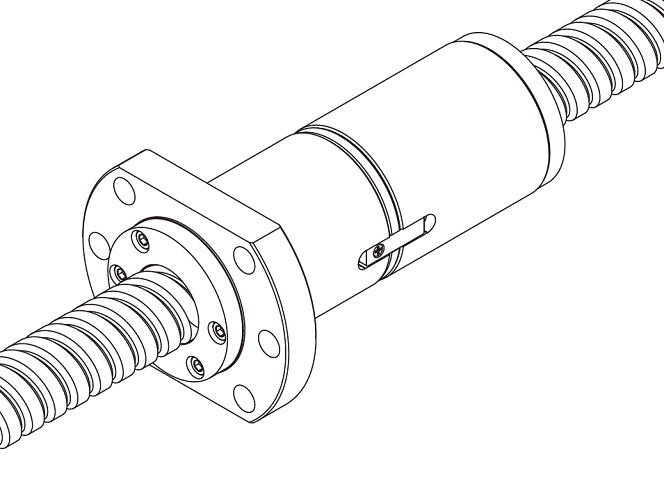

Precision Caged Ball Screw High Speed Model SBKN Model SBKN 36/40/50/55

The preload method utilizes a combination of two ball screw nuts preloaded with spacers to eliminate backlash.

This type has improved load capacity in comparison with the Model SBK.

DN value : 160000

Screwshaftdiameter(mm) :

36,40,50,55

Select display items

Click on the feature tag you wish to view and press the button to display. Detailed information is displayed at the bottom of the screen.

- Select all

- Deselect all

Detailed information

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Optional

Contamination Protection

- Contamination Protection Seal for Ball Screws Labyrinth seal

- Contamination Protection Seal for Ball Screws Brush seal

- Wiper Ring

- Canvas seal

- Thin Film Seal

- Dust Cover for Ball Screws

Lubrication

- QZ Lubricator

Rustprevention

- Surface Treatment

Other

- Dimensions of Each Model with an Option Attached

- Additional Machining for Shaft Ends

Display result

- Detailed information

- Optional

Detailed information

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Optional

No option tag has been selected.

Check detailed information with the tool

Click on the icon for the item you want to see in detail. Member registration and login are required for use.

Designer is the former optimal product selection tool

You can download 2D/3D CAD by clicking on the icon and selecting from the CAD format.