Mar 6, 2024

products

Now Accepting Orders for Precision Ball Screw with Finished Shaft Ends SDA-VZ: Enabling Smaller Devices with a Compact Nut Outer Diameter

THK CO., LTD. (Location: Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) is now accepting orders for the Precision Ball Screw with Finished Shaft Ends SDA-VZ.

The Model SDA-VZ is a precision ball screw with a screw shaft that has its end shape standardized to fit the corresponding support unit. The shaft end is pre-machined, enabling fast delivery. In addition, it achieves high speeds, possesses a compact shape, and is available in an extensive lineup of a total of 151 model types (with a screw shaft diameter of ⌀10 to ⌀25) to address varied requirements from customers.

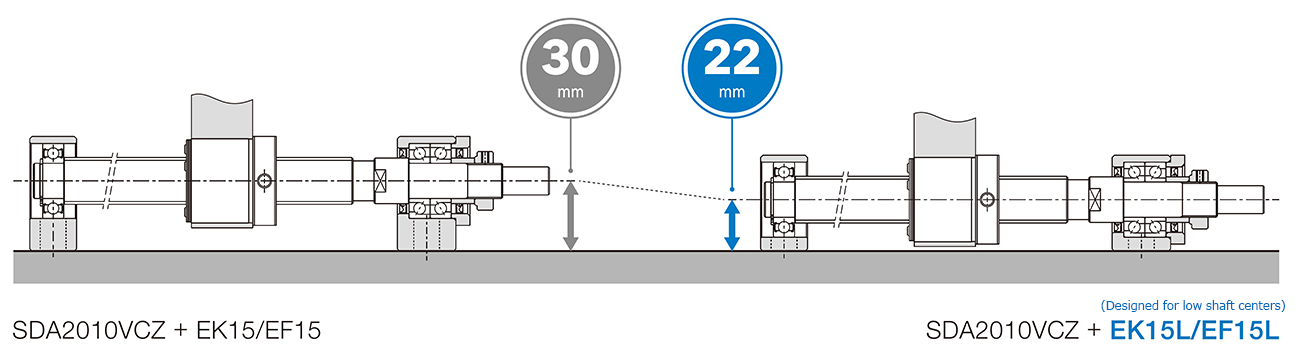

At the same time, the Model EK-L/EF-L support unit, which enables an even lower shaft center for the ball screw compared to previous support units, has been newly added to the lineup. Combining it with the Model SDA-VZ makes design of the assembly area easy and enables a drastic reduction in design hours. It contributes to space-saving for automated equipment in numerous industries, from semiconductor manufacturing equipment to all kinds of transfer equipment.

THK will continue to contribute to the performance of a wide range of equipment, from general industrial machinery to precision machinery and high-precision machine tools.

Features

Can be used at high speeds with stable torque

Picking the balls up in the tangential direction enables high-speed rotation at a maximum speed of 5,000 min-1 (DN value: 100,000) and produces stable torque even when running at high speeds for long periods of time.

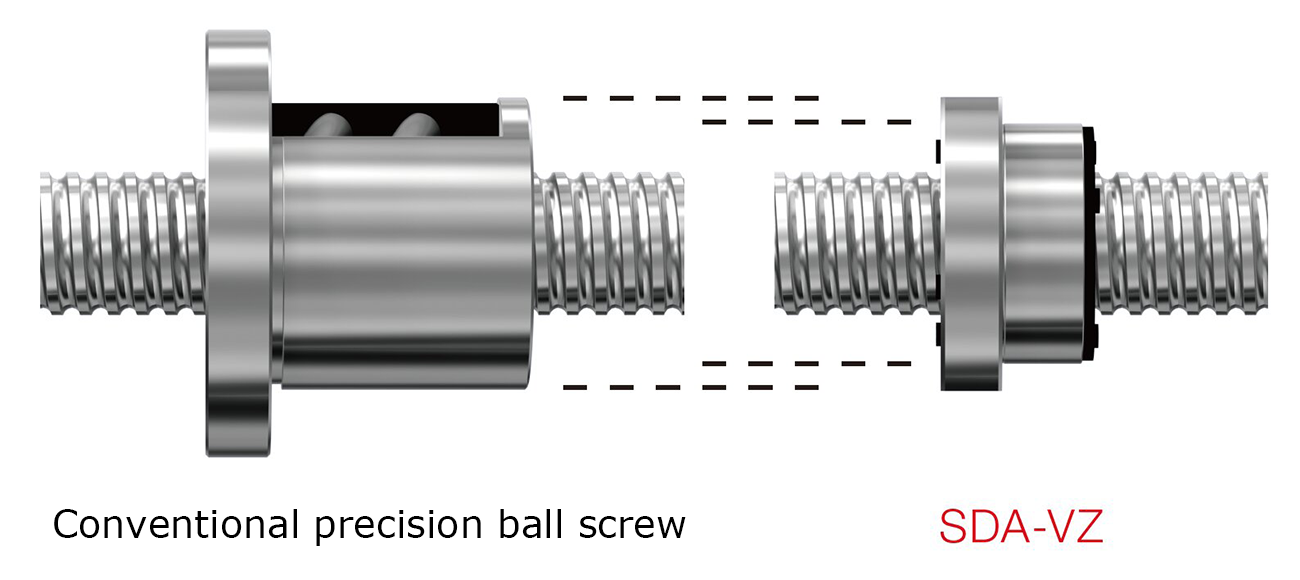

Compact shape optimal for space-saving designs

The compact design contributes to decreased equipment size due to a maximum outer diameter size reduction of 30% compared to conventional precision ball screws.

Compatible with support units for low shaft centers

The structure enables a lower shaft center than conventional support units. Using support units for low shaft centers doesn’t merely keep overall equipment size down—it also allows for more compact LM Guide configurations and reduces the amount of machining required for the mounting (base).

Related information

Please create a free account to our THK Online Servises to download catalogs. Create a free account

Note) This information was originally released in Japanese on March 6, 2024.

Contact information

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Unit, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail:thk-sp@thk.co.jp