Aug 27, 2025

Products

A Low-Magnetic Permeability LM Guide for Strong Magnetic Fields

The rapid evolution of technology in recent years has spurred the development of new applications for magnetic fields in a variety of industries, ranging from medical devices like MRI machines to semiconductor-related equipment like electron-beam lithography systems. In this article, we’ll look at the performance factors required of linear motion components being used inside of magnetic fields and highlight a low-magnetic permeability LM Guide that can be used in such environments.

Metals and Magnetic Fields

Just what is a magnetic field, though? Well, magnets and electrical currents generate a force called magnetism around themselves that attracts or repels different metals. The space where this magnetism is generated is what we call a magnetic field. You probably remember playing with magnets as a child, seeing what they did as you pushed them closer to various objects. You may also remember that almost anything made of metal would stick to the magnet, while anything made of plastic would not. Most people may even have seen how something like a paper clip, after it has been set close to a magnet long enough, will start to act like a magnet itself, pulling other paper clips to it even after the magnet has been removed. Things that can be so strongly magnetized by a magnetic field are called ferromagnetic materials. One of the most familiar of these materials is the metal iron.

Technologies That Use Magnetic Fields

Iron is inexpensive, easy to work with, and used in countless things all around us. It is a pillar of the modern comforts and conveniences we enjoy. That said, there are also places where ferromagnetic materials like iron simply cannot be used.

The Medical Industry: MRI (Magnetic Resonance Imaging) Machines

The MRI machines used in clinical settings might be a familiar example of this. During an MRI scan, these machines generate a powerful magnetic field that is used to create an image of the inside of a person’s body. Being essentially one large, powerful magnet, an MRI machine would pull on something made of a ferromagnetic material like iron with dangerous force. This is why patients have to remove anything made of metal from their person before the scan can begin. It’s also the reason that equipment located near an MRI machine has to be made of materials that resist the effects of a magnetic field.

The Semiconductor Industry: Electron-Beam Lithography Systems

Ferromagnetic materials are also incompatible with electron-beam lithography systems, a type of equipment related to semiconductors. As the name suggests, these systems use an electron beam to draw electronic circuit patterns. With today's technology, these systems can draw circuits with line widths as fine as 2 nm (2 millionths of a millimeter).

However, if anything around these devices exerts even the slightest bit of magnetism, the resulting magnetic field can bend the electron beam, making it difficult to draw the desired circuit accurately. Thus, in order to draw circuits accurately, these systems require components made of materials that either lack magnetism altogether or generate only the smallest of magnetic fields.

Specifications Required for Machine Components in Magnetic Fields

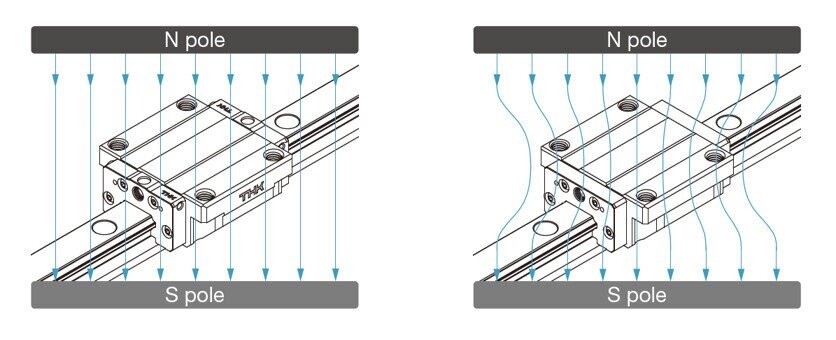

Relative magnetic permeability is the metric used to describe how much a material is affected by a magnetic field. It is expressed as the ratio of a given material’s magnetic permeability to the magnetic permeability of a vacuum, and the closer it is to 1, the less a magnetic field will affect the material in question. The types of iron normally used for machine components are said to have relative magnetic permeabilities between 50 and 5,000.

While requirements vary by machine, metals with such low relative magnetic permeability (low-magnetic permeability metals) are essential in places where MRI machines, electron-beam lithography systems, and similar devices use metal components.

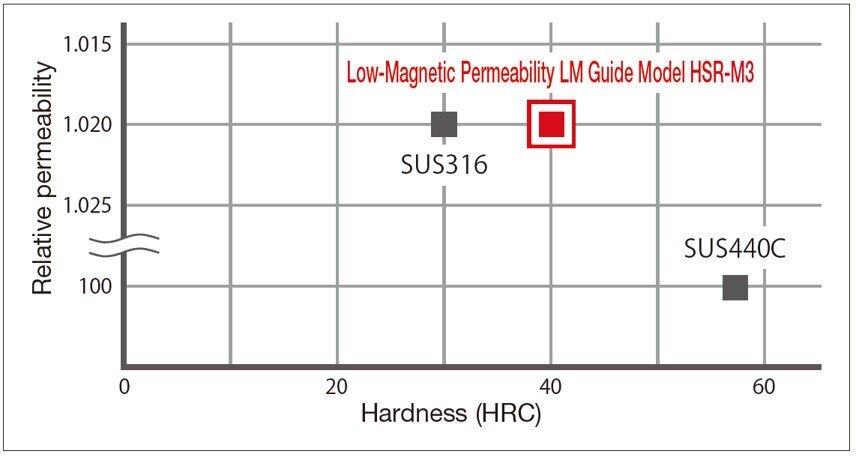

Low magnetic permeability alone, however, is not enough. For instance, a surface hardness of HRC 60 is usually considered appropriate for metals used to make machine components. Low-magnetic permeability materials like SUS316, however, tend to have surface hardnesses around HRC 30, which is relatively low. These materials just don’t provide sufficient surface hardness for use in machine components, as they would reduce both part performance and service life. Conventional materials like this essentially force a trade-off between low magnetic permeability and surface hardness.

