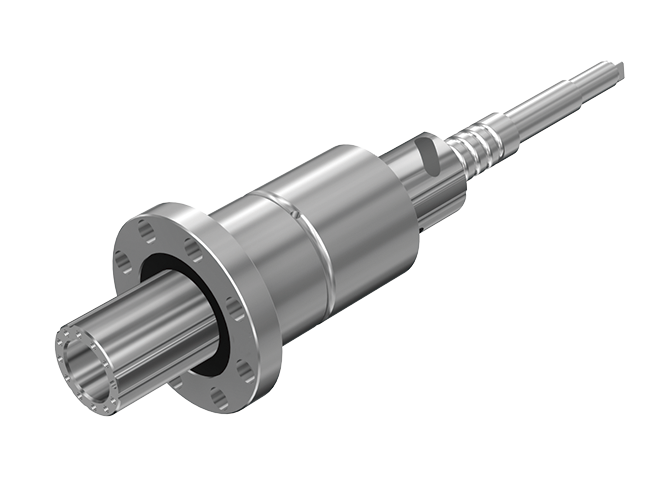

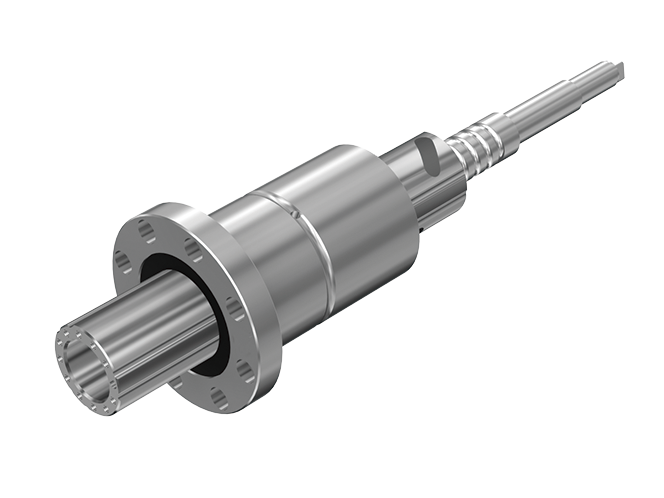

DSP Ball Spline with Integrated Ball Screw

The overall length of the DSP is compact compared to conventional products due to its unique structure, which combines the linear motion guide and drive element. As a result, incorporating the DSP in equipment allows for space savings in height and width. Also, since the number of parts is reduced compared to the general structure, the assembly time and number of machined parts is reduced, contributing to time savings in equipment design and manufacturing.

