Designing the Housing and the Presser Flange

Since the Cross-Roller Ring is a compact, thin device, special consideration must be given to the rigidity of the housing and the presser flange.

With types having a separable outer ring, insufficiency in the strength of the housing, pressure flange or the presser bolt will result in the inability to evenly hold the inner or outer ring, or the deformation of the Cross-Roller Ring when a moment load is applied. Consequently, the contact area of the rollers will become uneven, causing performance to significantly deteriorate.

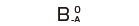

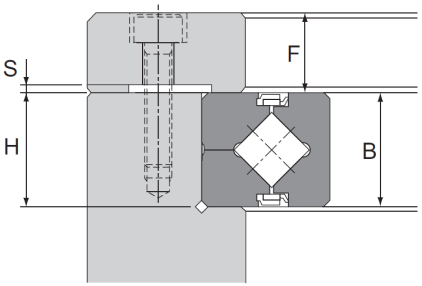

Fig.2 shows examples of installing the Cross-Roller Ring.

Housing

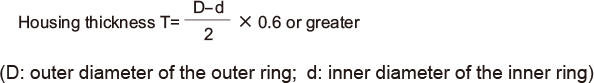

When designing the thickness of the housing, make sure it is at least 60% of the sectional height of the cross roller ring as a general guide.

If greater stiffness is desired, both the thickness of the housing and the fitting tolerance must be considered. Please contact THK when making such considerations.

Shoulder Design

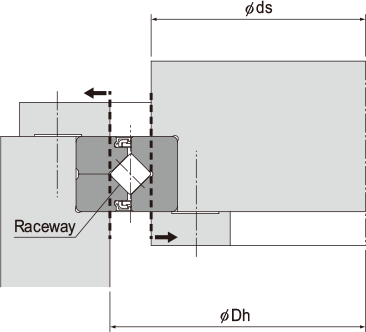

When designing the shoulder, ensure that the shaft shoulder diameter (ø ds) and the housing shoulder diameter (ø Dh) are outside the raceway area.

If the shoulder dimensions are within the raceway area, then an uneven load may apply, resulting in a faulty rotation.

For the shoulder dimensions, see the corresponding specification table.

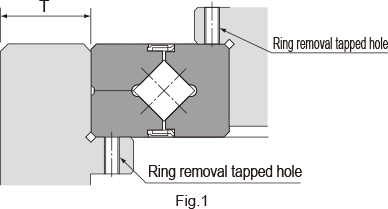

Tapped Hole for Ring Removal

By including tapped holes for inner and outer ring removal ( Fig.1 ), it becomes possible to removethe rings without damaging the cross roller ring.

Avoid pushing the inner ring when removing the outer ring, or vice versa.

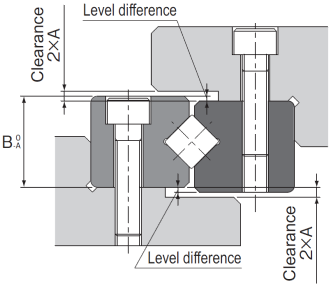

Level difference between the inner and outer rings

Since there is a level difference between the inner and outer rings of the Cross-Roller Ring, it is necessary to provide a clearance in the housing.The clearance must be at least twice the tolerance A of the width dimension.For the tolerance A of the width dimension, see the accuracy standard.

| Model No. | Width dimension |

|---|---|

| RB |

|

| RE | |

| RA,RAU |

|

| RA-C | |

| RU |

|

- Note) For models RB and RE, refer to the tolerance of the width dimension of B1.

