Precision Ball Screw/Spline

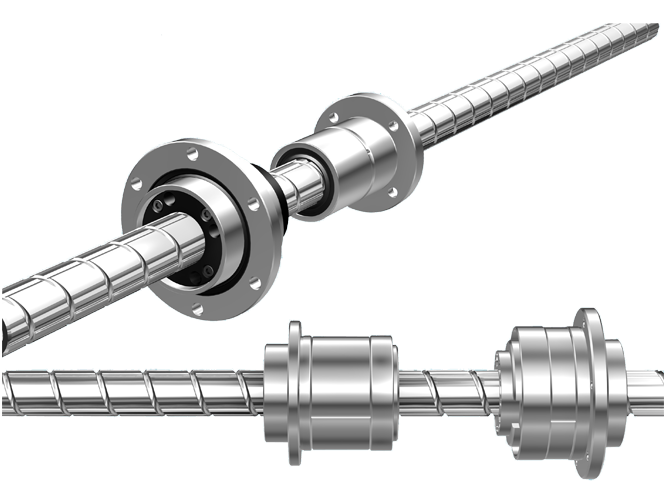

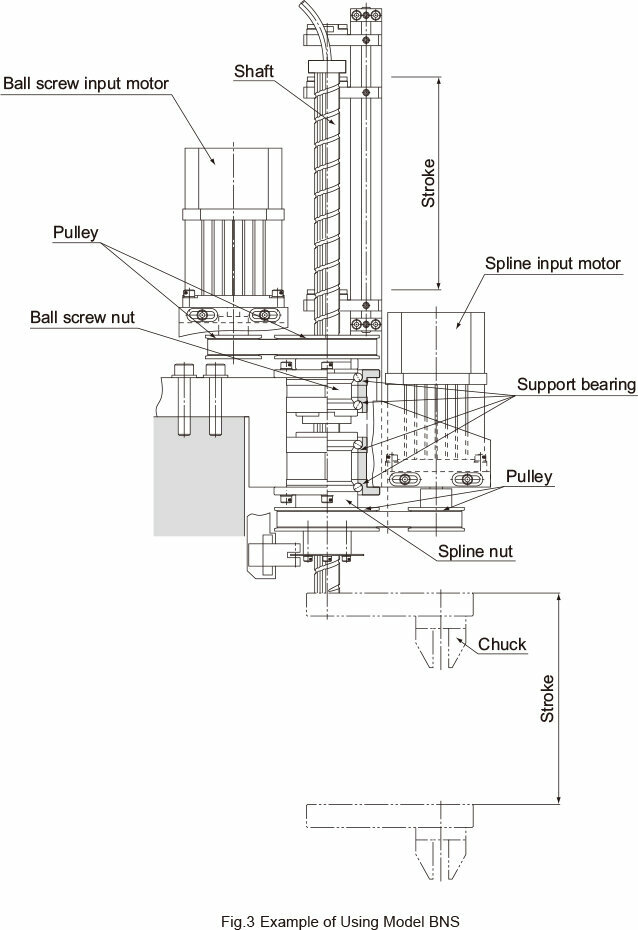

The ball screw/spline contains the ball screw grooves and the ball spline groove crossing one another. The nuts of the ball screw and the ball spline have dedicated support bearings directly embedded on the circumference of the nuts.

The ball screw/spline is capable of performing three (rotational, linear, and spiral) modes of motion with a single shaft by rotating or stopping the spline nut.

It is ideal for machines using a combination of rotary and straight motions, such as the Z axis of SCARA robots, assembly robots, automatic loaders, and machining center ATC equipment.

Types

Highlight feature tags

- Compact

- Large lead

- Preload

- No preload

- Rotary nut

- Rotary ball spline

- Precision positioning (ball screw)

- Precision positioning (ball screw)

