Jan 14, 2026

products

High-Speed Transfer for Smaller Spaces: Now Accepting Orders for a Small-Head Model Pick and Place Robot with Force Sensor

THK CO., LTD. (Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) is now accepting orders for the PPR2-LR, a small-head model pick and place robot designed for the electronic components industry and ideal for high-speed transfer of minute workpieces.

Our PPR Series of pick and place robots pick up minute workpieces and transfer them to bases or perform assembly operations quickly and accurately. They are capable of basic operations like raising, lowering, and rotating workpieces, and they are equipped with a host of features required for pick and place functions, such as solenoid valves, control modules, and various sensors, including force sensors that measure how much force is applied to a workpiece.

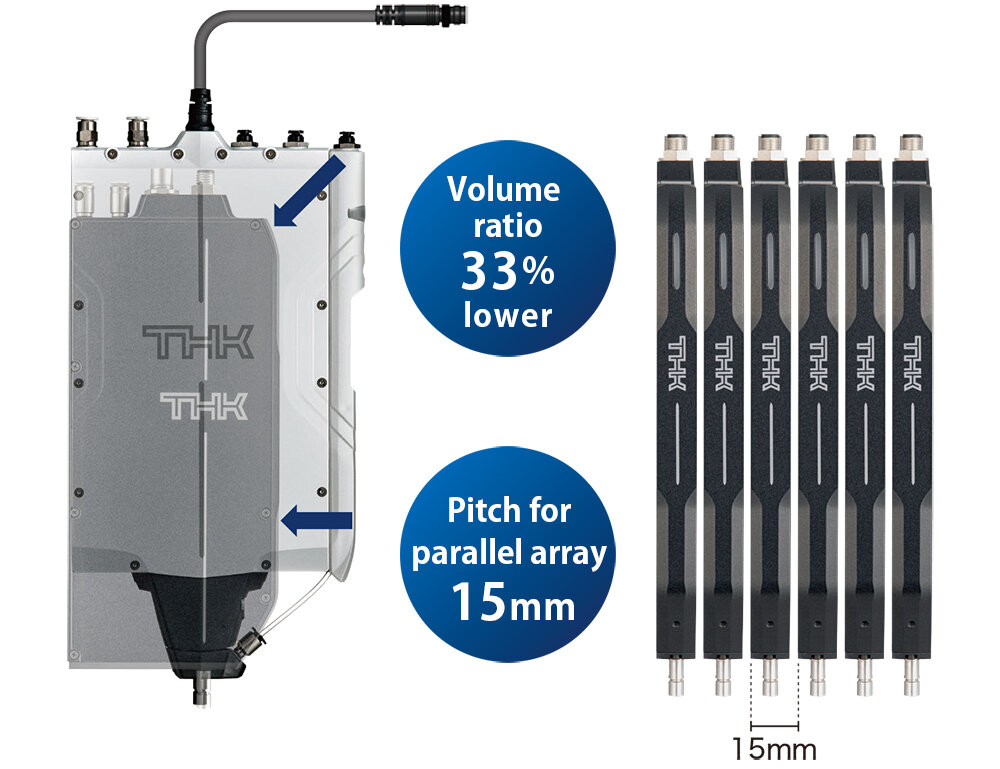

The small-head model PPR2-LR provides a more compact design with a head 33% smaller than our existing integrated pneumatic unit model PPR-LR. This allows it to be installed onto equipment too small to accommodate previous iterations. Its new mechanism keeps runout accuracy at the tip of the shaft within 5 µm to provide even greater accuracy as well.

Recent years have seen skyrocketing demand for smartphones, tablets, wearable devices, integrated car cameras, and other small electronic devices, which has driven advances in device multifunctionality and compactness. Smaller components are easier to break during transfer, though, and increasing the accuracy of contact detection to avoid this often comes at the cost of slower transfer speeds.

The PPR series makes use of THK's unique force-sensing technology to protect workpieces from being damaged as well as an integrated control system that facilitates faster control for reduced cycle times.

Through the development of new, original products, THK will continue to meet the automation and labor-saving needs of all industries, proposing solutions that will boost productivity and improve processes.

Small-head model features

Minimize workpiece damage (minimum detectable force: 0.15 N)

THK's unique force-sensing technology detects contact between the nozzle and workpiece with a high degree of accuracy.

Shorten cycle times (communication cycle: 100 μs)

Integrated sequencer control for motors and sensors. Minimizes lost time with fewer communication cycles than conventional systems.

Highly accurate shaft runout (shaft runout accuracy: 5 μm or less)

Minimizes the size of offsets necessary for alignment adjustments and helps increase accuracy of workpiece placement.

Compact design(33% smaller with a layering pitch width of just 15 mm)

Increases productivity per unit of area with a head that is thinner and more compact than that of the integrated pneumatic unit model.

Related information

Contact information

For more detailed information, please contact THK directly:

THK GmbH

PR Group

+49 2102 7425-151

press@thk.eu

www.thk.com