Dec 7, 2022

products

Lineup Expanded with High-Performance, Non-magnetic, and Extremely Corrosion-Resistant Products for Special Environments That Simultaneously Achieve the Required Performance of Linear and Rotary Motion Guides, Non-Magnetic Properties, and Superior Corrosion Resistance

THK CO., LTD. (President and CEO: Akihiro Teramachi, referred to as THK below) has expanded its lineup with high-performance, non-magnetic, and extremely corrosion resistant products that provide linear and rotary motion guide performance in special environments with strong magnetic fields and corrosive chemicals that rivals performance in standard environments.

These high-performance, non-magnetic, and extremely corrosion resistant linear and rotary motion guides are composed of the special alloy THK-NM1, which has superior non-magnetic properties that make it almost completely resistant to magnetization, as well as high hardness suited to use in bearings. This alloy makes it possible to create non-magnetic products with superior load capacities that are nearly equivalent to those of existing linear and rotary motion guides. Moreover, it demonstrates extremely high corrosion resistance even in environments with corrosive chemicals.

Semiconductor manufacturing involves many processes in special environments. Some of these, such as electron beam lithography systems that draw extremely minute circuit patterns and photolithography processes that use photoresists, occupy a technological field extremely averse to magnetism that also requires the utmost corrosion resistance against special chemicals.

Products that feature non-magnetic properties and corrosion resistance have been widely used for the special environments of cutting-edge technology. In recent years, however, operational performance in environments with strong magnetic fields and corrosive chemicals has increasingly been stringently tested and evaluated against performance in standard environments, and there have been strong calls from the semiconductor manufacturing industry and others for niche general-purpose products that bring together non-magnetic properties, high precision, and high corrosion resistance. With that being the case, THK started developing this new product to satisfy the needs of customers.

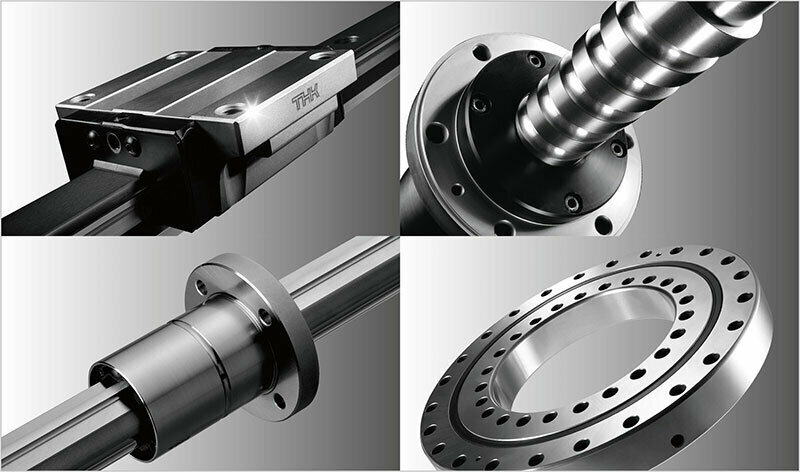

THK began by increasing its lineup with high-performance, non-magnetic, and extremely corrosion-resistant versions of its representative products, the LM Guide, ball screws, ball splines, and cross-roller rings, thereby achieving the non-magnetic properties, high precision, and high corrosion resistance that were previously challenging to achieve. In particular, using the special alloy THK-NM1 creates an ideal amount of elastic deformation on ball contact surfaces compared to general hard ceramic materials, which makes it possible to apply a preload. Additionally, of all special materials appropriate for use in bearings, this alloy resists magnetism and enables smooth motion without any clearance. The excellent resistance these products have to corrosive chemicals and their ability to achieve highly precise operations support the rapid advancement of technology recently seen in the semiconductor manufacturing industry.

With unflagging technological aptitude, THK contributes to the ongoing technological revolution by proposing high-speed, high-precision products with smaller footprints and longer service lives to the semiconductor manufacturing industry leading the way into next-generation technologies.

Features

Superior non-magnetic properties

With a relative permeability of less than 1.005, THK-NM1 offers superior non-magnetic properties that make it almost completely resistant to magnetization and is optimal for use in strong magnetic fields or in devices that control charged particles.

Excellent load capacity

Possessing the hardness required for use in bearings, THK-NM1 represents a vast improvement in load capacity compared to conventional special materials like stainless steel, non-magnetic austenitic steel, titanium, and ceramic.

Smooth, highly precise motion

THK-NM1 gives linear and rotary motion guides sufficient elasticity to allow for the application of a preload, enabling smooth motion without clearance.

Extremely high corrosion resistance

With its extremely high corrosion resistance, THK-NM1 helps to maintain equipment function even in environments with highly corrosive chemicals.

Related information

Please create a free account to our THK Online Servises to download catalogs. Create a free account

Note) This information was originally released in Japanese on December 7, 2022.

Contact information

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Unit, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail:thk-sp@thk.co.jp