Sep 10, 2025

products

Orders Open for Multi-Suction Hand for Complex Shapes: Increased Load Capacity for Expanded Use in the Automotive Industry

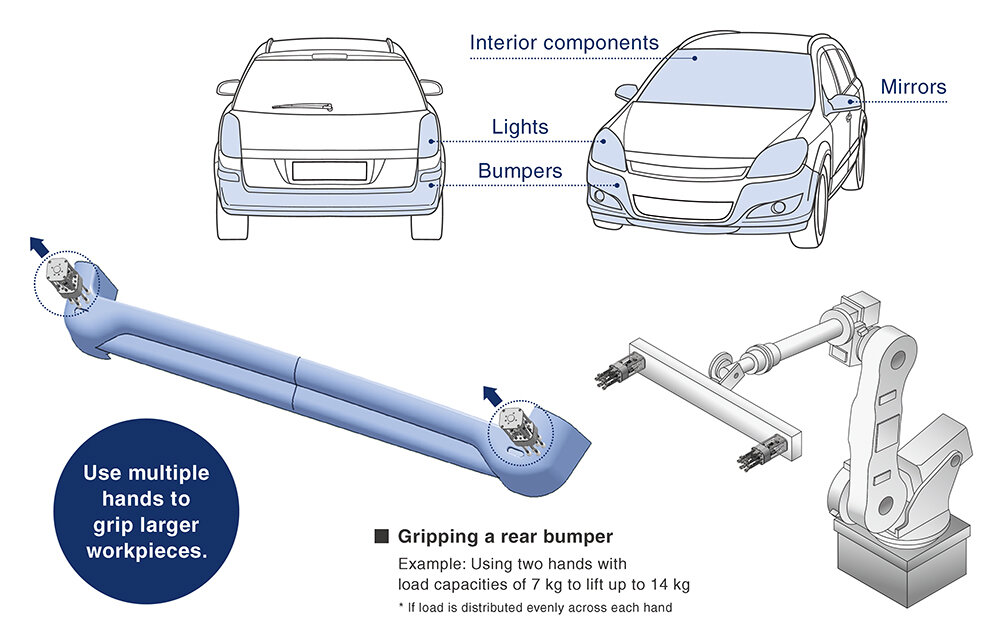

THK CO., LTD. (Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) is now accepting orders for Multi-Suction Hand TNH08-V09. Intended for the automotive component industry, this product is ideal for gripping workpieces with complex shapes.

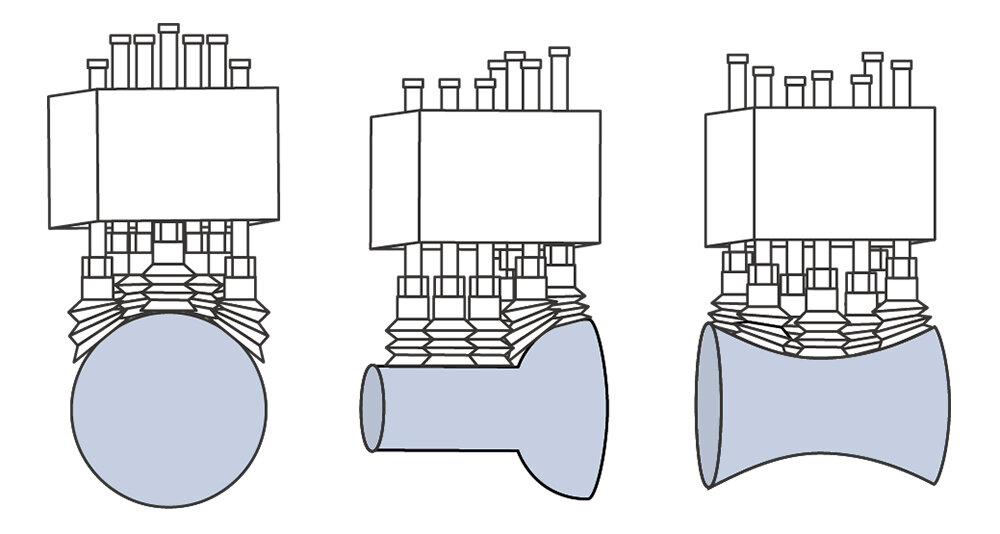

Multi-Suction Hand is a robot hand designed to reduce changeover time, a major challenge for variable-mix, variable-volume manufacturing. This modular hand comprises nine hollow shafts with suction cups at their tips that conform to the shape of a workpiece while exerting suction to grip it.

