Jul 2, 2025

Aug 21, 2025

Products

The Humanoid Robot FRED Is Built for Speed and on Display at Expo 2025 Osaka, Kansai!

As robots become a more common sight in restaurants and hotels, humanoid robots in general are increasingly a topic of conversation. We live in an age when the technology once thought to be solely the stuff of science fiction movies has been researched and developed for commercial applications in a way that brings it into our daily lives more often than ever before. In this article, we’ll take a look at the evolution of humanoid robots and introduce THK's own humanoid robot, FRED.

The Highly Anticipated Evolution of Humanoid Robots

The term humanoid robot describes any robot made in the human image. This type of robot, which possesses two arms and walks on two legs, is likely what first springs to mind when we think of robots in general. While humanoid robots have long been anticipated as the ultimate all-purpose machines, capable of performing a variety of tasks on behalf of us humans, numerous technologies are required to make them a reality. Much as we might be looking forward to them, we still haven’t been able to replicate the kinds of robots we see in movies and comic books. That said, recent advances in AI technology have enabled rapid progress in previously challenging areas, such as smooth, highly accurate language processing, stable traversal of unfamiliar environments, and the handling of flexible objects. These developments allow humanoid robots to perform the general-purpose tasks we have come to expect of them and further heightened anticipation of their expanding role in our lives.

Developing THK’s Own Humanoid Robot

THK is pushing forward on a number of fronts toward creating the all-purpose humanoid robots of the future.

