Jul 2, 2025

products

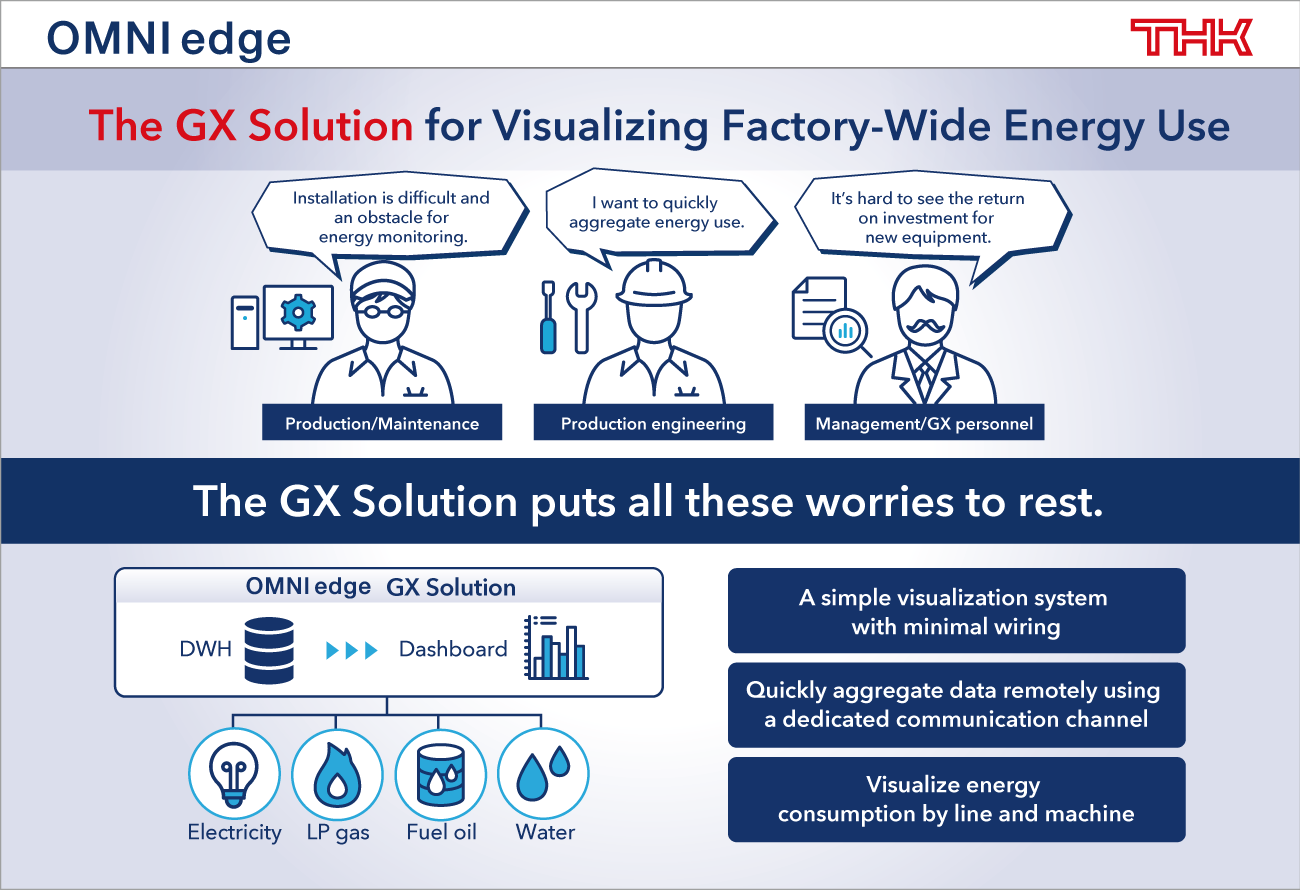

Announcing a GX Solution for the OMNIedge Platform: See Factory-Wide and Machine-Specific Energy Use at a Glance

On July 2, 2025, THK CO., LTD (Location: Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) officially released the new GX Solution for its OEE Optimization System OMNIedge.

Optimizing OEE with Expanded Solutions for Reducing Energy Loss

Up to this point, OMNIedge has been developed as a set of solutions focused on preventing loss on the machine side of things. These include the Predictive Failure Detection AI Solution for linear components and rotary components, which utilizes IoT technology, and the Tool Monitoring AI Solution for cutting tools used in machine tools. It has also been used to provide services centered on the human element as well, such as the Skill Management AI Solution for centrally managing and visualizing employee skill information on the cloud and the Integrated Maintenance Management System for optimizing maintenance activities. In addition to reducing machine- and personnel-related losses, however, factory energy management is also crucial for optimizing OEE.

