May 17, 2023

Products

Tool Monitoring AI Solution Detects Cutting Tool Conditions and Prevents Defects!

If you install sensors and communication devices on various things connected to the internet, those things will be able to communicate with each other and exchange information through the IoT (Internet of Things). This can generate value for business and people's lives through automation and efficiency improvements. Let’s take a look at the IoT solutions that THK offers.

THK’s IoT Solution “OMNIedge”

As a machine component manufacturer, THK has been using its digital capabilities to offer solutions for reducing various types of loss on the production floor since 2020.

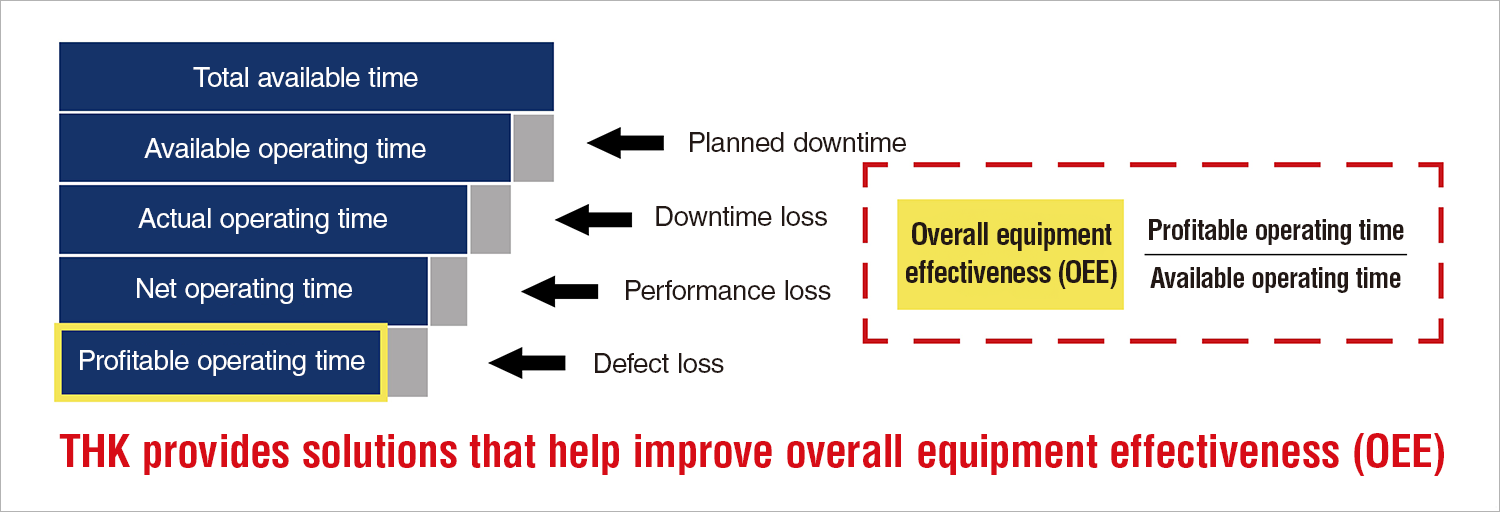

The first phase, released in 2020 and 2021, was for linear motion components such as the LM Guide, ball screws, and actuators, while the second phase, released in 2022, was for rotary components. At the same time as the number of compatible products has steadily expanded, OMNIedge was also quickly made available outside of Japan. This IoT solution was initially only compatible with THK products, but we are now steadily releasing new versions that can reduce loss and improve overall equipment effectiveness (OEE) for non-THK components.

* OEE (overall equipment effectiveness): A methodology proposed by the Japan Institute of Plant Maintenance.

Struggles That Production Facilities Experience with Cutting Tools

Many production facilities that use machine tools experience difficulties related to cutting tools.

-

Chipped cutting tools cause defects and the need for rework, leading to time losses.

-

Cutting tool costs add up significantly over time, and recent tool price increases have exacerbated the problem.

In particular, we hear stories about automated machines that were left running at night, and when everyone came in the next morning, they found that defects happened due to chipping, so they had to either throw everything away or quickly assign employees to rework and inspect those products.

