Jul 4, 2025

products

Intelligent Condition Monitoring with OMNIedge – For Maximum Equipment Availability

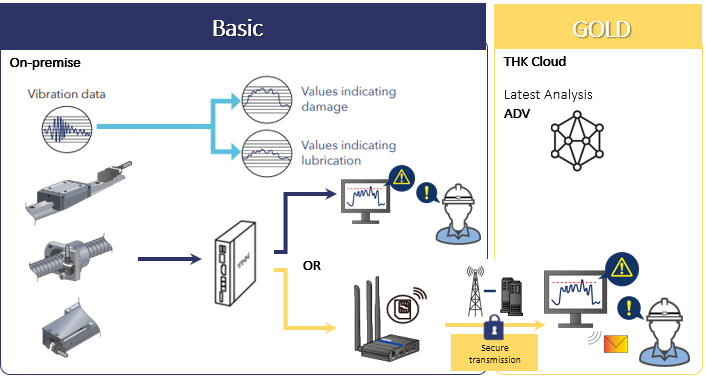

With OMNIedge, THK offers an AI-based system for predictive maintenance of machine components and tool monitoring during continuous operation. The OMNIedge system detects potential faults at an early stage, prevents unplanned downtime, and thus contributes directly to increasing a system’s productivity and improving overall equipment effectiveness (OEE).

Installation requires only the attachment of sensors to relevant components such as linear guides and ball screws – retrofitting existing systems is simple and straightforward. Condition data can then be continuously collected and analyzed using cloud and AI technology to plan appropriate maintenance or lubrication activities.

Another advantage of THK OMNIedge is the optimization of maintenance management: a central system digitally records and manages all maintenance data, enabling more efficient control of PDCA cycles (Plan–Do–Check–Act). Machine condition and maintenance history can be checked anytime, allowing actions to be precisely tailored to actual shopfloor conditions. Additionally, maintenance histories and inspection data are stored in the cloud and can be accessed at any time. Planned maintenance activities can be clearly organized in a calendar, with push notifications ensuring that no inspections are missed.

THK provides a complete GOLD package, which complies with the CE/RD 2014/53/EU Radio Equipment Directive. This package includes sensors and other hardware as well as the necessary web applications for easy visualization and management. This enables companies to implement intelligent condition monitoring with minimal effort. In addition to automated AI data analysis, experienced experts also evaluate the recorded condition data and create precise maintenance reports – both before and after servicing. A basic package without web connectivity is also available.

For more detailed information, please see here:

https://www.thk.com/brand/omniedge/en/Contact information

For more detailed information, please contact THK directly:

THK GmbH

PR Group

+49 2102 7425-151

press@thk.eu

www.thk.com