Mar 10, 2021

products

THK’s “OMNIedge” IoT Service for the Manufacturing Industry Now Available for Actuators in Addition to the LM Guide and Ball Screws

As of March 2021, THK CO., LTD. (Location: Minato, Tokyo; CEO: Akihiro Teramachi; hereinafter referred to as “THK”) has expanded the lineup for its “OMNIedge” IoT service for the manufacturing industry, which launched last year. In addition to LM Guide and ball screw applications, the service is now also available for actuators, which are widely used in manufacturing operations.Interest in OMNIedge has grown over time, and over 1,000 units are already in use for devices at customer sites and THK’s own facilities. Many users of OMNIedge have expressed their praise and expectations for the system’s ability to visualize the status of components and to collect and analyze numerical data in a simple way.

Because of their user-friendliness, actuators (LM Guide Actuator KR/SKR Series products) have been widely adopted for use alongside the LM Guide and ball screws in automated devices such as transfer and assembly equipment. For the components of such devices, the need for predictive failure detection has expanded beyond the LM Guide and ball screws to also include actuators. In order to respond to that demand, THK has begun offering long-awaited actuator compatibility for the service.

While the company is currently in the middle of conducting a free trial to broaden the range of applications to include rotary components in devices such as pumps and fans, THK will continue to expand the service to further the management of overall equipment health with predictive failure detection for machine components at its core.

Through this service, THK will contribute to continuous improvements in productivity on the manufacturing floor.

Features

Visualizes Actuator Conditions

OMNIedge quantifies and visualizes condition data collected by attaching a sensor with THK’s proprietary THK SENSING SYSTEM technology to an actuator. This allows the system to quantify the damage and lubrication status of the actuator and detect its condition.

No Modifications or Additional Machining Required to Install the Sensor

Just like with the current LM Guide and ball screw versions, installation is easy. The sensor only needs to be attached to the outside of the main actuator unit. No modifications or additional machining is required—OMNIedge can even be added to a device in operation. This is perfect for customers who want to get started with predictive failure detection right away.

An LM Guide, Ball Screw, and Actuator Sensor Can All Connect to a Single Amplifier

A single amplifier can have up to three sensors connected at a time. Any combination of connected components (including LM Guide units, ball screws, and actuators) can be connected to the same amplifier to suit the configuration of machine elements inside equipment.

In addition to machine tools, the system can be used for general industrial machinery, such as transfer and assembly devices, which have widely adopted the use of actuators.

Same as the LM Guide and ball screw versions, the actuator version is available at the low monthly cost of 8,000 yen/device.

OMNIedge: An IoT Service for the Manufacturing Industry

Service Overview

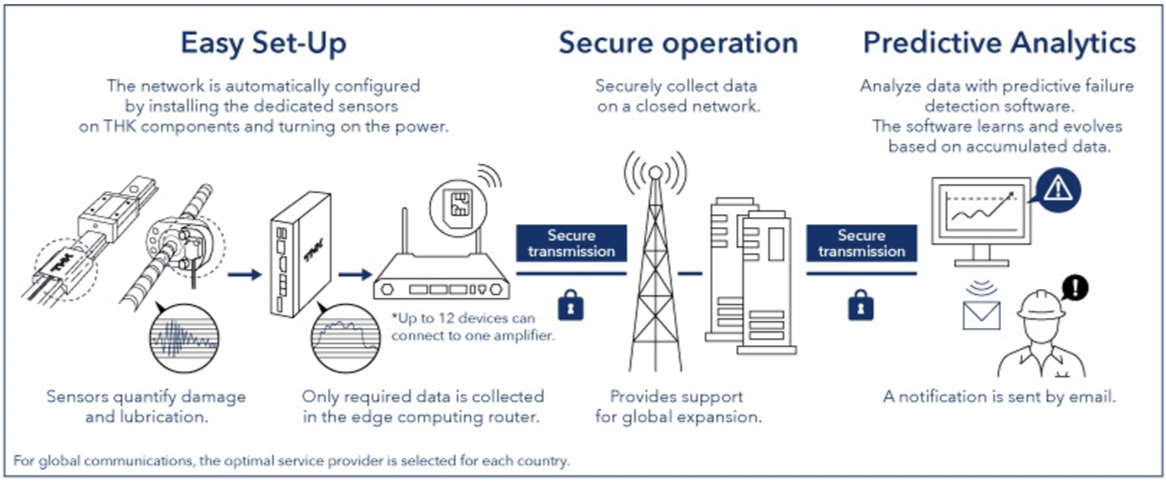

OMNIedge is a system that diagnoses the status of a machine component and performs predictive failure detection. Using the THK SENSING SYSTEM, a sensor attached to the component collects data, which is then quantified and analyzed by an original algorithm and transmitted through a secure network. The package comes with a sensor, amplifier, and communication device, and communication fees are included, which means the service is simple and secure, with zero initial costs.

Usage Fee

Starts at 8,000 yen/month for 1 device (with a 2-year contract)

Orders Open/Shipping Begins

Orders open as of March 10, 2021. Shipping begins as of April 9, 2021.

OMNIedge Connection Configuration

| Contents are subject to change without notice for the purpose of improvement. OMNIedge is a registered trademark of THK CO., LTD. |

OMNIedge Website

Note) This information was originally released in Japanese on March 10, 2021.