Nov 13, 2024

Products

When Disaster Strikes! Seismic Isolation for Equipment as Part of a Business Continuity Plan

In a perfect world, none of us would have to worry about the chaos created by natural disasters and the spread of disease. In reality, however, it is impossible to prevent the unpredictable. What assurance can we have, then, that our organizations will be able to continue conducting business in the face of events such as these? This time, we’ll be exploring what kind of countermeasures are required for business continuity during an emergency and looking at a concrete example of earthquake countermeasures that utilize THK seismic isolation for equipment.

What Is a Business Continuity Plan?

A business continuity plan (BCP) aims to maintain business operations and facilitate quick recovery while ensuring employee safety in order to minimize the impact that a sudden change in the environment, such as a disaster or a disease event like the coronavirus pandemic, has on employees and corporate resources. Such preparations have been essential for businesses to ensure employee safety and continue to operate in the wake of natural disasters created by recent changes to the environment. BCPs started getting renewed attention as a result of the impact that the 2011 Great East Japan Earthquake had on numerous companies.

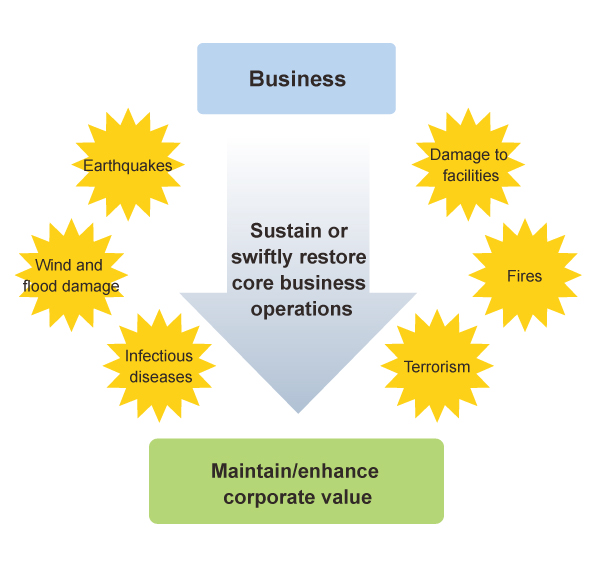

Two Major Goals of BCP Implementation

Protecting employees and the company

The most valuable asset a company has is its employees. They are the ones who sustain and grow the business. In the event of a natural disaster or a pandemic, employees must be protected and measures taken so that they can continue their work with safety and peace of mind.

Increasing company value

Faced with an emergency, if a business can either minimize damage and maintain its core operations or make a quick recovery, it can avoid going bankrupt or having to scale down. It will also be more appealing to job-seekers as a business that offers long-term job security. Furthermore, its ability to maintain customer trust will see it rated highly by those involved in the market, which will ultimately sustain and increase its value.

Created by THK CO., LTD. based on a diagram on the website of the Ministry of Economy, Trade and Industry’s Small and Medium Enterprise Agency (https://www.chusho.meti.go.jp/keiei/antei/download/110728JapanBCP_SME_Eng.pdf)