The Humanoid Robot FRED Excels in Its Physical Capabilities

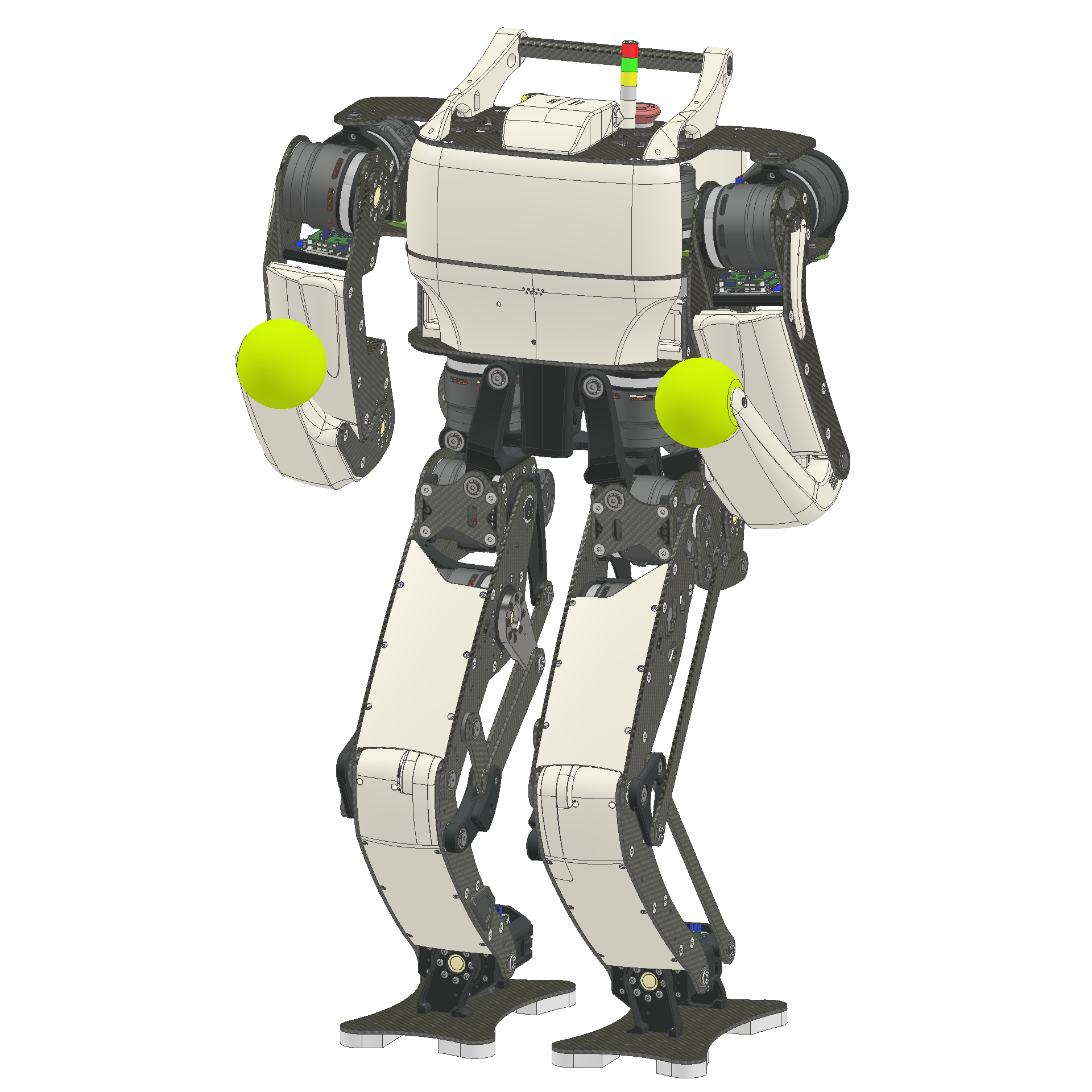

The name of THK’s humanoid robot, FRED, is an acronym for Flexible Robust Engineering Design. It serves as a statement of the kind of robot we set out to develop.

Impact-resistant actuators with high backdrivability allow FRED to achieve peak physical capabilities. FRED has the ability to flexibly absorb impacts from making contact with the ground while running at speed, performance output for high-speed motion, and high-accuracy control performance.

Humanoid Robot FRED Specifications

| Model | HR-S01 |

| Height | 1,200 mm |

| Mass | 37.3 kg |

| Leg length | 700 mm |

| Degrees of freedom | 20 (6 per leg, 4 per arm) |

Achieving the World-Class Running Speed of 13.8 km/h (3.8 m/s)!

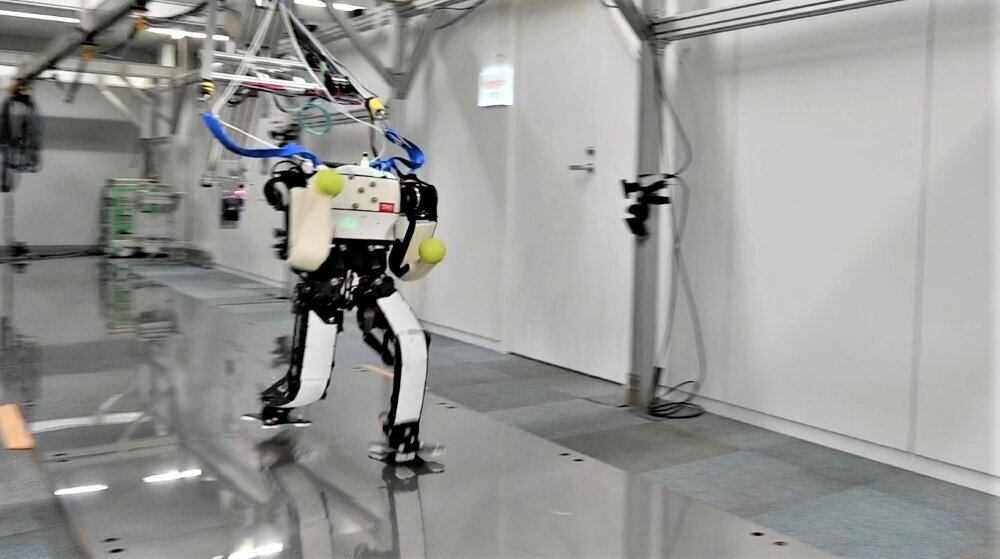

To demonstrate the high level of technological skill that went into FRED, we took it on a running test in May 2025, where it was able to reach the world-class speed of 13.8 km/h (3.8 m/s) in the field of humanoid robots.

