Jul 30, 2025

products

THK Yamaguchi Plant Deploys the OMNIedge GX Solution, Accelerating Efforts to Reduce Energy Loss and Achieve Carbon Neutrality

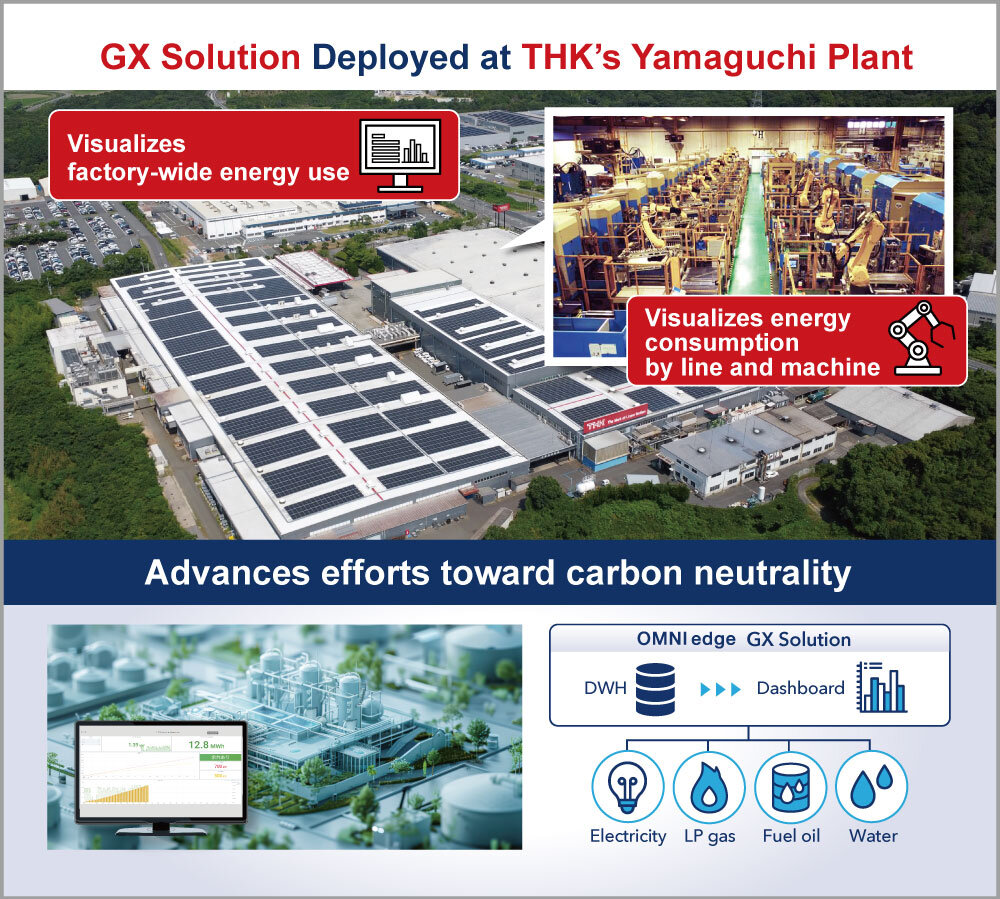

THK CO., LTD. (Location: Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) has deployed the GX Solution through our OMNIedge OEE Optimization System at our very own Yamaguchi plant (Sanyo-Onoda, Yamaguchi Prefecture). By visualizing the plant’s power consumption per machine, we are accelerating our efforts toward achieving carbon neutrality while also identifying which devices are experiencing energy loss, detecting equipment wear and tear, and predicting machine failure. Based on the know-how we have acquired through these efforts, we will provide a GX solution that solves the problem of energy loss that occurs on other production floors as well.

Promoting Carbon Neutrality at THK

In response to the global challenge of addressing the risks associated with climate change, the THK Group has established a New Carbon Neutrality Promotion Project within our production division and promoted a number of activities aimed at reducing our greenhouse gas emissions. Such activities have included introducing solar power generation and upgrading to energy-efficient equipment, but our methods for understanding the quantitative effect of these efforts were lacking. Even though our former measurement methods allowed us to see our energy consumption on a factory-wide, macro level, it was difficult to evaluate our energy efficiency on the micro level of individual machines. On top of that, the manual gathering of data on a monthly basis placed a burden on local employees.

Reducing Energy Loss by Introducing the GX Solution at THK Plants

To solve these issues, we installed the GX Solution, which enables a detailed look at energy consumption. This implementation led to the following benefits.