Types

Highlight feature tags

- Corrosion resistance

- For presses

- For presses

Screw shaft diameter (mm) : 16

- For presses

Screw shaft diameter (mm) : 20,25

- Corrosion resistance

Screw shaft diameter (mm) : 32

- For presses

Screw shaft diameter (mm) : 36

- For presses

Screw shaft diameter (mm) : 50

Features

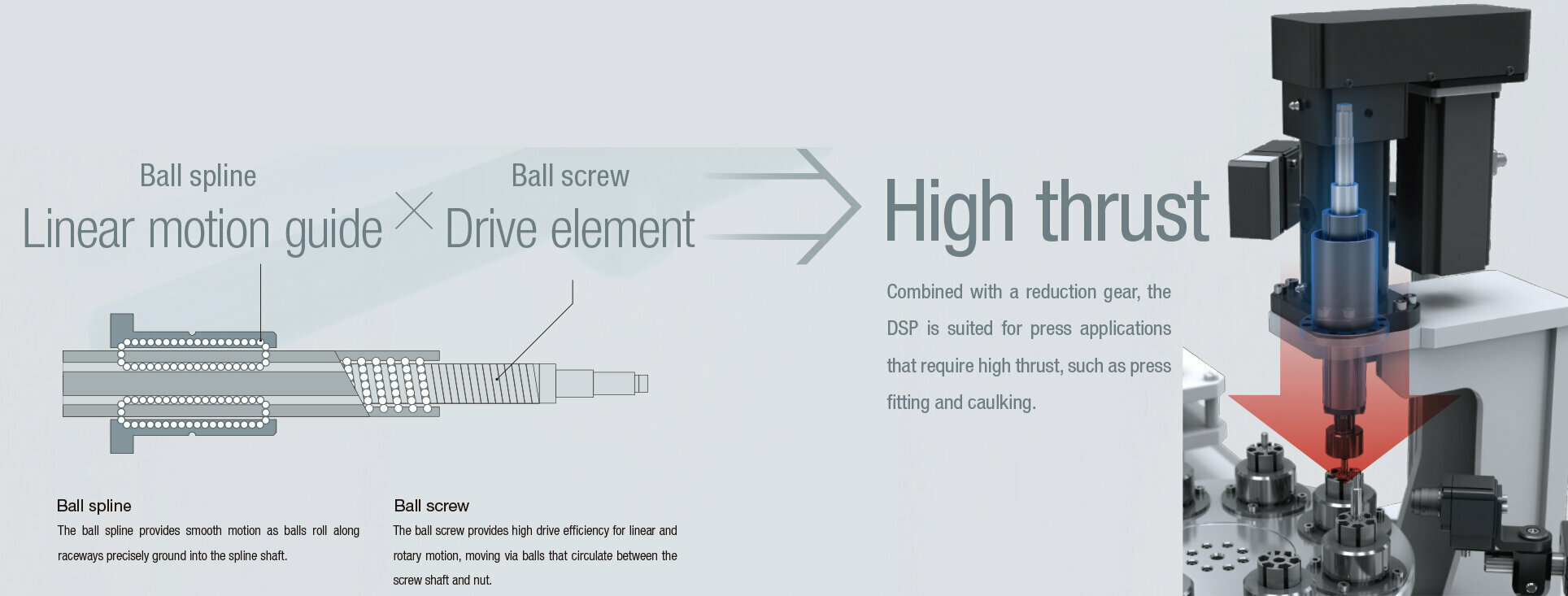

Large Thrust Transmission

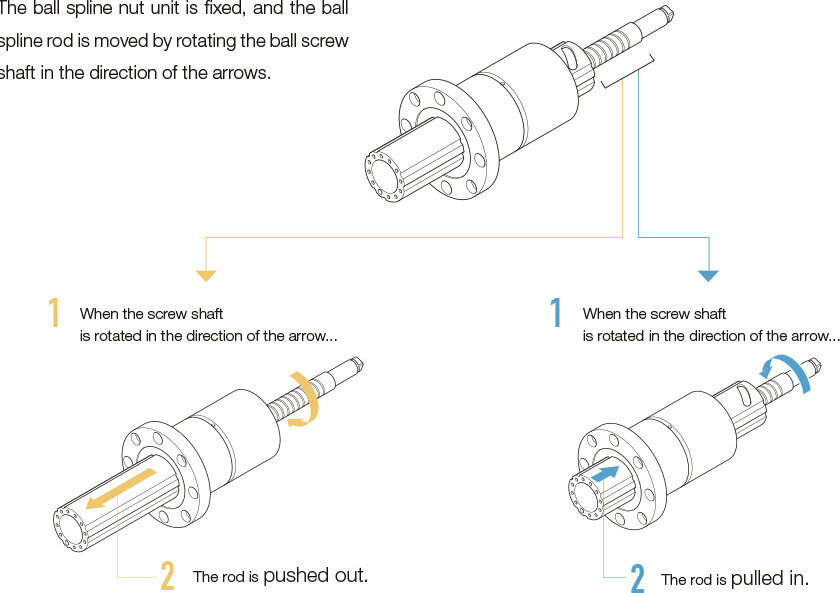

High thrust is transmitted with smooth motion by combining a ball spline, which serves as a linear motion guide, with a ball screw, which serves as the driving force.

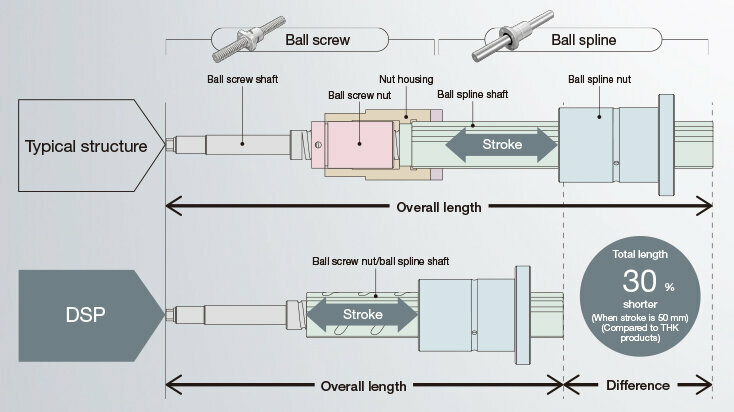

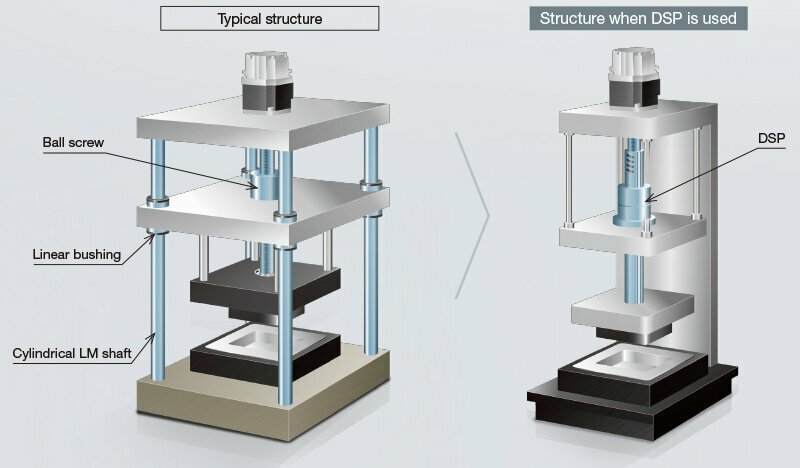

Machine requires less space due to compact structure

The overall length of the DSP is compact compared to conventional products due to its unique structure, which combines the linear motion guide and drive element. As a result, incorporating the DSP in equipment allows for space savings in height and width.

Reduces equipment design and fabrication time

The DSP has fewer components than conventional products, helping to reduce equipment design and fabrication time through a reduction in assembly time and manufactured parts.

Application examples

Movement Mechanism