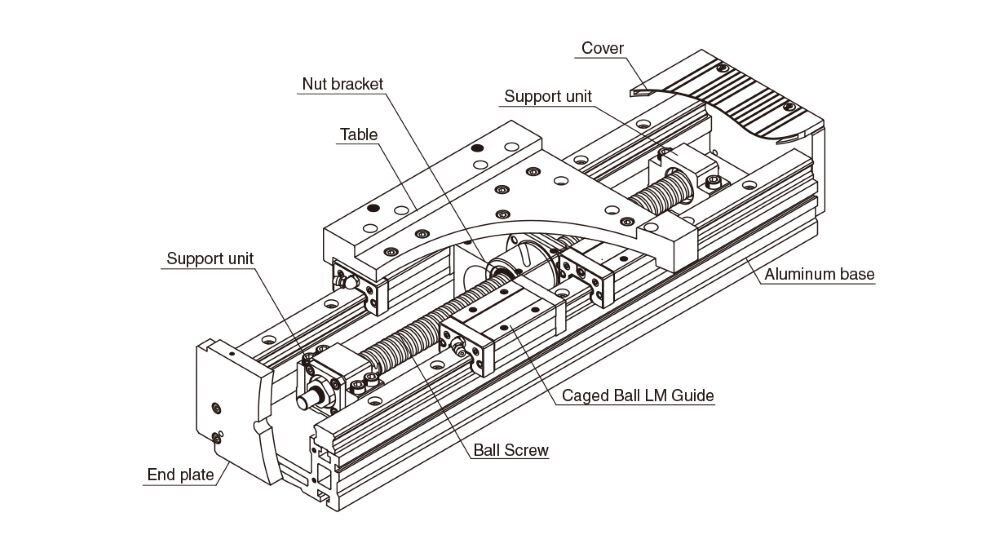

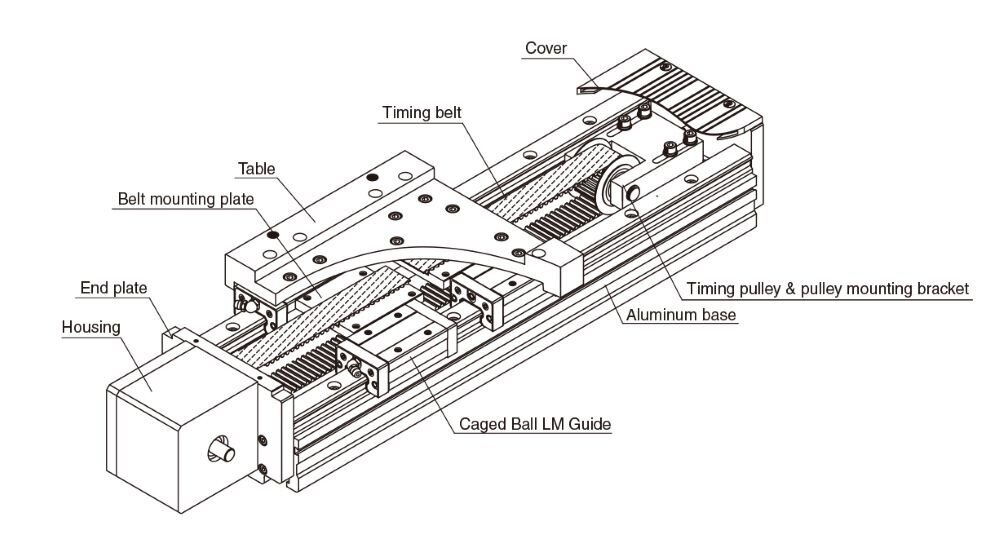

Lightweight, high rigidity aluminum base with Caged Ball LM Guides has

been utilized for the guide portion. A screw or belt options are

available for the drive system.

In addition, Caged Ball LM Guides

and QZ Lubricator for the Ball Screw has been utilized to provide a

long-term maintenance free actuator.

Structure

Ball Screw

Timing Belt

Utilizing Caged Ball LM Guide (SSR, SHS)

-

SSR model:

Due to its 90-degree ball contact structure, is best suited to horizontal applications with relatively low moment loads.

-

SHS model:

It can handle loads from all directions (radial, reverse radial, and horizontal) with its 4-way equal load rating capability.

Drive System

Ball Screw Type

Variety of screw leads can be selected.

| Model number | Ball Screw lead (mm) |

|---|---|

| GL15N | 5, 10, 16, 20, 30 |

| GL20N | 5, 10, 20, 40 |

Note: For wrap-around motor types, three motor directions (left, right and bottom) can be selected. (See page 4 for details.)