A single hand has a load capacity of 7 kg, so multiple hands used together can even lift automotive components like bumpers, headlights, and the like. Built-in sensors make workpiece detection and suction status monitoring possible as well.

In recent years, the rising popularity of next-generation vehicles has driven more exacting requirements for variable-mix, variable-volume manufacturing and more refined design in the realm of automotive parts. The challenge with running a variety of parts with complex shapes on a production line, though, is the need to shorten how long it takes to change from one robot hand to another.

Using THK's unique quick clamper element technology, Multi-Suction Hand is able to conform to, stabilize, and transfer workpieces with complex shapes. Capable of gripping a variety of workpiece types, it contributes to shorter cycle times by eliminating the need to switch from one hand to another at all.

Through the development of new, original products, THK will continue to meet the automation and labor-saving needs of all industries, proposing solutions that will boost productivity and improve processes.

Features

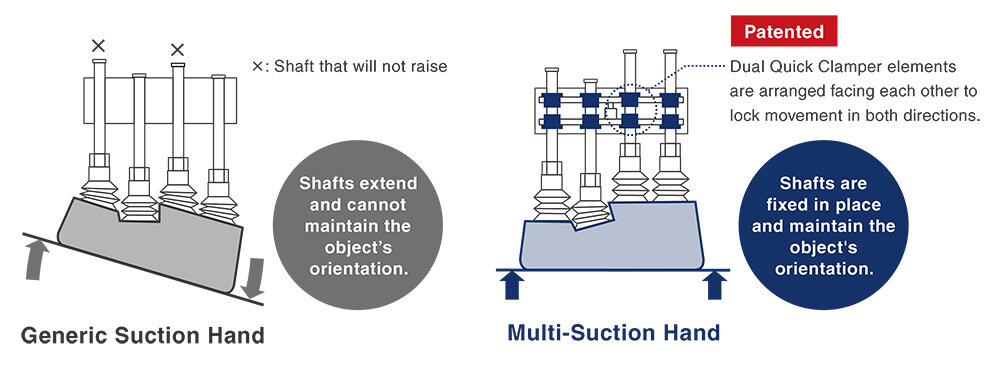

・Conforms to complex shapes: Shafts become fixed to maintain workpiece orientation

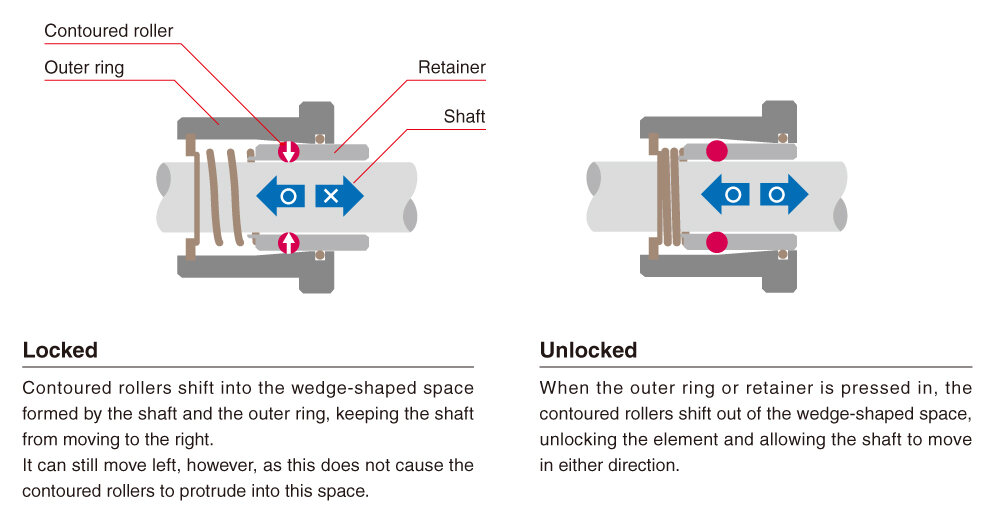

Grips workpieces in a secure orientation using THK’s unique, patented Quick Clamper element* technology.

* A machine component with a locking mechanism that lets you clamp and unclamp an object moving linearly with one touch. It consists of an outer ring with built-in contoured roller bearings.

・No changeovers required: One hand for a variety of workpieces

The nine shafts conform to various shapes, eliminating the need to switch hands and contributing to reduced changeover loss.

・Simplified equipment design: A modular structure for reduced design time

A compact, lightweight structure made possible by patented technology.

Note) This information was originally released in Japanese on September 10, 2025.

Contact information

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Department, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail: thk-sp@thk.co.jp