Three technologies that were key to making FRED a reality

1. Novel leg linkage mechanisms

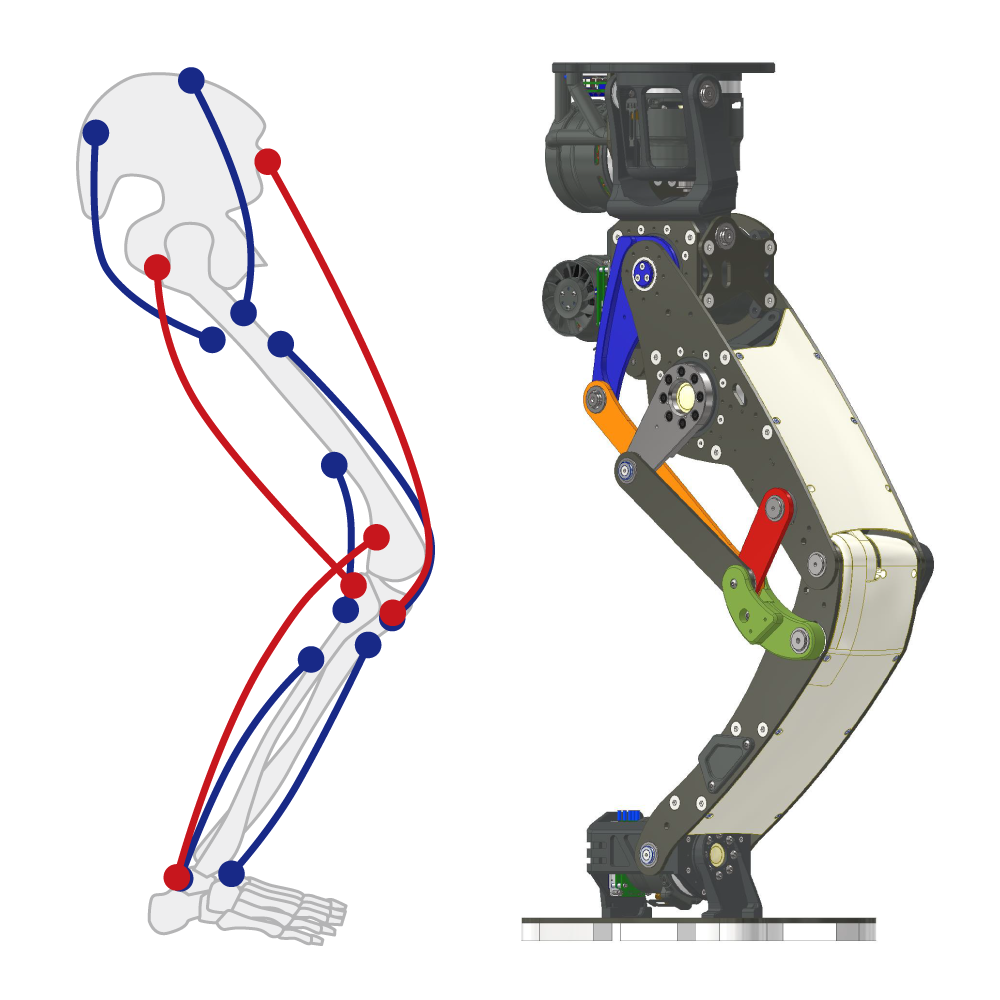

Some living things have muscles that span two joints, called biarticular muscles. It is said that these muscles are arranged so as to produce just the right amount of output force necessary to resist the pull of gravity and support the structure of the organism’s body. While we didn’t replicate the arrangement of these muscles with the humanoid robot FRED, its design does incorporate novel leg linkage mechanisms that possess dynamic characteristics similar to those of biarticular muscles. This allows FRED to flexibly absorb impacts from making contact with the ground while running and also provides enhanced control performance.