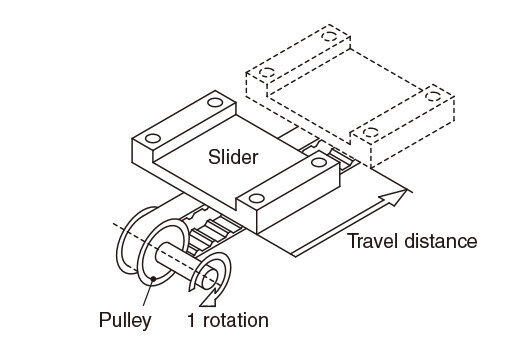

Timing Belt Type

Highly rigid timing belt ensures that high speed processes are possible for longer stroke applications than the Ball Screw driven type.

| Model number |

Pitch diameter (mm) |

Slider move distance per pulley rotation (mm) |

|---|---|---|

| GL15N | 35.01 | 35.01×π≒110 |

| GL20N | 38.20 | 38.20×π≒120 |

Note: Because the timing pulley has a large pitch diameter, the use of a reducer is recommended. For details, see pages 18 and 19.

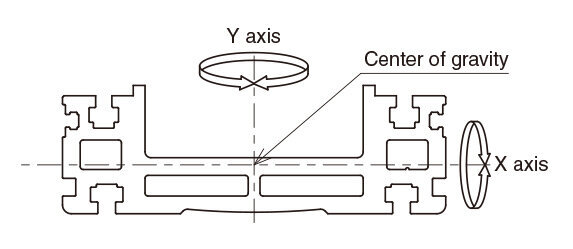

Lightweight and High Rigidity

By using a hollow aluminum extrusion, lightweight and high rigidity is achieved.

| Model number | Geometrical Moment of Inertia | Weight | |

|---|---|---|---|

| lX (mm4) | lY (mm4) | (kg/m) | |

| GL15N | 1.61×105 | 2.47×106 | 4.85 |

| GL20N | 3.15×105 | 4.28×106 | 6.47 * |

* The weight of the SSR model is 6.69kg/m.

GL-N Model also Available with Optional QZ Lubricator

A Caged Ball LM Guide and QZ Lubricator for the Ball Screw have been utilized to ensure a long-term maintenance-free actuator.

Ensuring Adaptability with Most Advanced Motors

A large variety of flanges have been engineered so that a wide selection of motor options are available to be used with the GL-N.

Multiple Options Available

Multiple options such as covers, bellows, sensors and cable carriers are available.

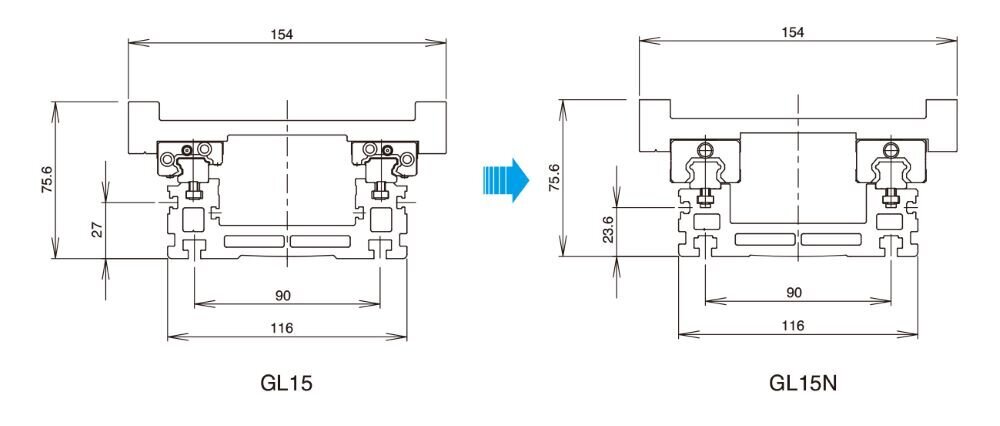

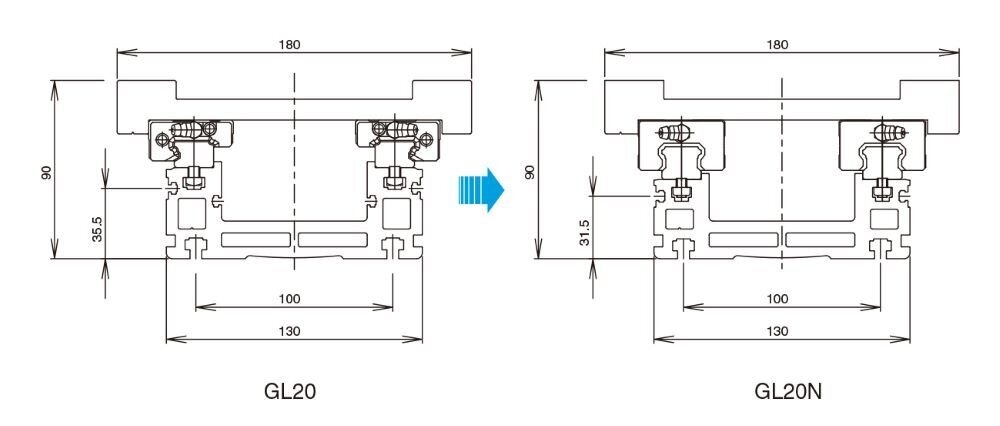

Compatible with the Conventional GL Model

Due to the dimensions between the GL models and the GL-N models are

same.

Replacing with the GL-N is easily possible (GL20N).