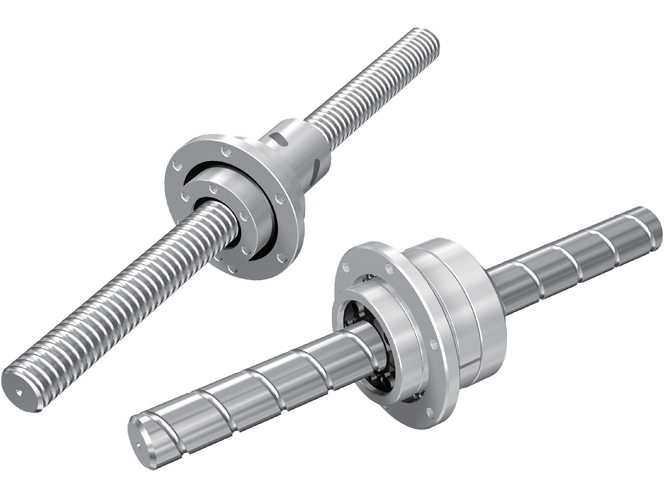

Precision Rotary Ball Screw

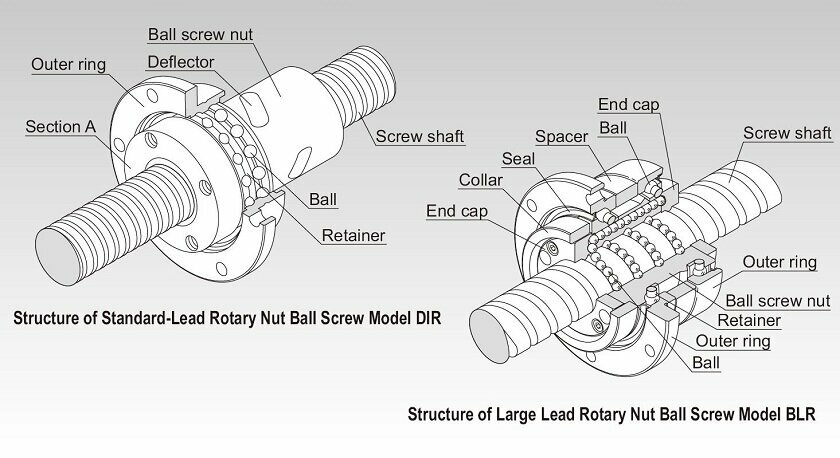

Model DIR Standard-Lead Rotary-Nut Ball Screw is a rotary-nut ball screw that has a structure where a simple-nut ball screw is integrated with a support bearing. Its ball screw nut serves as a ball recirculation structure using deflectors. Balls travel along the groove of the deflector mounted in the ball screw nut to the adjacent raceway, and then circulate back to the loaded area to complete an infinite rolling motion.

Model BLR is a rotary-nut ball screw unit that has an integrated structure

consisting of a ball screw nut and a support bearing.

Types

Highlight feature tags

- Large lead

- Preload

- No preload

- Offset preload

- End-cap type

- Deflector type

- Rotary nut

- Precision positioning (ball screw)

- Precision positioning (ball screw)

- Preload

- Offset preload

- Deflector type

- Rotary nut

Screw shaft diameter (mm) : 16,20,25,32,36,40

- Precision positioning (ball screw)

- Large lead

- No preload

- End-cap type

- Rotary nut

Screw shaft diameter (mm) : 16,20,25,32,36,40,50

Features

Structure and Features

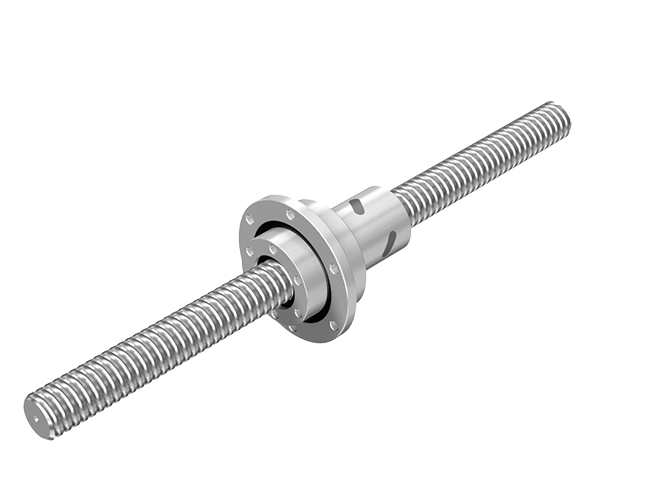

Model DIR

Model DIR Standard-Lead Rotary-Nut Ball Screw is a rotary-nut ball screw that has a structure where a simple-nut ball screw is integrated with a support bearing. Its ball screw nut serves as a ball recirculation structure using deflectors. Balls travel along the groove of the deflector mounted in the ball screw nut to the adjacent raceway, and then circulate back to the loaded area to complete an infinite rolling motion.