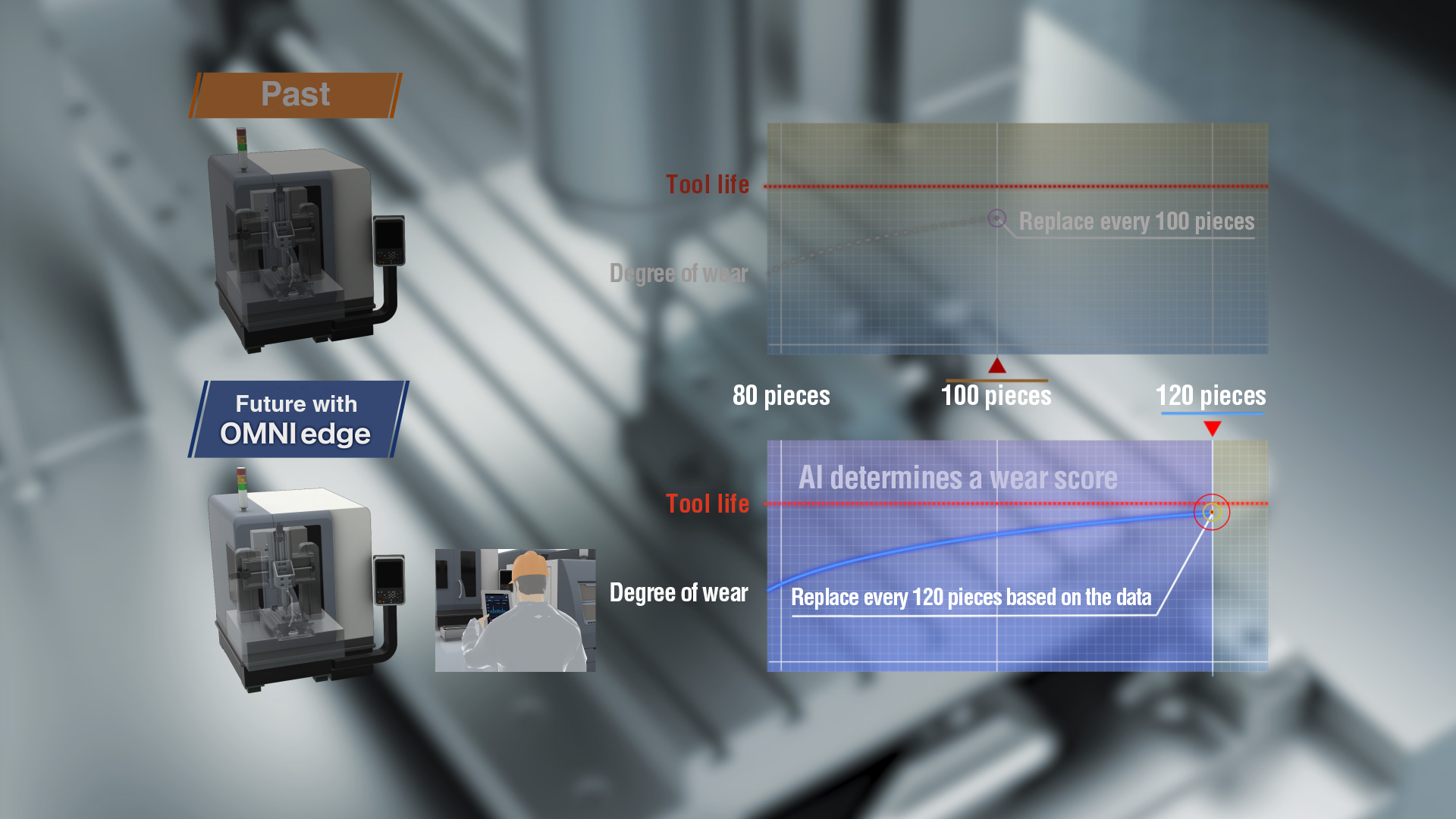

Even when it comes to the replacement of cutting tools, we hear from many companies that they’ve traditionally managed the process by piece count. When they experienced problems with chipping and tool damage in the past, they would set the replacement frequency with a safety buffer factored in, which would considerably shorten the tool's true service life. Even though they could have still used these tools, they had to replace them, which meant costs would pile up.