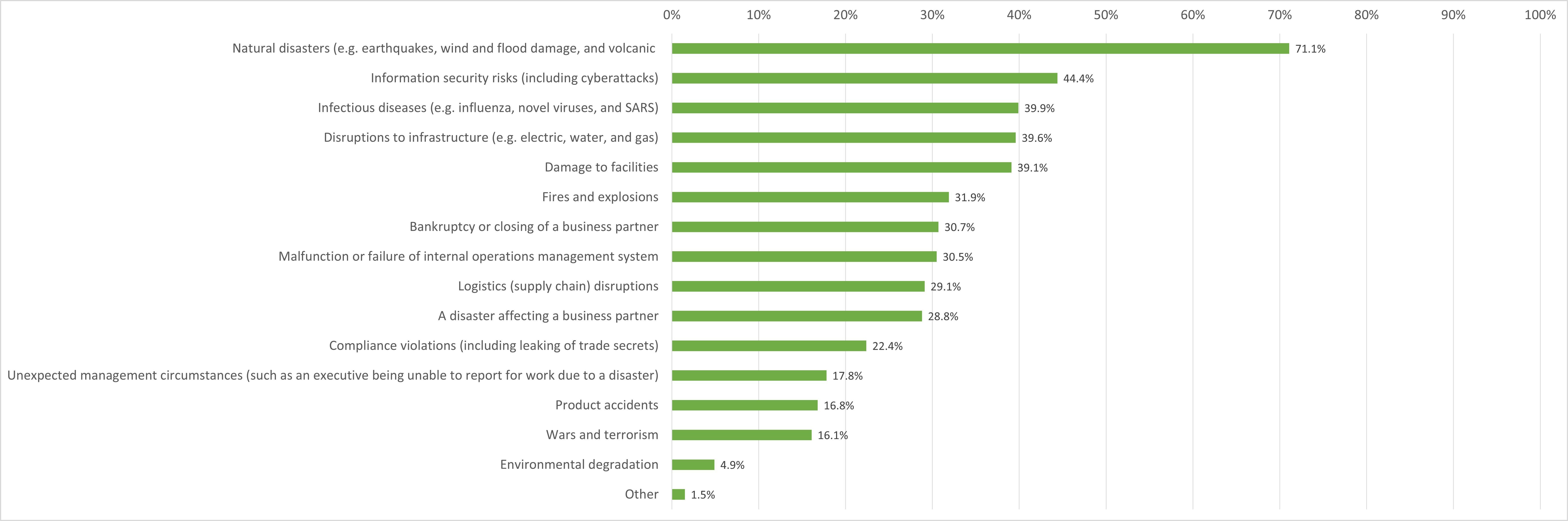

Risks Anticipated by BCPs

The graph below looks at some of the risks that a business can anticipate. Among these risks, we see that natural disasters pose the greatest potential threat to a business. Japan, in particular, experiences earthquakes that damage equipment counted among a company’s assets and disrupt supply chains. In light of this, it is crucial to put sufficient measures in place against such foreseeable risks.

Note: This information is from 5,705 companies that selected at least one response and have created a BCP, are in the process of doing so, or are considering doing so.

Source: TEIKOKU DATABANK, LTD., “Survey of Corporate Attitudes Towards Business Continuity Plan (BCP) (2024)”

https://www.tdb.co.jp/report/economic/7llbf4-_jo/ (Available in Japanese only.)

Examples of Corporate Disasters Caused by Earthquakes

As an earthquake-prone country, Japan has seen seismic activity result in a number of devastating corporate disasters. These are just a few representative examples.

- Niigata Chuetsu Earthquake (10/23/2004)

A semiconductor factory faced operational challenges as a direct result of losing customers in the time it took them to recover.

- Niigata Chuetsu Oki Earthquake (7/16/2007)

Damage to a factory making engine components impacted many automotive manufacturers.

Automotive production for July 2007 was reduced by 130,000 units to a total of 876,000 units.

Sources: Monthly Motor Vehicle Statistics Report (Japan Automobile Manufacturers Association)

Report on the Japanese Economy 2007 to 2008 (Cabinet Office)

- Great East Japan Earthquake (3/11/2011)

Many factories were damaged, halting the supply of raw materials and component parts and stifling production in a way that impacted supply chains all over Japan and around the world.

- Kumamoto Earthquake (4/14 and 4/16/2016)

A semiconductor factory and a component manufacturer suffered damage.

Damage Done to Factories by the Great East Japan Earthquake

The Great East Japan Earthquake affected many companies across a wide area, damaging equipment and facilities alike. Production ground to a halt, which in turn caused supply chains to collapse. While the impact was certainly felt in Japan, it extended to other countries as well. In the end, the quake became a catalyst for increased discussion around installing seismic isolation systems for critical factory devices and equipment as a way of minimizing both damage and disruption to production.

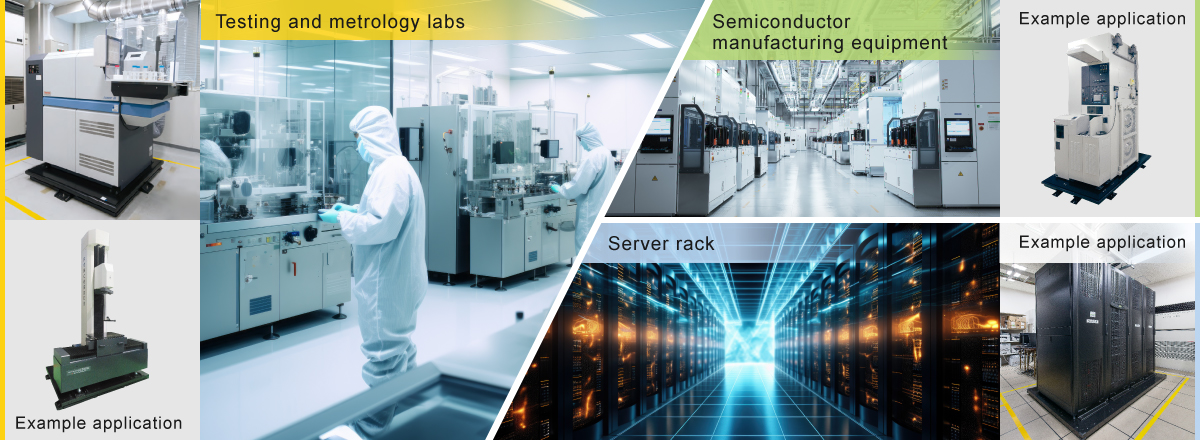

Protecting Factories and Production Floors with Seismic Isolation for Equipment

Seismic isolation systems for equipment are being used in an increasingly wide array of applications. While they are naturally suited to protecting expensive, critical objects like semiconductor manufacturing equipment, 3D measuring equipment, and a variety of inspection machines, they are also being installed on shelving units where valuable finished products and in-process inventory are stored.