2. High-performance actuators with backdrivability and high output for their small size

Actuator backdrivability is crucial to making the structure described above work. Humanoid robots have so many drive axes that, if actuators aren’t designed to be small and light, the robot's weight will impede its function. Thus, the challenge of making small, high-output actuators is a universal one. As the ability for an actuator to move in response to external forces, backdrivability is essential for allowing a humanoid robot to move flexibly when being pushed and for enduring the force of collisions and impacts from making contact with the ground. Beyond this, we also had to take great pains to make components that could act in concert with the backdrivability and the high output from these small actuators.

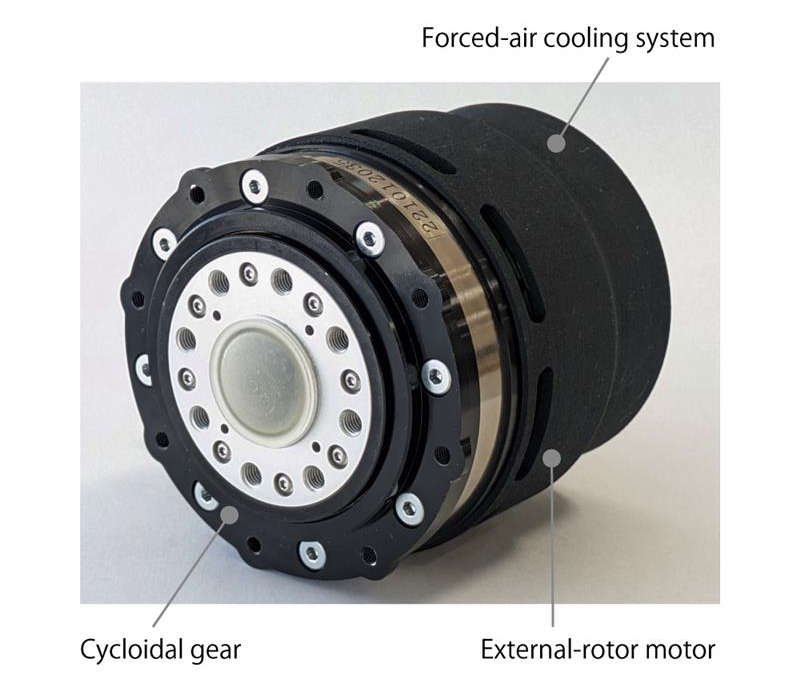

THK combined the following three technologies to take the abilities of these actuators to the next level.

(1) Cycloidal gears

With multiple teeth making contact simultaneously, these gears provide a high degree of impact resistance. The shape of these gears facilitates highly efficient power transmission and provides high backdrivability.

(2) Outer rotor motors

These motors are particularly effective with high-torque applications. Using one of them as an actuator allowed for an integrated, lightweight design. Additionally, we implemented further measures to reduce cogging torque.