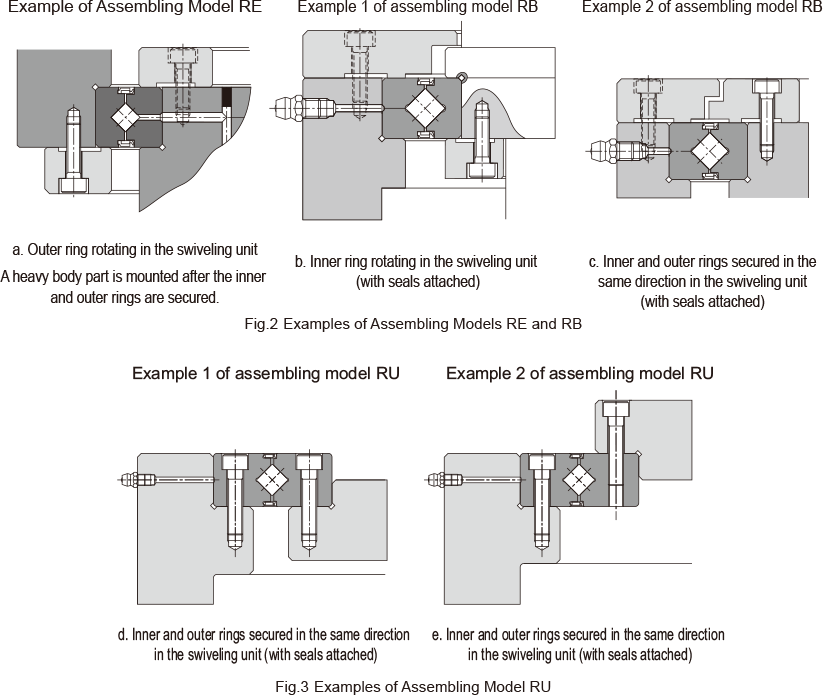

Example of Assembly

Fig.2 and Fig.3 show examples of installing the Cross-Roller Ring.

Presser Flange and Presser Bolt

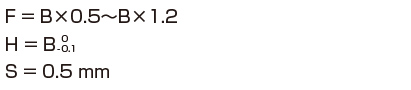

When determining the thickness of the presser flange (F) or the clearance of the flange section (S), refer to the dimensions indicated below as a guide.

As for the number of the presser bolts, the greater the number of the bolts, the more stable the system becomes. As a guide, however, it is normally appropriate to use the number of bolts indicated in Table3 and equidistantly arrange them.

Even if the shaft and the housing are made of light alloy, it is recommendable to select a steelbased material for the presser flange. When assembling model RU, use the mounting holes or tapped holes built on the inner and outer rings (model RU does not require a presser flange).When tightening the presser bolts, firmly secure them using a torque wrench or the like so that they will not loosen. Table4 shows tightening torques for the housing and presser flanges made of typical steel materials with medium hardness.

RB and RE

| Outer diameter of the outer ring (D) |

No. of bolts | Bolt size (reference value) |

|

|---|---|---|---|

| Above | Or less | ||

| - | 100 | 8 or more | M3 to M5 |

| 100 | 200 | 12 or more | M4 to M8 |

| 200 | 500 | 16 or more | M5 to M12 |

| 500 | - | 24 or more | M12 or thicker |

- Note) Please contact THK regarding the number of presser bolts and bolt sizes for models RAU, RA, and RA-C.

| Screw model No. |

Tightening torque |

Screw model No. |

Tightening torque |

|---|---|---|---|

| M2 | 0.6 | M8 | 30 |

| M2.3 | 0.8 | M10 | 70 |

| M2.6 | 1.2 | M12 | 120 |

| M3 | 2 | M16 | 200 |

| M4 | 4 | M20 | 390 |

| M5 | 9 | M22 | 530 |

| M6 | 14 |

Surface Treatment

- If the Cross-Roller Ring requires surface treatment, contact THK.

- For the details of the surface treatment, see Surface Treatment.

- Note that in the case of standard model RU and special models, it is difficult to provide surface treatment to mounting holes built on the inner and outer rings, greasing holes, etc., and a treated film may not be formed on these areas.

- Product accuracy (dimensional accuracy, rotational accuracy) is only guaranteed prior to surface treatment.