Being an offset preload nut, the single ball screw nut provides different phases to the right and left thread in the middle of the nut, setting the axial clearance below zero (providing a preload). This allows more compact, smoother motion to be achieved than the conventional double-nut type (a spacer is inserted between two nuts).

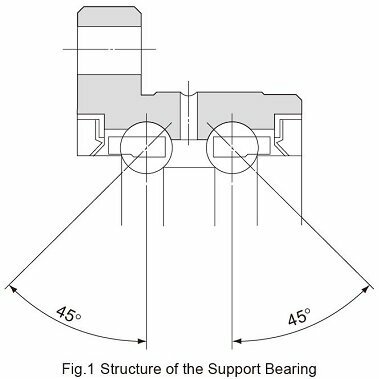

The support bearing comprised of two rows of Model DB angular bearings with a contact angle of 45°provides a preload. The collar, previously used to mount a pulley, is integrated with the ball screw nut. (See Section A)

● Compact

Because of the internal circulation mechanism using a deflector, the outer diameter is only 70% to 80% of that of the return-pipe nut, and the overall length is 60% to 80%, thus reducing the weight and decreasing the inertia during acceleration.

Since the nut and the support bearing are integrated, a highly accurate and compact design is achieved. In addition, small inertia due to the lightweight ball screw nut ensures high responsiveness.

● Capable of Fine Positioning

Being a standard-lead ball screw, it is capable of fine positioning despite the rotation of the ball screw nut.

● Accuracy Can Easily Be Achieved

As the outer ring of the support bearing is integrated, the bearing can be assembled with the nut housing on the end face of the outer ring flange. This makes it easy to center the ball screw nut and establish accuracy.

● Well-Balanced

Since the deflector is evenly positioned along the circumference, superb balance is ensured while the ball screw nut is rotating.

● Stability in the Low-Speed Range

Traditionally, motors tend to have an uneven torque and lower speeds due to the external factors. With this product, the motor can be connected independently with the screw shaft and the ball screw nut, thus allowing micro feeding within the motor’s stable rotation range.

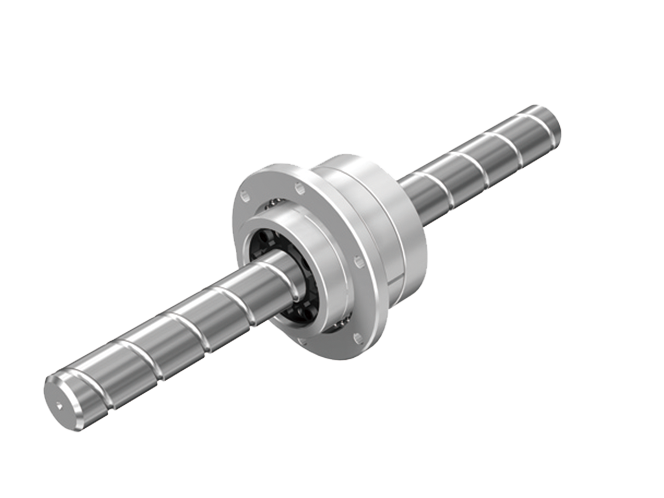

Model BLR

The rotary ball screw is a rotary-nut ball screw unit that has an integrated structure consisting of a ball screw nut and a support bearing. The support bearing is an angular bearing that has a contact angle of 60°, contains an increased number of balls and achieves a large axial rigidity.

Model BLR is divided into two types: the precision ball screw and the rolled ball screw.

● Smooth Motion

It achieves smoother motion than rack-and-pinion-based linear motion.

● Low Noise Even in High-Speed Rotation

Model BLR produces very low noise thanks to the balls being picked up along the end cap. In addition, the balls circulate by passing through the ball screw nut, allowing this model to be used quietly even at high speeds.

● High Rigidity

The support bearing of this model is larger than that of the screw shaft rotational type. Thus, its axial rigidity is significantly increased.

● Compact

Since the ball screw nut and the support bearing are integrated, a highly accurate and compact design is achieved.

● Easy Installation

By simply mounting this model to the housing with bolts, a ball screw nut rotating mechanism can be obtained. (For the housing’s inner-diameter tolerance, H7 is recommended.)