- Large lead

- No preload

- Compact

- Rotary nut

- Rotary ball spline

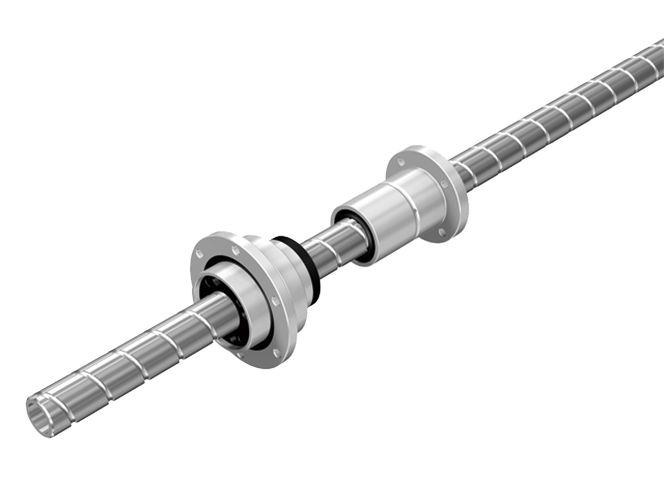

Screw shaft diameter (mm) : 16,20,25

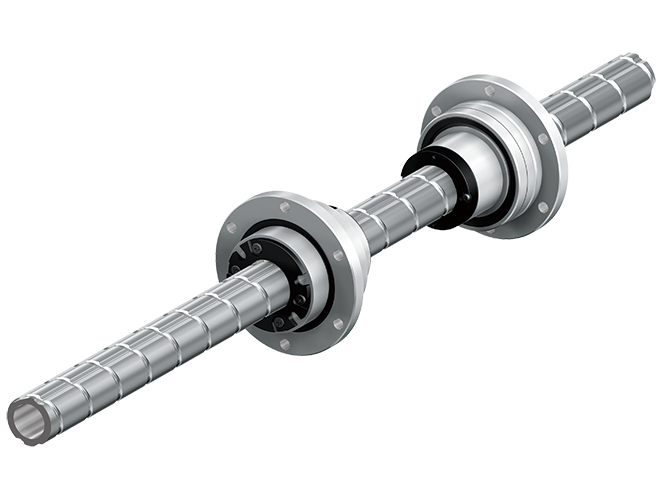

- Precision positioning (ball screw)

- Large lead

- Preload

- Rotary nut

- Rotary ball spline

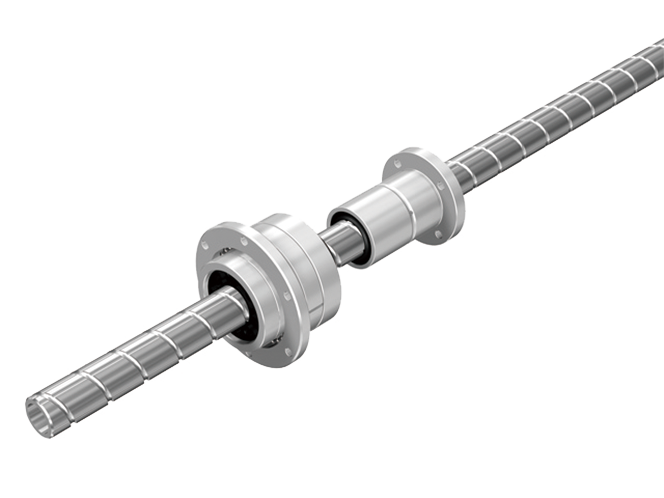

Screw shaft diameter (mm) : 08,10,16,20,25,32,40

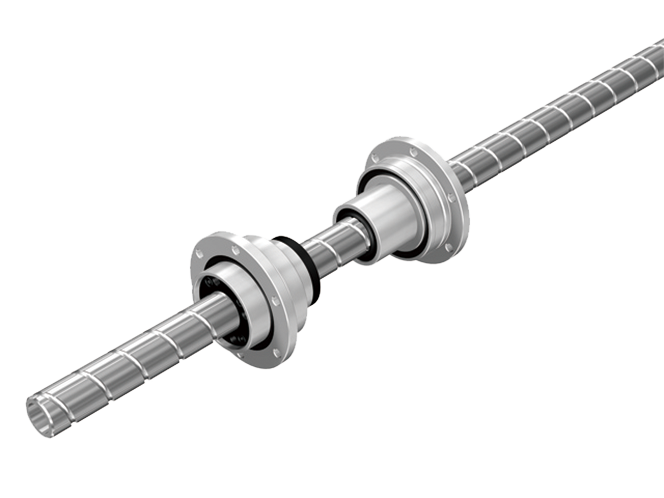

- Precision positioning (ball screw)

- Large lead

- Preload

- Rotary nut

- Rotary ball spline

Screw shaft diameter (mm) : 16,20,25,32,40,50

- Precision positioning (ball screw)

- Large lead

- No preload

- Compact

- Rotary nut

Screw shaft diameter (mm) : 16,20,25

- Precision positioning (ball screw)

- Large lead

- Preload

- Rotary nut

Screw shaft diameter (mm) : 08,10,16,20,25,32,40

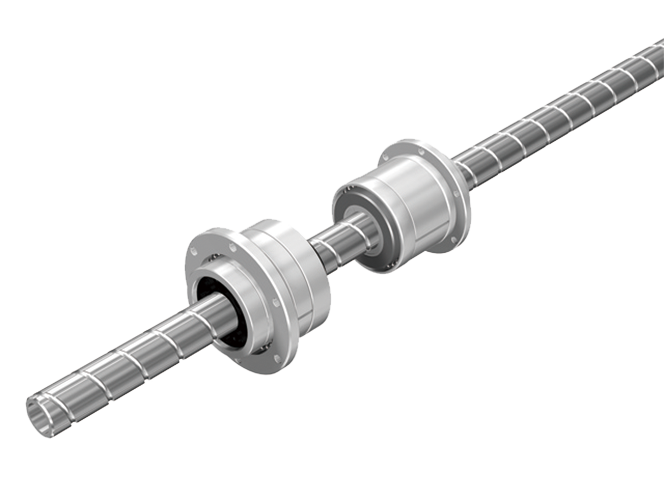

- Precision positioning (ball screw)

