Apr 30, 2025

Products

Supporting Aircraft Safety: THK's Quality Assurance and Track Record

Recent technological developments have hastened innovation in a number of fields, and developments in the fields of robotics and the IoT have garnered particular attention. These technologies are likely to be adapted for a wide range of applications, including smart factories, self-driving vehicles, medical equipment, and renewable energy. As they are increasingly adopted, however, quality control for the products that go into them will be ever more critical. Work in the aviation sector, for instance, requires certification under the ISO 9001 international quality control system standard or the even stricter JIS Q 9100 standard for quality management systems in the aerospace and defense industries. Well aware of the importance of these technological innovations and the critical nature of quality control, THK has already begun making inroads into this sector. This time, we’ll be looking at the future outlook for the burgeoning aviation sector and how THK’s quality control initiatives and product development tie into that future.

The Latest Trends in the Aviation Sector

The modern aviation sector saw passenger numbers plummet in 2020 and 2021 as a result of the coronavirus (COVID-19) pandemic. As economic activity returned to normal, however, each airline saw revenue recover to pre-pandemic levels. Furthermore, current forecasts of 3% to 4% annual growth* are expected to increase to an average of 5% to 6% by 2032 as the sector continues to expand. With demand for commercial aircraft increasing in particular, adoption of sustainable aviation technology is proceeding apace.

When it comes to materials, the biggest challenges faced by the aviation industry are developing materials that are lightweight, strong, and durable and controlling production costs. As fuel efficiency and reduced CO2 emissions are increasingly prioritized, aircraft must be made ever lighter without sacrificing strength, safety, durability, and corrosion resistance. Furthermore, improvements to the efficiency and environmental impact of aircraft are expected alongside increased demand for lightweight materials and advanced electrical systems. With the likelihood of more proactive capital investment being high, the future promises robust growth for the aviation sector.

Source: Ministry of Economy, Trade and Industry. Concerning the Future Direction of the Aircraft Industry in Japan. March 27, 2024

https://www.meti.go.jp/shingikai/sankoshin/seizo_sangyo/kokuki_uchu/pdf/2023_001_02_00.pdf (Available in Japanese only.)

The Aviation Industry’s Strict Quality Control

Safety and reliability are extremely important factors of quality control for products bound for the aviation sector. A defect in any part or system can lead to a major incident that endangers the lives of the many passengers an airplane carries. In recognition of this, THK manages the following items very stringently when it comes to our products for aviation.

Quality management system (QMS) implementation

Certification under the quality requirements of the JIS Q 9100 standard for quality management systems in the aerospace and defense industries is essential for THK to expand its sales into the aviation sector. JIS Q 9100 is a quality management system based on ISO 9001 that incorporates quality factors required by airframe and aircraft engine manufacturers. The system’s standard was first published in Japan in 1999. Companies that obtain JIS Q 9100 certification are added to an online registry, which earns them greater global recognition and indicates that their products meet safety standards. Within the THK Group, THK NIIGATA obtained JIS Q 9100 certification for its ball splines for aircraft controls in 2009 and now provides these products to the aviation sector.

Risk management

Accommodating customer-specific requirements when developing products for the aerospace industry can incur certain risks. Accordingly, THK limits the risks it incurs to those involved in ordering, design and development, purchasing, manufacturing, and inspection; clarifies how it controls the likelihood, impact, and severity of these risks; and conducts risk assessments.

Key characteristics management

In order to control product variance, THK performs key characteristic management* by determining permissible values and, as necessary, performs and records the results of inspections at each manufacturing process and quickly discovers and removes defects. We employ first article inspections (FAIs) and a final inspection process to ensure that our products are manufactured as designed.

* Key characteristic management: The process of identifying and managing variance from attributes and characteristics that have a major impact on product shape, function, performance, useful life, and manufacturability.

Configuration management

THK employs configuration management planning, configuration identification, change management, configuration status reports, and configuration audits to ascertain and document the achievement of given product configurations (physical and functional requirements listed on product specification sheets, drawings, component lists, and elsewhere).

Purchasing management

THK verifies supplier capabilities to ensure that we are able to purchase components that conform to our purchasing requirements. We produce documents that specify our required technical specifications and clearly communicate required control items for our suppliers, and we also confirm that our product quality and management requirements are being met.

Special process management

Special processes such as welding, heat treating, and plating cannot be validated through post-process product inspection and testing alone. Process capability, including equipment and personnel factors, must be certified before the process is performed. At THK, we secure customer approval and ensure product quality by assigning certified personnel to perform each process and constantly monitoring and managing the parameters of that process.

Securing traceability

THK ensures traceability across its entire supply chain through product identification, tracking, and records management in order to ensure product safety and quality and to respond quickly when problems occur. Our ability to track our products through each stage of the manufacturing process in this way makes it possible for us to ensure safety and quality.

