Jun 12, 2024

Products

From Semiconductor Manufacturing Equipment to Machine Tools: The Unexplored Potential of the Slide Rail!

The slide rail is a linear motion guide used for the drawers of furniture and office automation devices. But did you know that the range of its applications has been growing? Its use in combination with the LM Guide has been attracting attention in recent years in industries that require environmental considerations as well as performance. Additionally, slide rails adapted to the clean environments of semiconductor manufacturing and the low temperatures of logistics warehouses have met with customer praise. In this article, we’ll take a closer look at some new example applications of the slide rail and talk about slide rails intended for special environments.

What Is a Slide Rail?

Slide rails are, in general, low-cost, finite type linear guides made by the precise shaping of a steel plate. This usually involves roll or press forming a plate of either steel or stainless steel. There are also slide rails made of drawn aluminum as well. Overall, their thin, compact design and easy installation make slide rails a type of linear guide suited to many applications.

Machine Tool Applications: Slide Rails vs. the LM Guide

In many machine tools, you’ll see LM Guide units used at both the top and bottom of where the door opens and closes. This is because machine and equipment doors on the production floor open and close frequently, meaning they require durability and smooth motion. However, while an LM Guide is appropriate for the top of the door, where it bears all of the load, a highly durable slide rail can be selected for the bottom guide, which is used as a brace. The effective combination of these two products stabilizes the motions of opening and closing, reduces the weight of the equipment, and creates energy savings. It also contributes to product cost optimization.

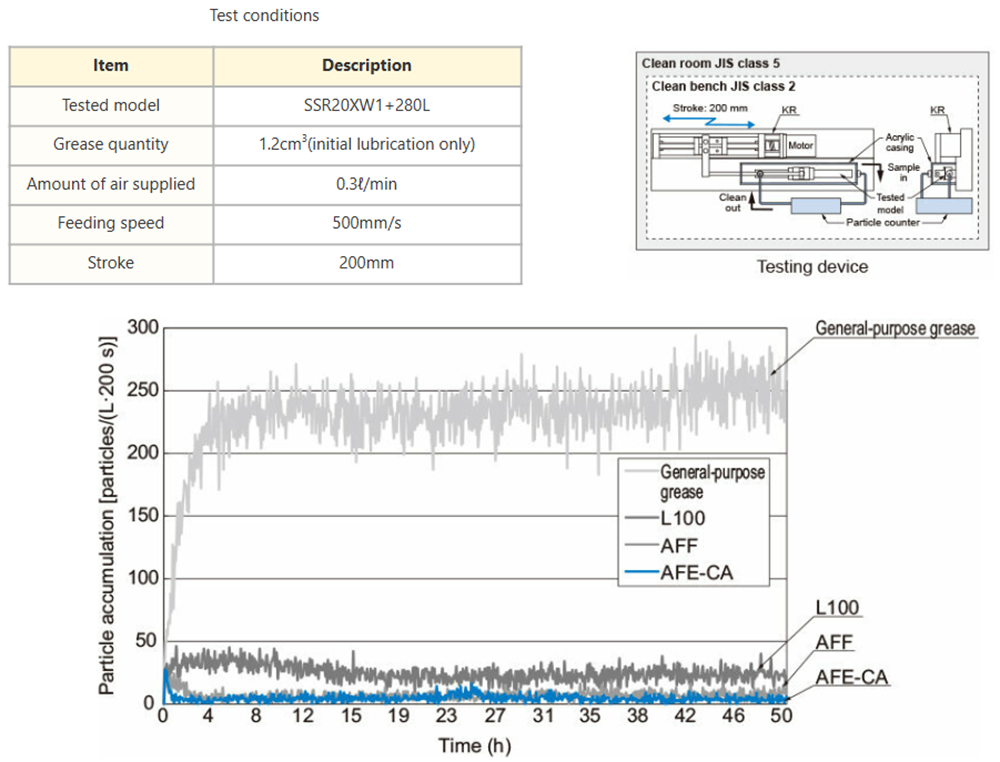

Semiconductor Manufacturing Equipment Applications: Slide Rails with Low Dust-Generating Grease

Semiconductor manufacturing requires an extremely clean environment. Here, the infiltration of even minute particles has a critical impact on production, as it can drastically diminish equipment performance. This is where slide rails for clean environments, which have low dust-generating grease, are used. The low dust-generating greases that can be selected for THK's slide rails based on equipment needs include grease optimized for the semiconductor field to be free of metallic elements and grease that provides greater extreme pressure resistance than conventional low dust-generating greases through the use of a lithium complex-based consistency enhancer and a special additive. They improve the reliability of stable motion manufacturing processes by leaps and bounds while suppressing dust generation in clean environments.