How, then, can we provide both when it comes to machine components predominantly made using a ferromagnetic material like iron?

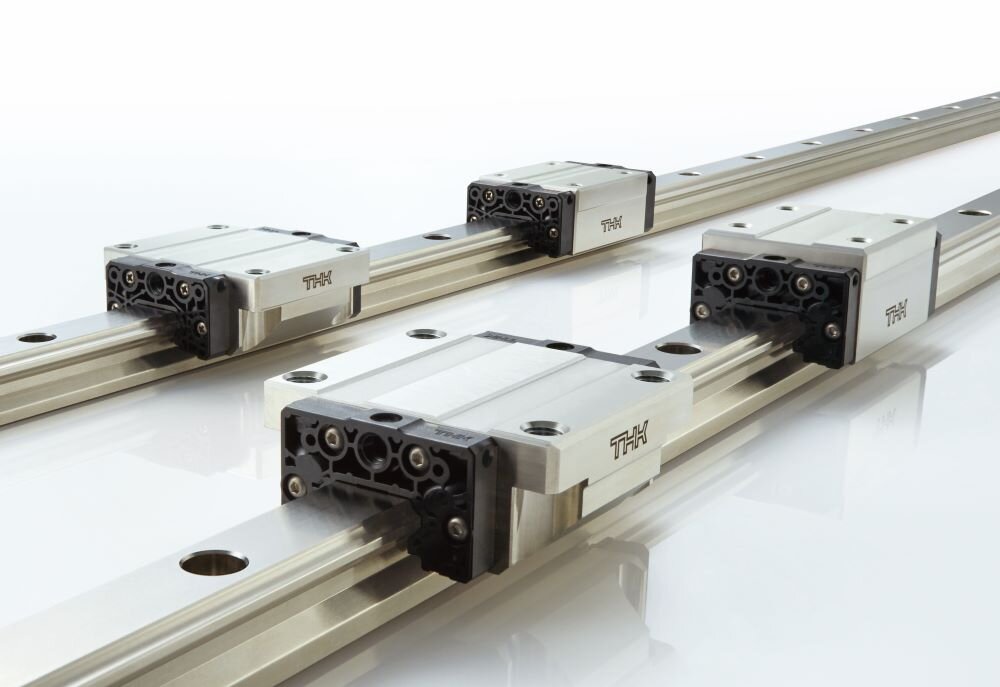

The Low-Magnetic Permeability LM Guide Model HSR-M3

THK developed the Low-Magnetic Permeability LM Guide Model HSR-M3 to be able to resist the effects of magnetic fields so that it can be used in MRI machines, testing equipment, and other devices that generate strong magnetic fields. Its biggest selling point is its low magnetic permeability. Thanks to the special material used to make it, it boasts an extremely low relative magnetic permeability of 1.02. With an LM rail and LM block made of this material, it is capable of achieving maximum performance even when exposed to magnetic fields, making such factors a non-issue during design.

Beyond its low magnetic permeability, the material used to make the Model HSR-M3 also has a surface hardness of HRC 40, which is higher than most other low-magnetic permeability materials and affords the Model HSR-M3 a larger load rating. This allows for substantially greater design flexibility, as the increased load that the LM Guide can tolerate makes it possible to situate a loaded object’s center of gravity even farther away from the guide itself.

The Low-Magnetic Permeability LM Guide Model HSR-M3 is part of the Model HSR series which, even among THK's LM Guide products, has a long history of being used in various machines around the world. It also conforms to ISO standard dimensions. As a Model HSR product, it too combines self-adjustment capabilities that absorb mounting errors and the four-way equal load feature that allows it to be mounted in a variety of orientations, meaning it can be installed in existing equipment without requiring any major design changes.

In the past, LM Guide units with low magnetic permeability were only offered as custom products. Now, though, the Model HSR-M3 is officially part of our standard lineup. We hope this makes product selection that much less time-consuming for our customers.

Reliable Linear Motion Even in Strong Magnetic Fields

In this article, we looked at the performance factors required of linear motion components being used inside of magnetic fields and introduced the Low-Magnetic Permeability LM Guide Model HSR-M3. As equipment accuracy and performance continue to improve, we imagine there will be increasing demand for products with low magnetic permeability. If you’re trying to figure out what machine components to use in an environment exposed to magnetic fields, don't hesitate to contact THK for support.

Details about the Low-Magnetic Permeability LM Guide Model HSR-M3 (THK website)* This content is based on information that was released in Japanese on August 27, 2025.