Jun 18, 2025

CSR

Safe Production with Zero Accidents! Our Safety Aims and Efforts at the Wuxi Plant

In keeping with the THK Group policy of creating safe and comfortable work environments, we work to ensure that our facilities contribute to neither illness nor injury. One of our production facilities, the Wuxi plant, sits on 55,256 m2 of land in the Xinwu district of Wuxi in China’s Jiangsu Province. The plant produces LM Guide models HSR, SSR, SRS, and HRX and employs about 600 people. Through its safety management system and various initiatives for keeping employees safe, the plant strives for safe production with zero accidents. In 2024, it even received the 2023 Outstanding Company for Safety in Manufacturing award from the Wangzhuang subdistrict of Xinwu, Wuxi. In this article, we’ll take a detailed look at what the Wuxi plant is doing to make safe production with zero accidents a reality.

Building Systems: Laying the Foundation for Safety Management

The Wuxi plant supports its safe production practices by rigorously maintaining both a system of accountability and a system for safety management. Maintaining the former creates clarity around the specific responsibilities of managers and general employees. Our safety management system, for its part, allows us to rank and manage safety risks for each area and facilitated the creation of a hazard map to keep employees informed of the level of risk associated with different work areas. By establishing operational safety rules for each of our work processes, we have laid a solid foundation for safe production activities at the Wuxi plant.

Employee Training: Developing Safety Teams

Our systems rely on the ability of our people to drive them. At the Wuxi plant, training is at the heart of safety management. From the time they join the company, all new hires participate in various trainings to develop a thorough awareness of safety and to build the skills for maintaining it. All employees participate in drills that simulate emergencies like fires, electrical shocks, and damage to machines to enhance their ability to manage a crisis. Employees also receive training on the use of AEDs and other rapid emergency responses so that our plant can minimize the harm that results even if an emergency should occur.

Managing Non-Standard Work: Lines of Defense against the Hazards of High-Risk Tasks

At the Wuxi plant, we rigorously monitor and strictly manage high-risk non-standard tasks, including work performed in high places and enclosed spaces, the operation of cranes for transferring material, forklift operation, the intake and relocation of new machines, and equipment overhauls. Before any non-standard task is begun, we conduct a detailed risk evaluation, establish comprehensive safety measures, and perform a stringent safety inspection. We also ensure that employees are equipped with proper safety equipment and designate a dedicated supervisor over the task. In this way, we create an environment in which high-risk tasks can be performed as safely as possible, doggedly holding the line against the hazards these tasks present.

Safety Activities and Training: Ongoing Initiatives for Raising Awareness

In order to maintain employees’ attention to safety, the Wuxi plant has designated June as “Safety Awareness Month.” During this month, we hold safety knowledge and skill competitions, invite employees to submit their own safety slogans, perform emergency drills, and hold a number of other events to bolster our safety culture and instill a safety-centered philosophy at our plant. Beyond this, we do danger spotting drills on a monthly basis to create a plant-wide structure in which employees are able to independently identify potential risks that arise in their day-to-day work and propose improvements to mitigate them. Through these activities, we are rigorously working to prevent accidents before they happen.