Training and drills

THK conducts planned training and drills to help employees obtain the skills they need to enhance product quality. Doing so elevates the level of skill and quality awareness among our employees, which allows us to achieve better quality company-wide.

Continual improvement

THK makes use of the PDCA cycle to improve the quality of our products and both the quality and safety of our processes. We set goals for our manufacturing processes, identify points for improvement by analyzing current circumstances as we evaluate progress toward those goals, and implement corrective and preventive measures accordingly. This allows us to promote quality improvement across our organization.

Through these initiatives, THK strives to increase customer satisfaction by developing ever safer, more reliable products for the aviation industry.

THK Product Applications

As a company focused on creation and development, THK has, to this point, developed machine components and compound modular units for the machine tool, semiconductor manufacturing equipment, and general industrial machinery markets. In order to grow our business further, we have also expanded our product lineup to break into new markets like logistics, automotive and transportation equipment, medical equipment, EVs, and renewable energy. This has taken us into the aviation sector as well, where we continue to leverage our unique strengths to offer optimal solutions.

Ball splines for aircraft controls

Our compact, low-sliding resistance rotary ball splines help make aircraft controls lighter and contribute to enhanced maneuverability.

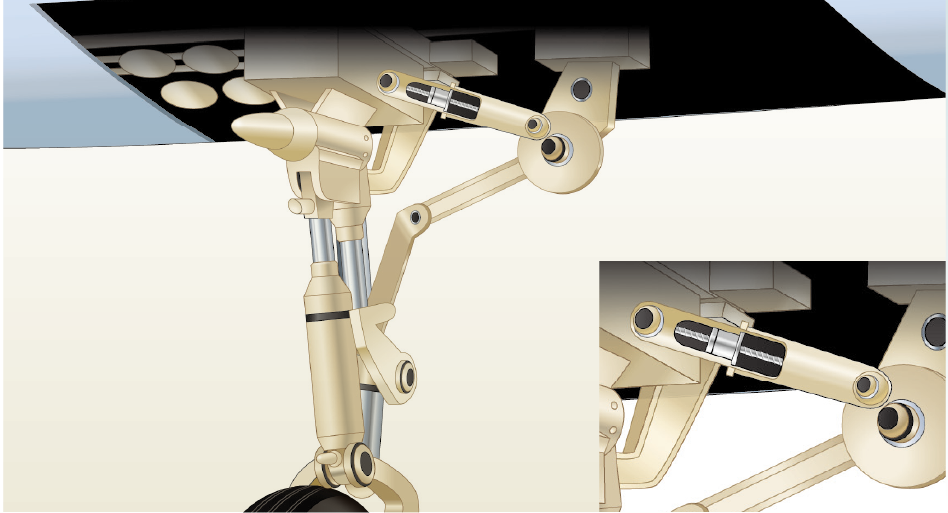

Ball screws for landing gear actuators

THK offers high-quality, highly reliable compact ball screws for aircraft landing gear.

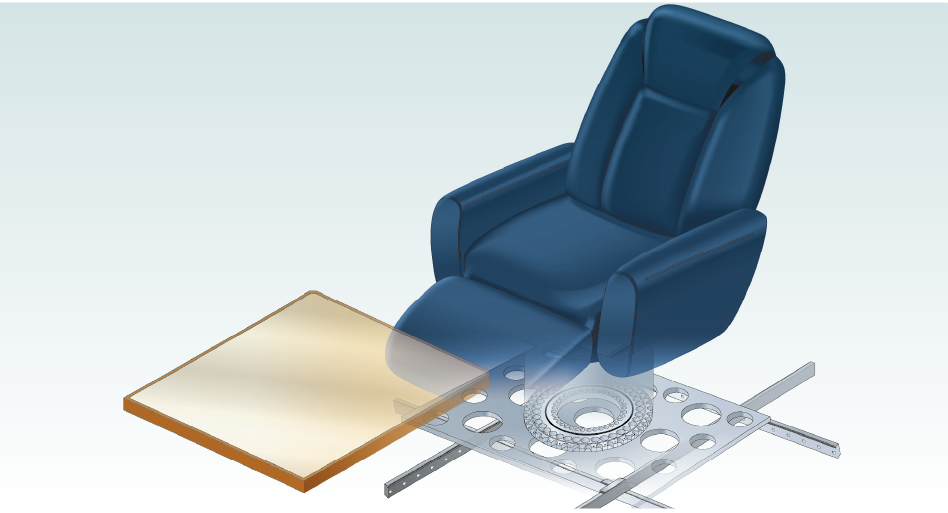

LM Guide units for airplane seat sliders and aluminum slewing bearings for seat swivel assemblies

Miniature LM Guide units are used for seat sliders. For seat swivel assemblies, THK also provides lightweight aluminum slewing bearings that use resin balls.