A lot of customers mention experiencing these types of struggles with their cutting tools, but one problem they also have is the fact that they haven't introduced the IoT to the equipment and devices on their production floor. These customers are concerned that IoT functionality is available on their newest equipment, but not their legacy equipment, so they can’t move forward at a unified pace.

Tool Monitoring AI Solution Reduces Losses Caused by Cutting Tools

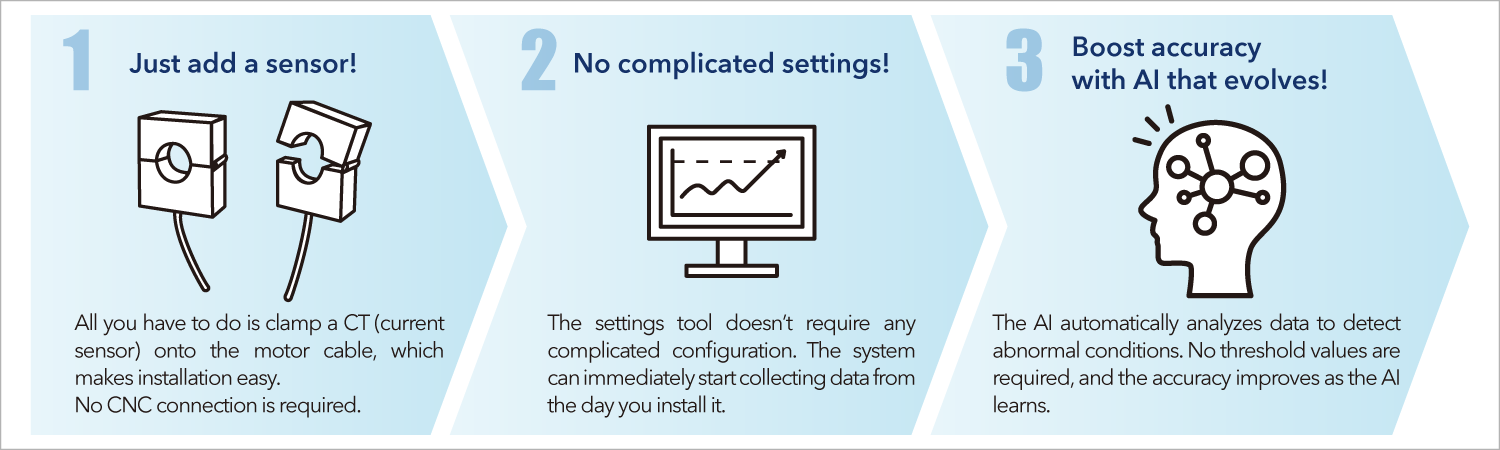

Out of a desire to alleviate these struggles with a solution that incorporates AI, THK developed the Tool Monitoring AI Solution, which measures the state of cutting tools through a sensor that can even be retrofit onto existing machine tools. This system has been praised for how it can be used without worry, as it doesn’t even need to be connected with CNC.

Main benefits:

It is estimated that there are close to one million machine tools (those with NC) in active service in Japan, and almost half of them have been in use for over 15 years.

The Tool Monitoring AI Solution is a system where a sensor can be retrofit onto existing, in-service machines, just like the OMNIedge predictive failure detection AI solution for linear and rotary components. Because the installation of this service is just a simple procedure of clamping a CT (current sensor) to each of the motor cables inside the control panel of the machine tool, the installation time is also extremely quick. As mentioned before, this system does not require a CNC connection, so not only can you feel confident about using it, but you can also curb external costs to achieve connectivity. All you have to do is install the sensor, so you can implement the system without any restrictions from the machine tool or CNC manufacturer.