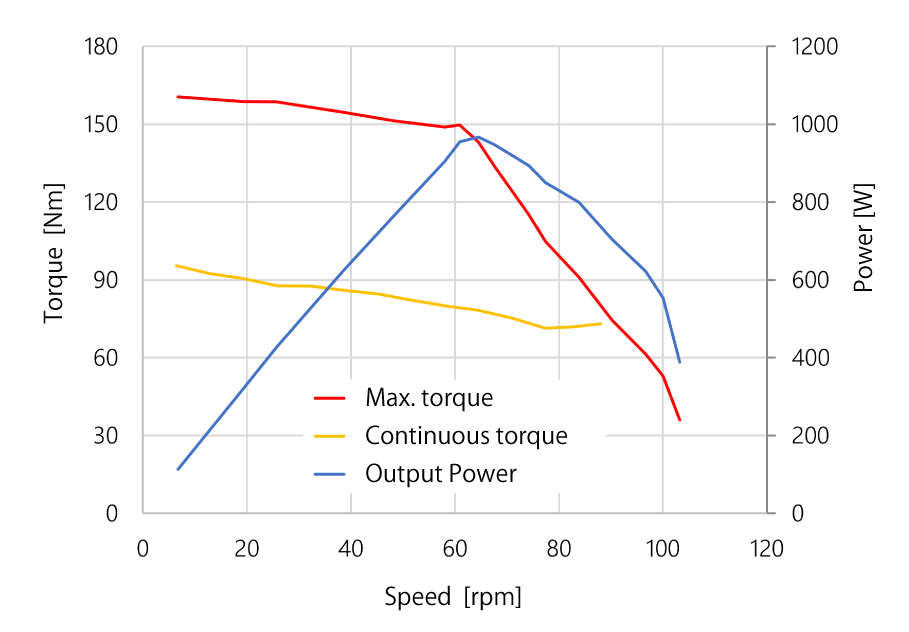

(3) Forced-air cooling systems

Incorporating an independent cooling fan motor made it possible to directly cool the motor coil for greater cooling performance. This in turn improves continuous torque in the low rotation range, where heat generation usually proves problematic.

Actuator Specifications (Reference Values)

| Model |

RA-C80-04 |

| Maximum torque |

160 Nm |

|

Maximum rotational speed |

100 rpm |

|

Maximum output |

960 W |

|

Diameter |

85 mm |

|

Length |

82.5 mm |

| Mass |

960 g (exluding motor driver) |

Video showing actuator impact resistance and backdrivability

The video at the link below shows a 20 kg weight being dropped onto a leg built with our actuators. The robot leg shows excellent impact resistance here. Not only can the leg raise and lower the 20 kg weight, it can also flexibly handle that weight dropped from above thanks to the backdrivability of the actuators.

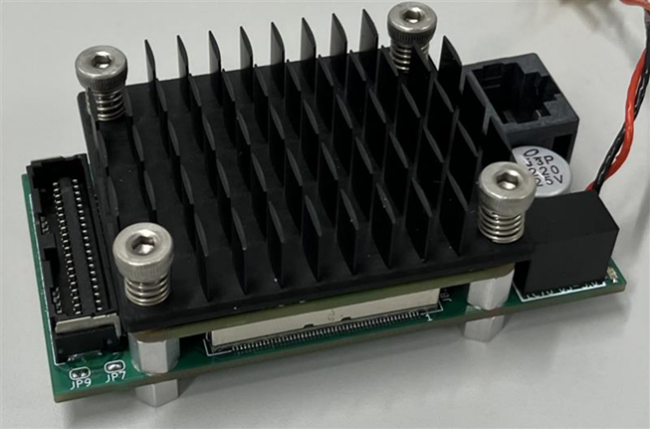

3. A robot controller capable of real-time control with 1 ms frequency

Getting a robot to move quickly requires a high-speed, accurate control system. By performing some of its transmission processing using an FPGA hardware circuit, our robot controller is capable of hard real-time control at a frequency of 1 ms. This provides stable, accurate transmission of control signals and is also noteworthy for facilitating more streamlined processing of timing on the control software side.

Envisioning the Future of THK’s Humanoid Robots

This time, we looked at the humanoid robot FRED and the technology at work inside of it. While 13.8 km/h is fast for a humanoid robot, though, it's only about as fast as an elementary schooler running at full speed, so we have a ways to go before humanoid robots catch up to humans. Humanoid robots really need to be our match for athletic ability for several of the things we want them to do on our behalf, but we aren't quite there just yet. Numerous technologies are required to enable them to not only run, but to perform the varied tasks we want them to do as well.

For its part, THK is endeavoring to produce these various technologies in order to make further strides in robot running and more. It would be very difficult for THK to pursue this path alone. The gathered wisdom of humanity at large is needed to achieve this particular feat. Though things are still in the research and development stage, THK will continue to put our cutting-edge technology to use toward new developments as we strive to contribute to the advancement of humanity as a whole.

Additionally, THK showcased the humanoid robot FRED at "Future Creation Robot Week," an event held as part of EXPO 2025 from Sunday, July 13 to Saturday, July 19, 2025, attracting numerous visitors. This event, held at the EXPO 2025, OSAKA, KANSAI venue, was an interactive and experiential event focusing on people and technologies shaping the future of robotics. Please note that this event has already concluded.

* August 21, 2025: Updated the description regarding the exhibition following the conclusion of the Future Creation Robot Week.

* This content is based on information that was released in Japanese on July 2, 2025.