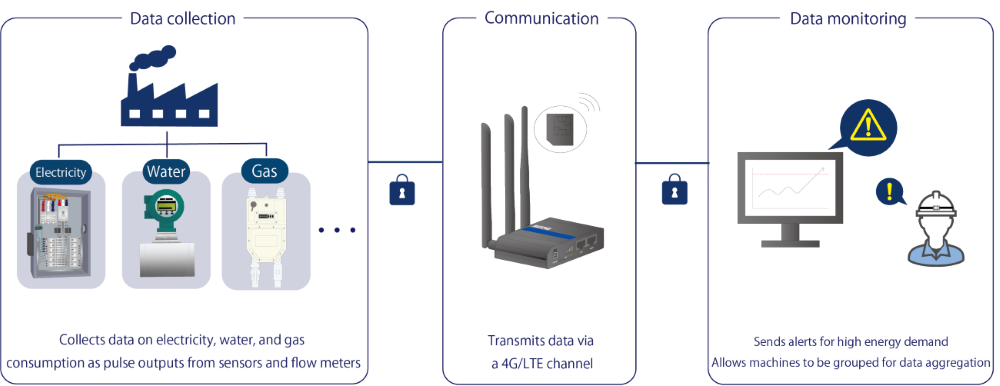

Quick aggregation of energy consumption

The energy consumption of not only the entire plant, but each device inside it, can be monitored remotely. This significantly reduced the amount of time spent gathering data.

Optimization of operating times

We were able to revise our operating times based on data gathered by the GX Solution. Minimizing the power used during idling helped reduce energy costs.

Effective capital investment

Measuring and comparing the energy consumption and air flow of each compressor helped us identify which compressors were worn down. We will use this analysis to determine which units are most in need of an upgrade when planning investments.

Proposals That Combine Products with Know-How Gained from Projects at THK’s Own Factories

By implementing the OMNIedge GX Solution, THK is striving to solve energy-related challenges in our factories while also promoting new initiatives to achieve carbon neutrality, including detecting machine errors by cross-referencing energy data with production results and developing an energy efficiency diagnostic function based on energy data. Based on the know-how we have acquired through the implementation of these efforts toward carbon neutrality, we will provide a GX solution that helps solve the issue of energy loss.

Features

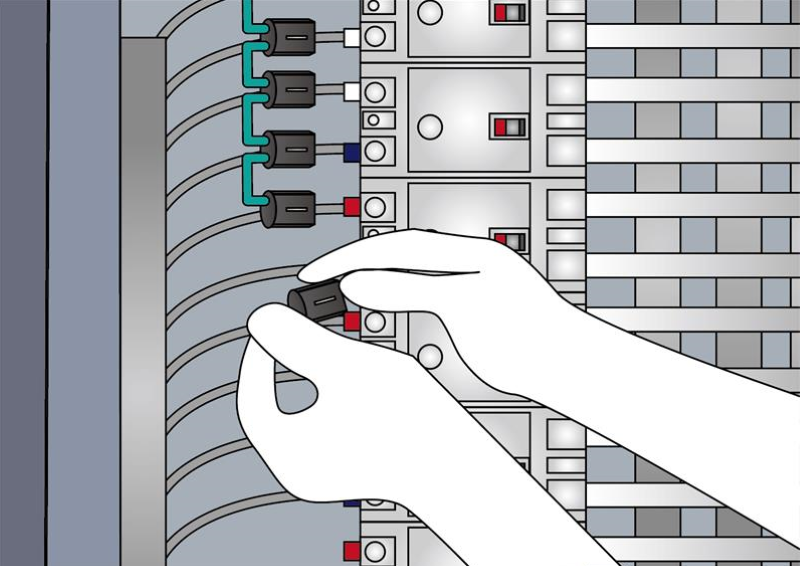

Easy set-up

Power sensors are daisy-chained together to minimize wiring and take up less space so they can fit inside narrow distribution boards. Dedicated communication channels make it possible to quickly aggregate energy consumption remotely.

Visualizing energy consumption by line and machine

The sensor grouping feature makes it possible to calculate energy consumption rates by line and machine in addition to factory-wide energy consumption. This solution contributes to the generation of more effective energy saving initiatives by accurately measuring the return on investment and environmental impact of equipment moves and the installation of more energy-efficient machines.

See demand (maximum energy demand) in real time

You can set thresholds in advance. If energy demand is going to exceed a threshold, a message will be displayed on the application screen.

OEE Optimization System OMNIedge

OMNIedge is a system for reducing loss that occurs on the manufacturing floor and maximizing overall equipment effectiveness (OEE).

Note) This information was originally released in Japanese on July 30, 2025.

Contact information

Please direct any product inquiries to:

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Department, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail: thk-sp@thk.co.jp