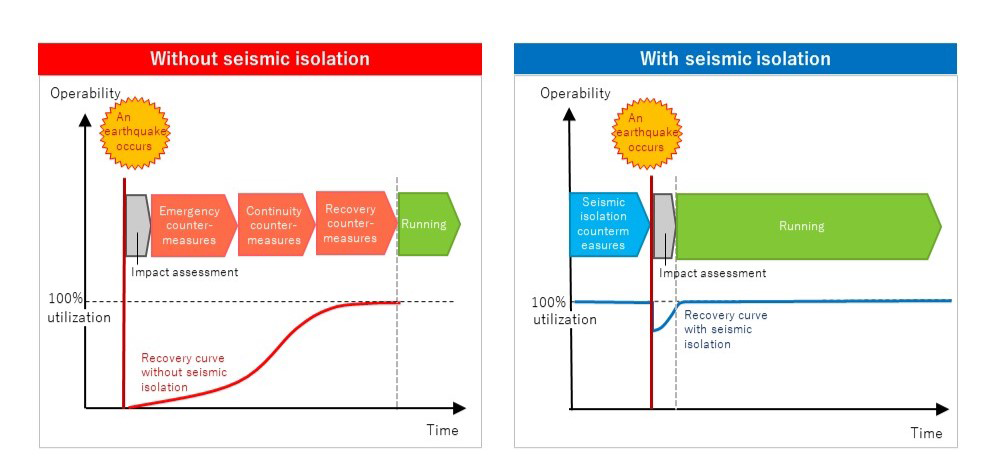

Benefits of Installing Seismic Isolation for Equipment

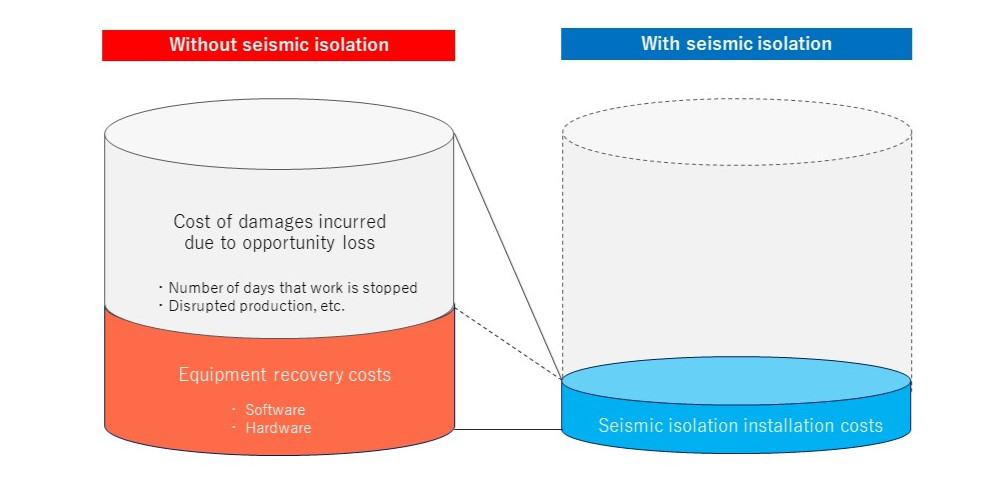

As shown in the diagrams below, two benefits we can expect to see from installing seismic isolation for equipment are faster recovery and overall cost reduction.

Installing seismic isolation provides (1) quick recovery and (2) overall cost reduction in the event of an earthquake.

Compared to the benefit of quick recovery from an earthquake provided by seismic isolation, we can see that conventional approaches without it require impact assessments followed by the implementation of emergency, continuity, and recovery countermeasures before operations can finally resume. The greater the extent of the damage, the longer it will take to resume operations and, in turn, the greater the opportunity loss will be. For some companies, this will spell bankruptcy. With seismic isolation, however, operations can be resumed either immediately after a disaster or after the subsequent impact assessment. This makes a huge difference in the amount of time it takes to restore operations and minimizes opportunity loss overall.

The second benefit of installing seismic isolation is overall cost reduction. Not having this kind of countermeasure in place when an earthquake occurs runs the risk of skyrocketing damages arising from equipment recovery costs as well as opportunity loss incurred with production and work being stopped during the recovery period. By contrast, seismic isolation may involve initial installation costs, but the elimination of costs associated with equipment recovery and opportunity loss makes for substantially lower costs overall.

Quick recovery and overall cost reduction are the two key benefits reaped by installing seismic isolation for equipment.

In addition to the seismic isolation system for equipment we looked at this time, THK also offers a lineup of seismic isolation systems that includes models that can be used for entire floors. No one knows when an earthquake might strike. It might be a good idea to consider countermeasures to prepare for the unpredictable. Please don’t hesitate to contact THK's ACE Division to find out more about our seismic isolation systems.

* This content is based on information that was released in Japanese on November 13, 2024.