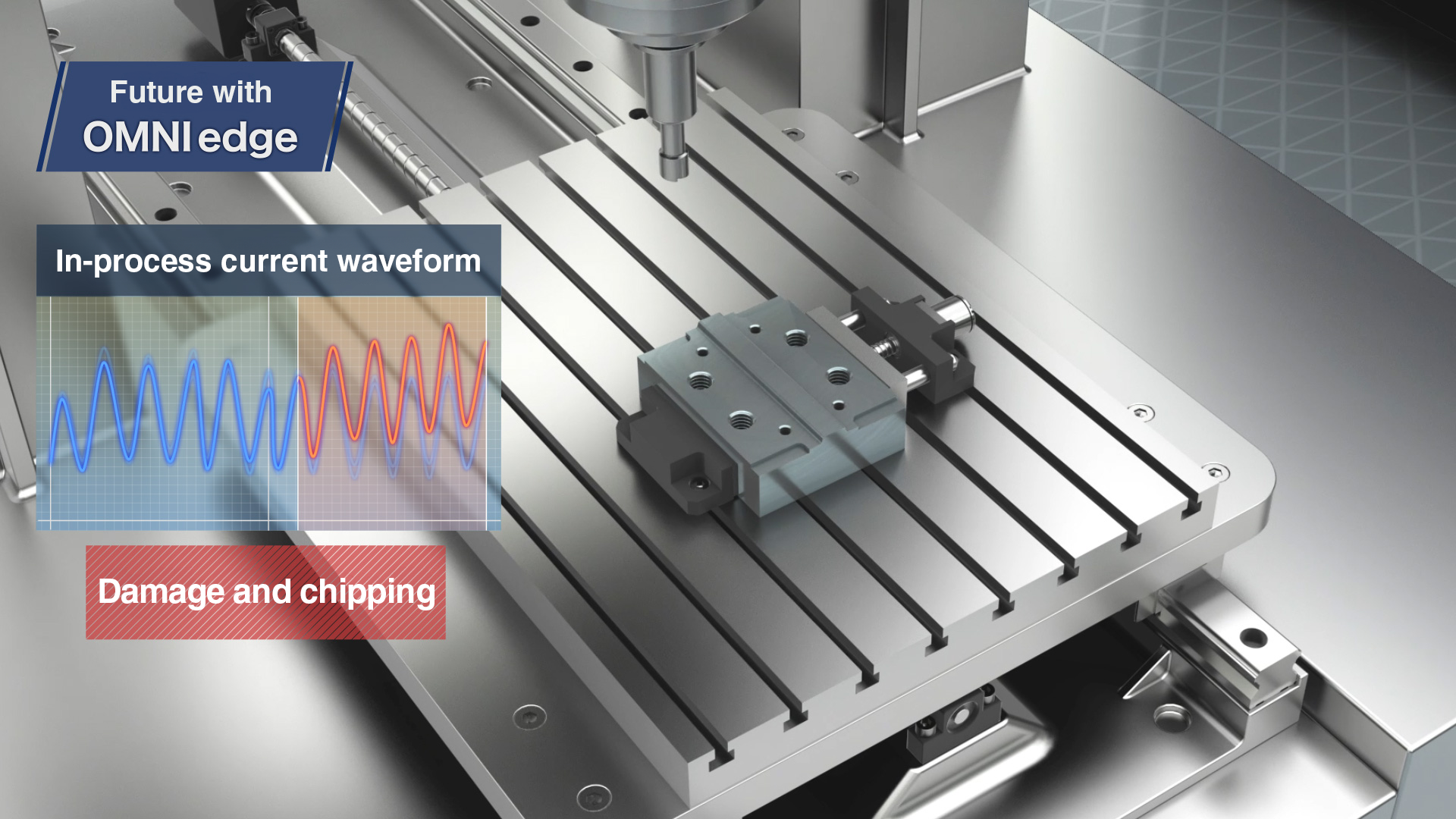

The second feature of the Tool Monitoring AI Solution is that there is no complicated software configuration required. Once you register a process, you can easily obtain data just by configuring the cutting tool replacement history on a tablet. The AI will extract feature values and automatically perform an analysis based on the collected data, and you will receive a notification when it detects an irregular waveform that occurs when a cutting tool is chipped or damaged. In the previous example of automated equipment running at night, this would allow the process to stop before large volumes of defective parts are created.

