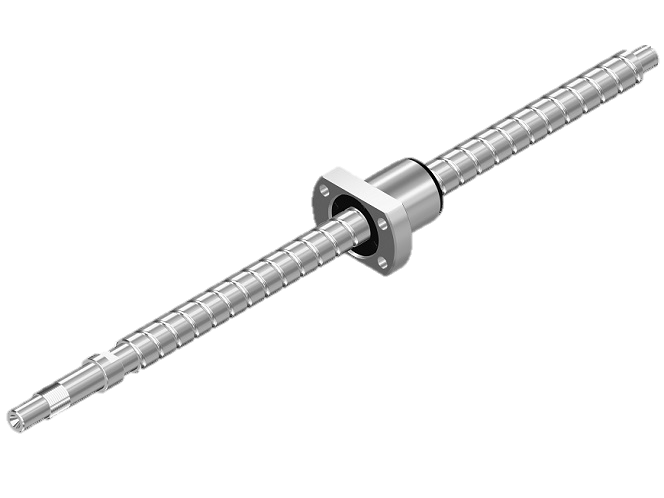

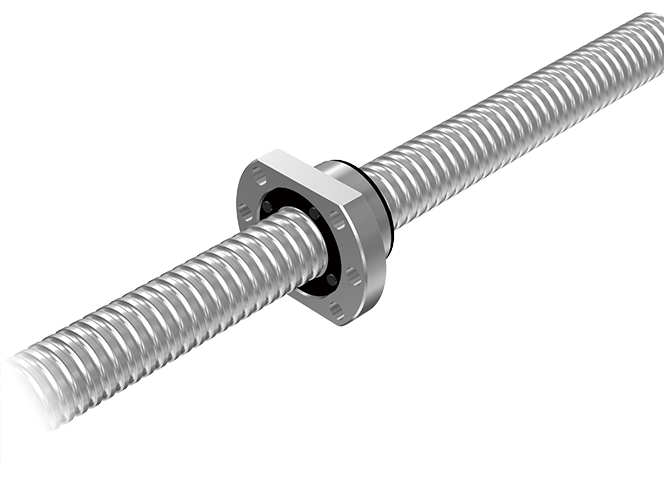

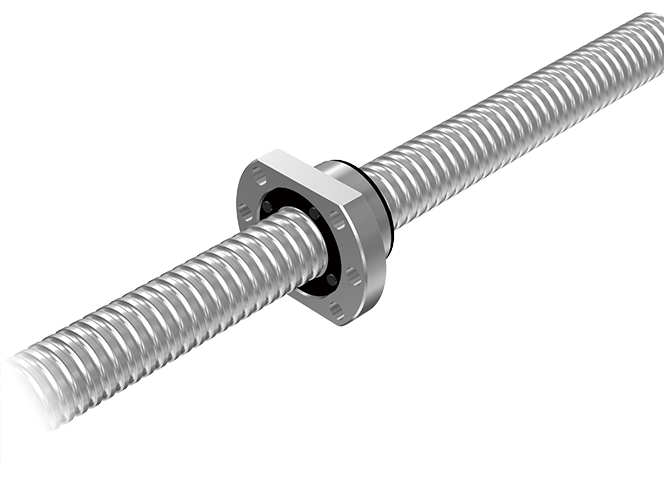

Precision Ball Screw with Finished Shaft Ends SDA-VZ

This product picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 min-1 (DN value: 100,000). Torque remains stable even during long periods of high-speed operation.

Types

Highlight feature tags

- Compact

- High speed

- Screw shaft end additional machining

- In accordance with ISO standards

- Super lead

- Large lead

- Preload

- Precision positioning (ball screw)

- Precision positioning (ball screw)

- Screw shaft end additional machining

- In accordance with ISO standards

- Preload

- High speed

- Compact

Lead(mm) : 5,10

- Precision positioning (ball screw)

- Screw shaft end additional machining

- In accordance with ISO standards

- Super lead

- Large lead

- Preload

- High speed

- Compact

Lead(mm) : 5,10,20,30

- Precision positioning (ball screw)

- Screw shaft end additional machining

- In accordance with ISO standards

- Super lead

- Large lead

- Preload

- High speed

- Compact

Lead(mm) : 5,10,20,30

- Precision positioning (ball screw)

- Screw shaft end additional machining

- In accordance with ISO standards

- Super lead

- Large lead

- Preload

- High speed

- Compact

Lead(mm) : 5,10,20,30,40,60

- Precision positioning (ball screw)

- Screw shaft end additional machining

- In accordance with ISO standards

- Super lead

- Large lead

- Preload

- High speed

- Compact

Lead(mm) : 5,10,20,25,30,50

Features

High speed

This product picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 min-1 (DN value: 100,000).

Torque remains stable even during long periods of high-speed operation.

Keeps equipment compact with space-saving design and low shaft center compatibility

This product keeps equipment designs compact by featuring an outer diameter that is up to 30% smaller than conventional THK products.

The nut dimensions conform to ISO standards (ISO 3408).*

* Excluding SDA15VCZ and 20VCZ

Lineup of support units optimized for low shaft centers

Compared to conventional support units, the design is better optimized for ball screws with lower shaft centers. Combining these support units with the Model SDA-VZ will maximize the space-saving potential.

Lineup

We meet the requirements of a wide variety of shaft diameters, leads, and strokes.

| Shaft diameter |

Lead | Stroke | Support unit | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1600 | Fixed side | Supported side | ||

| 10 | 5 | ● | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||||

| 10 | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||||||

| 12 | 5 | ● | ● | ● | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||

| 10 | ● | ● | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||||

| 20 | ● | ● | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||||

| 30 | ● | ● | ● | ● | ● | EK8L,FK8 | EF8L,FF6 | |||||||||

| 15 | 5 | ● | ● | ● | ● | ● | ● | ● | EK12L,FK12 | EF12L,FF12 | ||||||

| 10 | ● | ● | ● | ● | ● | ● | ● | ● | EK12L,FK12 | EF12L,FF12 | ||||||

| 20 | ● | ● | ● | ● | ● | ● | ● | ● | EK12L,FK12 | EF12L,FF12 | ||||||

| 30 | ● | ● | ● | ● | ● | ● | ● | ● | EK12L,FK12 | EF12L,FF12 | ||||||

| 20 | 5 | ● | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | |||||

| 10 | ● | ● | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | |||||

| 20 | ● | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | ||||||

| 30 | ● | ● | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | |||||

| 40 | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | |||||||

| 60 | ● | ● | ● | ● | ● | ● | ● | EK15L,FK15 | EF15L,FF15 | |||||||

| 25 | 5 | ● | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | |||||

| 10 | ● | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | ||||||

| 20 | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | |||||||

| 25 | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | |||||||

| 30 | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | |||||||

| 50 | ● | ● | ● | ● | ● | ● | ● | EK20,FK20 | EF20,FF20 | |||||||