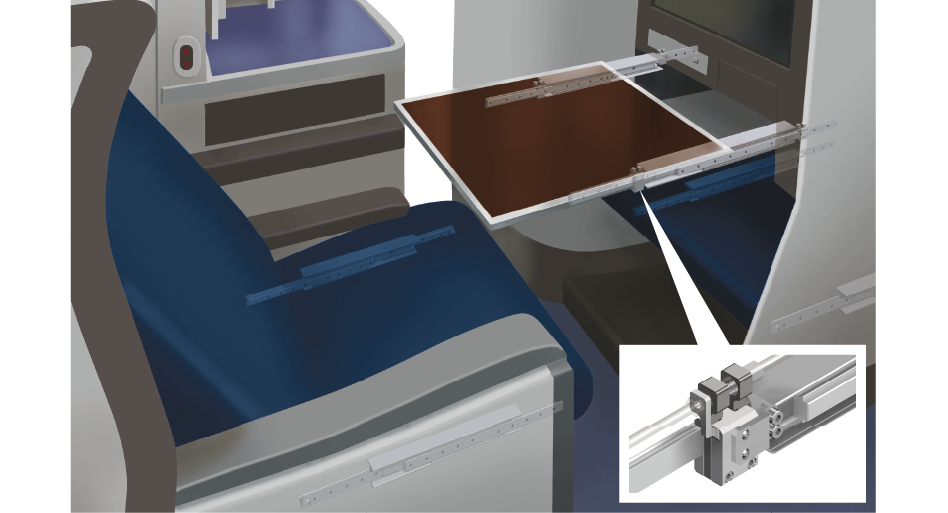

Finite double slide guides for airplane tray tables and clamps for position retention

High-strength, high-rigidity finite stroke double slide guides are used for the tray tables in business class and first class on passenger planes. A number of built-in clamps (braking units) allow passengers to lock their tray tables into positions of their choosing.

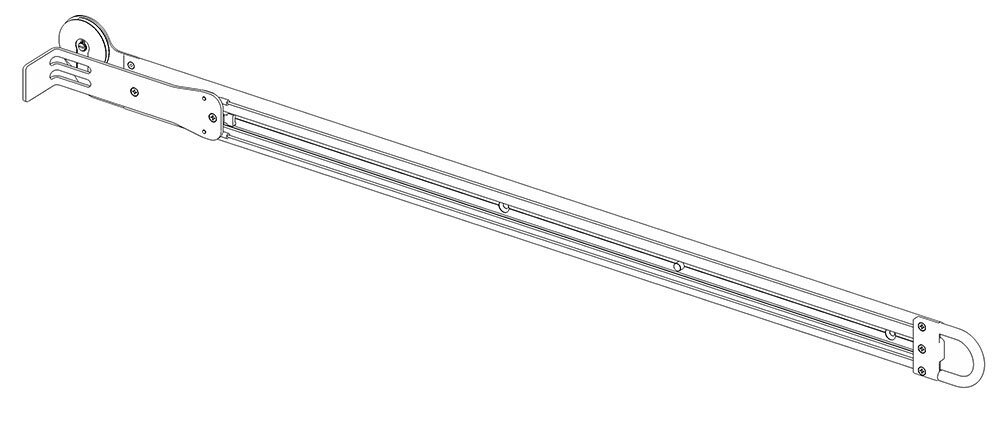

Slide units for aircraft galley container retrieval systems

Lightweight, highly reliable, aluminum sliders designed for retrieving difficult-to-reach inner containers are used for double container galleys.

A wide range of THK components are used in aircraft, for everything from seat mechanisms to the airframe itself. Going forward, we will continue to develop and provide products and services to improve aircraft fuel efficiency, reduce CO2 emissions, and address other challenges faced by our customers.

Future Outlook for the Aviation Sector

The aviation industry is expected to undergo a tremendous evolution in the future. EVTOLs (electric vertical take-off and landing aircraft) are becoming increasingly practical for various applications such as inter-city travel, logistics, and emergency transportation, which has garnered them attention as a quiet, environmentally friendly mode of transport. Cabin equipment in passenger planes is evolving to provide greater comfort and privacy, and business class seats are expected to be upgraded with more partitioning and smart cabin technology. Beyond this, growing demand for aviation in emerging countries is predicted to spur increasing demand for new aircraft equipment suited to LCCs (low-cost carriers) in particular. In the midst of it all, THK will continue to drive customer satisfaction by proposing solutions optimized for market trends and demand.

* To access the catalog, you must have a free THK Online Services account.

* This content is based on information that was released in Japanese on April 30, 2025.