Customers have told us they haven’t been able to find a manufacturer that can deliver slide rails with low dust-generating grease already applied, and it seems that many production floors have instead turned to components with higher-than-necessary specifications or taken to washing and applying grease to rails themselves or through a partner company. THK has production facilities in Japan that produce the slide rail, and we are able to provide them to customers with grease appropriate for their application already applied. This makes design, procurement, and assembly of slide rails with low dust-generating grease more efficient.

Cold Storage Warehouse Equipment Applications: Slide Rails with Grease for Low-Temperature Environments

Slide rails are also utilized in low-temperature environments such as frozen storage and refrigerated warehouses that handle things like food. The general slide rail is recommended for room-temperature environments, as the consistency of the grease they use is increased in low temperatures, which makes the slide rails move less easily. THK slide rails that use grease for low-temperature environments, however, can handle environments as cold as -45°C while maintaining a high degree of lubricity and smooth motion. Working in frozen storage and refrigerated warehouses is highly taxing on the human body, a fact that presents a serious challenge. But slide rails that use this grease for low-temperature environments can improve work efficiency in ways that contribute to reducing time spent working in these environments and the burden this places on workers. Using the highly stable and reliable slide rail enables smooth operations in automated warehouse systems as well, where large volumes of product must be handled in a short amount of time and high durability without errors is required.

While deciding on product specifications for each item and piece of equipment, such as thin, compact slide rails for the shelves of the increasingly high-mix, low-volume frozen food industry or high-rigidity ones for shelves used for frozen livestock and marine imports, which are often exported in bulk, selecting a grease appropriate for the environment results in increased productivity.

The Slide Rail’s Expanding Range of Available Specifications, Accessories, and Special Order Options

The same slide rails that are traditionally used for control panels and more generic unit drawers are also utilized in various places on and around the kind of machine tools, semiconductor manufacturing equipment, and logistics warehouse equipment introduced in this article. Slide rails with a locking mechanism attached make it possible to fix a drawer in place during maintenance work, making it quick and easy for a worker to gain access to the inside of a piece of equipment and increasing the efficiency of their work. This locking mechanism can also provide a safer working environment by preventing things like having the machine shut that drawer unexpectedly. This keeps workers safe and reduces maintenance time, and it contributes to minimizing the time a production line is down. Slide rails with tabs, on the other hand, can be attached by hooking said tabs in a way that eliminates the need for conventional screw fastening, which reduces the labor associated with equipment assembly, lessens the burden on workers, and can be expected to improve the quality of their work as well. As we continue to expand the slide rail specifications and options we offer to meet a variety of needs, choosing a different THK product that matches your applications and goals may yet yield unexpected improvements at your facility.

THK can flexibly alter the length of its slide rails and their strokes and make precise adjustments to slide rail specifications tailored to a given unit or machine. As mentioned above, we are also able to deliver them with environment-specific grease already applied. Please consider our slide rails for shortening your production lead times and optimizing product costs.

In this article, we introduced some new example applications of the slide rail and talked about slide rails intended for special environments. While the slide rail is more often referred to as hardware rather than a machine component, THK's slide rails continue to evolve, offering a high degree of durability and an ever-expanding range of specifications, accessories, and special order options. THK can propose products suited to your situation beyond the example applications introduced above. If you’re interested, don’t hesitate to contact us.

* This content is based on information that was released in Japanese on June 12, 2024.

Contact information

Please direct product inquiries to:

Application Engineering Department

2-12-10 Shibaura, Minato-ku, Tokyo 108-8506, Japan

Phone: +81-3-5730-3865 Fax: +81-3-5730-3918

Inquiry Form