The Tool Monitoring AI Solution also allows you to work on resetting the cutting tool life by monitoring the degree of wear. First, the AI rates the degree of wear. It plots the trend of wear that occurs before replacement under normal conditions, which you can compare with the degree of wear after replacement. When it seems that you can get more life out of a tool, you can confirm the quality of the products being made and raise the target number of pieces before replacement. The system will send an alert if wear becomes more severe before that point, so you can optimize the replacement timing.

Customers Who Should Consider Implementation

Just as the name suggests, machine users that utilize machine tools are the target customer of THK’s AI Tool Monitoring System We believe this is a solution for customers who machine automotive components—especially engines, suspensions, and brake components—and would like to lower costs by optimizing cutting tool life, reduce defects caused by chipping, and reduce rework loss. In this day and age of cutting tool price increases and more and more customers dealing with intensifying cost-related problems, these customers will be able to feel the high return on investment when considering the potential losses averted. of cutting tool price increases and more and more customers dealing with intensifying cost-related problems, these customers will be able to feel the high return on investment when considering the potential losses averted.

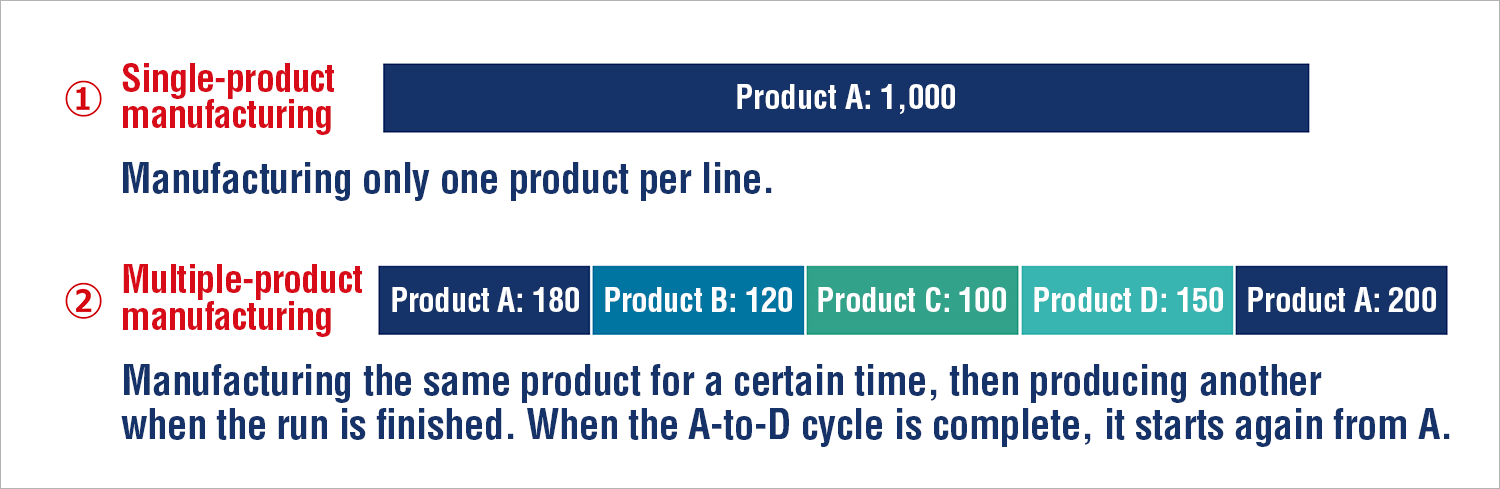

In addition, this solution is effective for customers whose machines process the same product continuously or whose lines manufacture multiple products.

If you've struggled with cutting tools or had a problem occur in the past, please reach out to us.

These struggles aren't limited to machine users in Japan, so we plan to gradually make this solution available to factories around the world.

Website for OMNIedge IoT service for manufacturing (THK website)

* This content is based on information that was released in Japanese on May 17, 2023.