- Large lead

- Preload

- Rotary nut

Screw shaft diameter (mm) : 16,20,25,32,40,50

Features

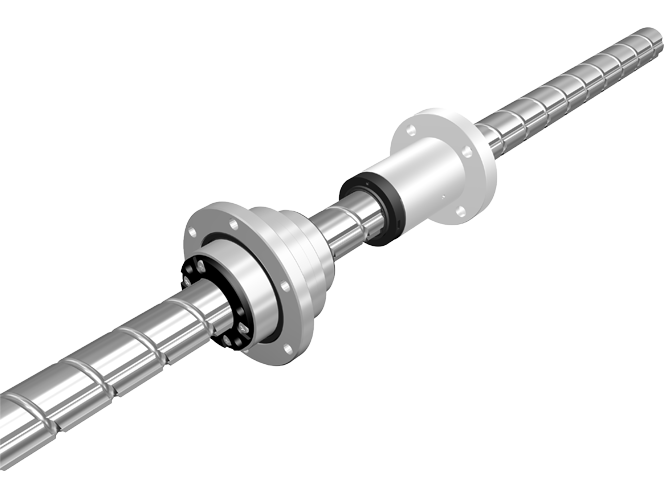

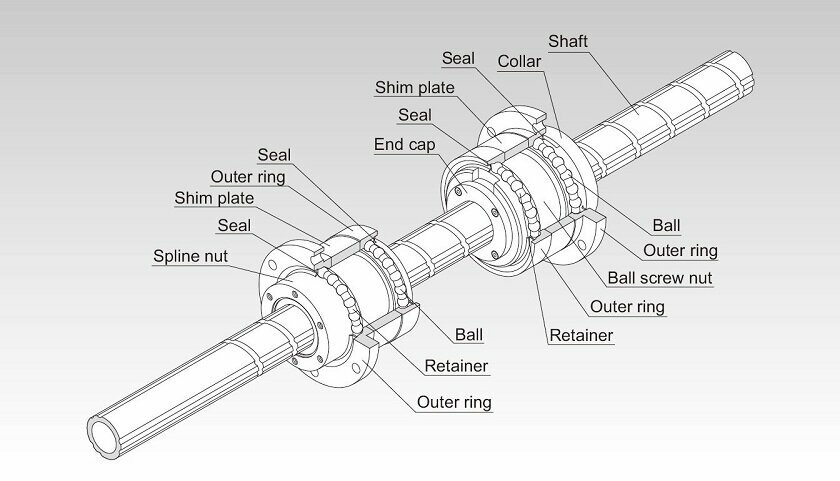

Structure and Features

The ball screw/spline contains the ball screw grooves and the ball spline groove crossing one another. The nuts of the ball screw and the ball spline have dedicated support bearings directly embedded on the circumference of the nuts.

The ball screw/spline is capable of performing three (rotational, linear, and spiral) modes of motion with a single shaft by rotating or stopping the spline nut.

It is ideal for machines using a combination of rotary and straight motion, such as the Z-axis of SCARA robot, assembly robots, automatic loaders, and machining center ATC equipment.

Zero Axial Clearance

The ball spline has an angular-contact structure that causes no backlash in the rotational direction, enabling highly accurate positioning.

Lightweight and Compact

Since the ball screw nut and the support bearing are integrated, a highly accurate and compact design is achieved. In addition, small inertia due to the lightweight ball screw nut ensures high responsiveness.

Easy Installation

The ball spline nut is designed so that balls do not fall off even if the spline nut is removed from the shaft, making installation easy. The ball screw/spline can easily be mounted simply by securing it to the housing with bolts. (For the housing’s inner-diameter tolerance, H7 is recommended.)

Smooth Motion with Low Noise

As the ball screw is based on an end cap mechanism, smooth motion with low noise is achieved.

Highly Rigid Support Bearing

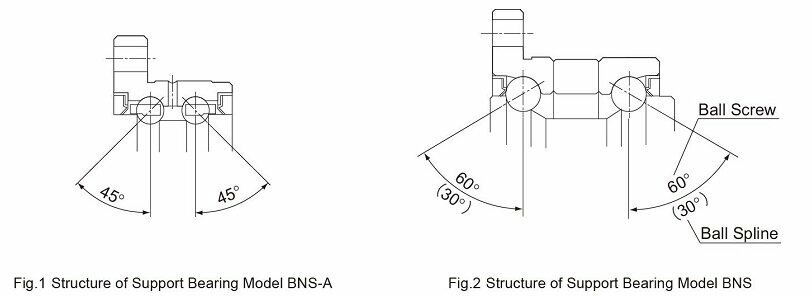

The support bearing on the Ball Screw has a contact angle of 60° in the axial direction while that on the Ball Spline has a contact angle of 30° in the moment direction, providing a highly rigid shaft support. In addition, a dedicated rubber seal is attached as standard to prevent inflow of foreign materials.

Example Applications

Precautions on Use

Lubrication

When lubricating the ball screw/spline, attach the greasing plate to the housing in advance.