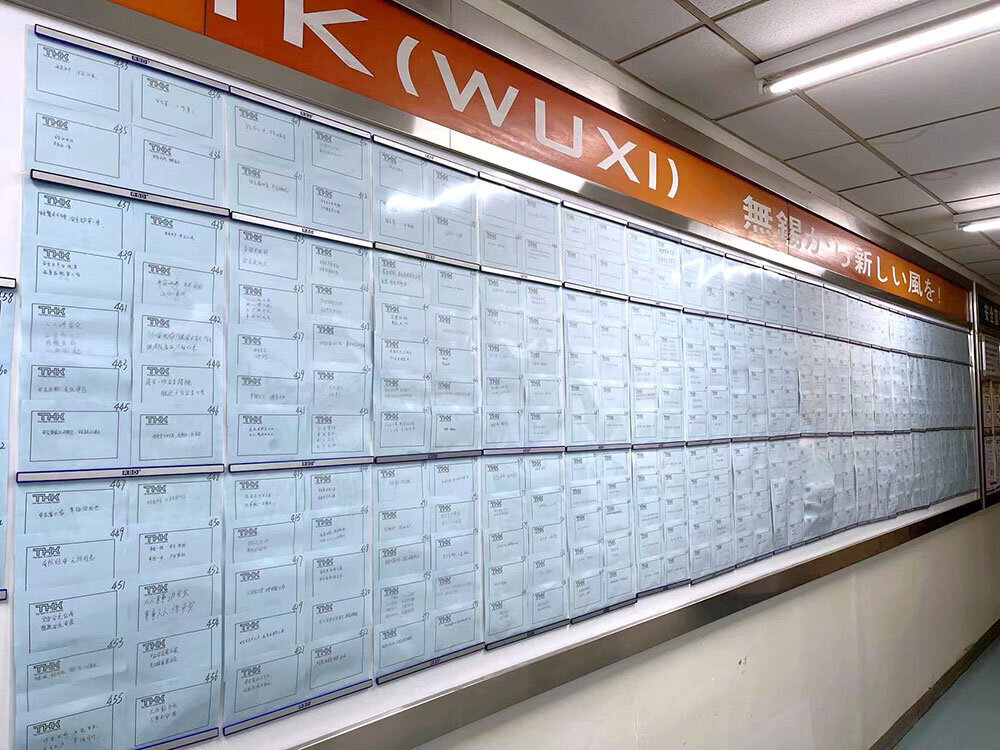

Safety Proposals and Regular Management: More Active Communication through Universal Participation

At the Wuxi plant, we are deeply aware that safety isn’t just management’s responsibility; it’s everyone’s responsibility. In keeping with this, we actively encourage employees to make suggestions about how we can improve safety at our facility in light of near misses and potential risks. We also reward and recognize effective proposals commensurate with their effectiveness to further incentivize employees to take part in our safety management system. In 2024, we received 1,004 proposals, and all of them have been implemented on the production floor. On a monthly basis, managers perform safety patrols to promote early detection and resolution of issues. We further maintain the safety of our production floor through a rotating duty system for daily workplace safety inspections. Finally, we use a monthly safety meeting to summarize and report on the progress of our safety management activities as a means of continuing to drive improvements for enhancing our management of safety overall.

Safety Systems: Raising the Bar on Intrinsic Safety

Our machines are equipped with entry detection sensors at danger points and systems that automatically stop them in the event something goes amiss. We invest in raising the intrinsic safety of our equipment like this to give our employees peace of mind in the workplace.

As a result of these efforts, we received the 2023 Outstanding Company for Safety in Manufacturing award.

Our Safety Manager’s Thoughts on Receiving the Safety in Manufacturing Award

As the plant won this award, we had a chance to speak with the Wuxi plant’s safety manager about current initiatives and future activities. This is what he had to say:

“Safety management is fundamental to protecting the lives of employees and the integrity of our assets, but it is also essential for the sustainable development of our company. Because we understand that prevention is at the heart of safety, we focus our activities on instilling in each employee a mindset that puts safety first and sees prevention as its primary driver. Thanks to the proactive support of our management team, we have been able to increase our safety activity budget and raise the intrinsic safety of our equipment. We are still laying a strong foundation for safety at the Wuxi plant and will continue to dedicate every effort to methodically building up our safety management system from it. With this award, a government agency has recognized all of our hard work to this point. At the same time, I see it as a strong encouragement for us to continue growing. Going forward, we will continue to raise the bar, ever deepening our approach to safety management.

“Our future improvement initiatives will be organized around four main pillars: (1) increasing all employees’ awareness of safety with more robust safety training and drills, (2) rigorously implementing a system of accountability for safe production to cultivate a safety culture in which all employees take part, (3) eliminating the risk of accidents through diligent management of the production floor, and (4) using more effective emergency drills to create a crisis management structure in which all employees are capable of responding appropriately to such events.”

* This content is based on information that was released in Japanese on June 18, 2025.