At present, various industries are redoubling their efforts to achieve carbon neutrality, and the reduction of greenhouse gas emissions is seen as crucial to that aim. For the manufacturing industry, though, collecting and analyzing energy consumption data at the level of individual processes and machines is complicated by the frequency with which production lines change due to factory reorganization and the demands of variable-mix, variable-volume manufacturing.

Pairing Products with Know-How from Projects at THK’s Own Factories

Despite being very quick to set up, our GX Solution supports visualization of factory-wide energy consumption (electrical, water, gas, etc.) at the level of individual processes and machines. It also contributes to strategic energy management by identifying where waste is preventing energy savings based on know-how obtained from THK’s ongoing efforts towards carbon neutrality at its own factories.

Continuing to Provide New Solutions

By aggregating and visualizing energy consumption data from factories and data obtained from OMNIedge services in concert with generative AI, we at THK will continue to provide solutions for further productivity gains.

Features

- Easy set-up

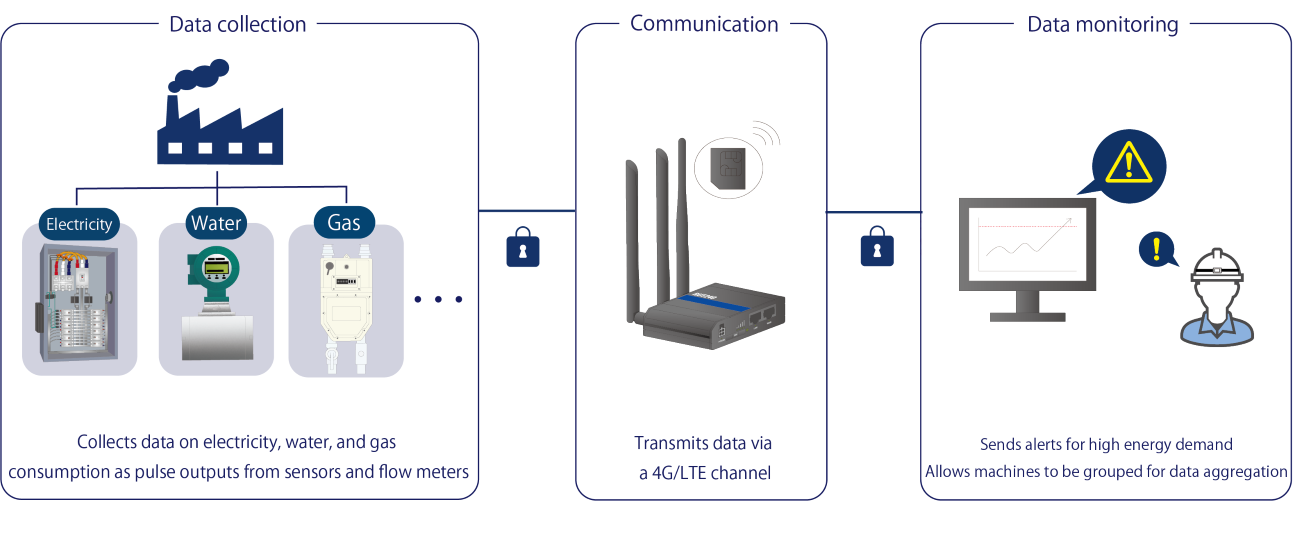

Power sensors are daisy-chained together to minimize wiring and take up less space so they can fit inside narrow distribution boards. Dedicated communication channels make it possible to quickly aggregate energy consumption remotely.

- Visualizing energy consumption by line and machine

The sensor grouping feature makes it possible to calculate energy consumption rates by line and machine in addition to factory-wide energy consumption. This solution contributes to the generation of more effective energy saving initiatives by accurately measuring the return on investment and environmental impact of equipment moves and the installation of more energy-efficient machines.

- See demand (maximum energy demand) in real time

Avoid excessive energy demand by setting thresholds in advance. If energy demand is going to exceed a threshold, a message will be displayed on the application screen.

OEE Optimization System OMNIedge

OMNIedge is a system for reducing loss that occurs on the manufacturing floor and maximizing overall equipment effectiveness (OEE).

Note) This information was originally released in Japanese on July 2, 2025.

Contact information

Please direct any product inquiries to:

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Department, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail: thk-sp@thk.co.jp