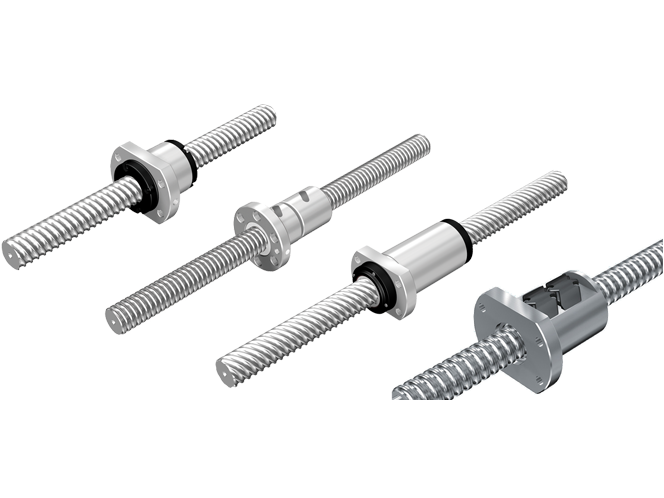

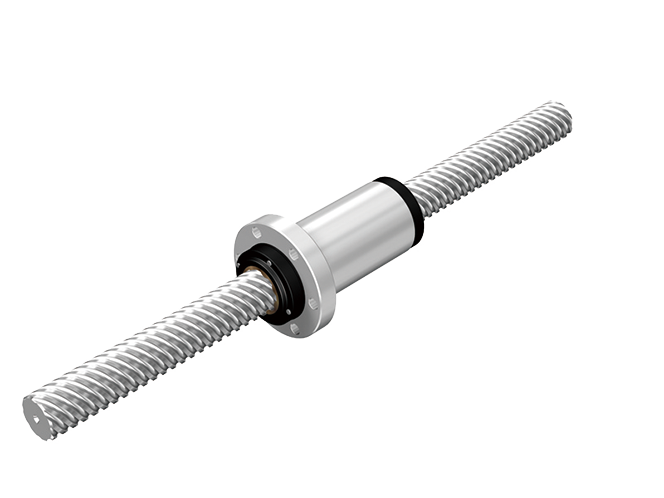

Full-Ball Type Rolled Ball Screw

THK rolled ball screws are low-priced feed screws that use a screw shaft both rolled with high accuracy and specially surface-ground, instead of a thread-ground shaft used in the precision ball screws.

The ball raceways of the ball screw nut are all thread-ground, thus achieving a smaller axial clearance and smoother motion than the conventional rolled ball screw.

In addition, a wide array of types are offered as standard in order to allow optimal products to be selected according to the application.

Types

Highlight feature tags

- Compact

- Miniature

- High speed

- Super lead

- Large lead

- Preload

- No preload

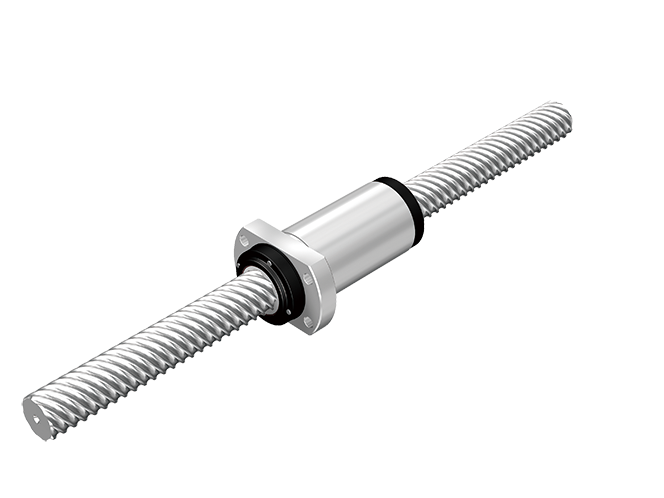

- Constant-pressure preload

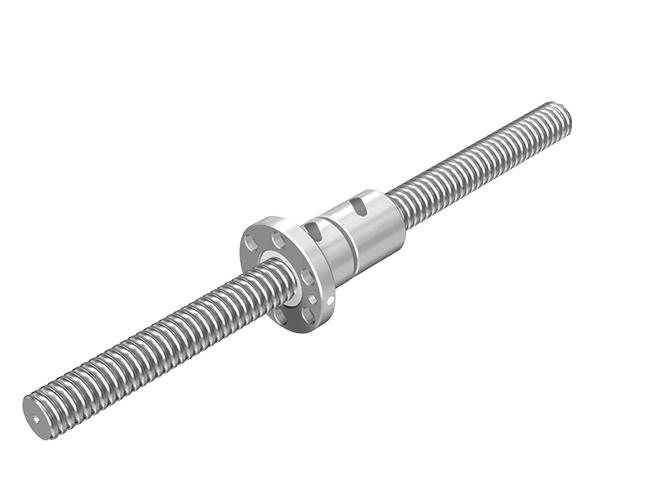

- Return-pipe type

- End-cap type

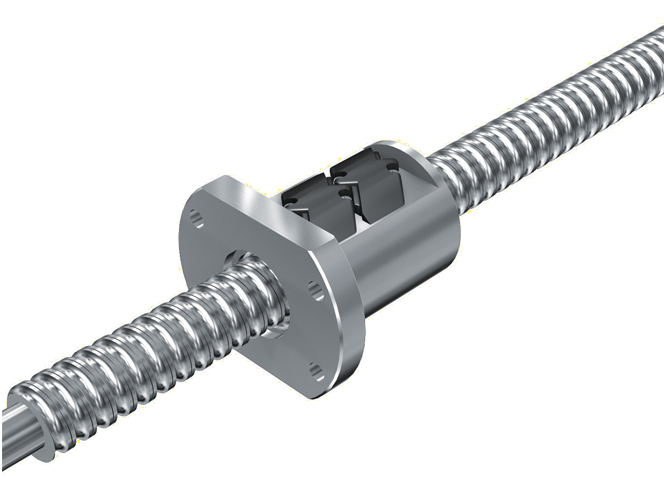

- Deflector type

- Slim nut

- Square nut

- Transport (ball screw)

- Transport (ball screw)

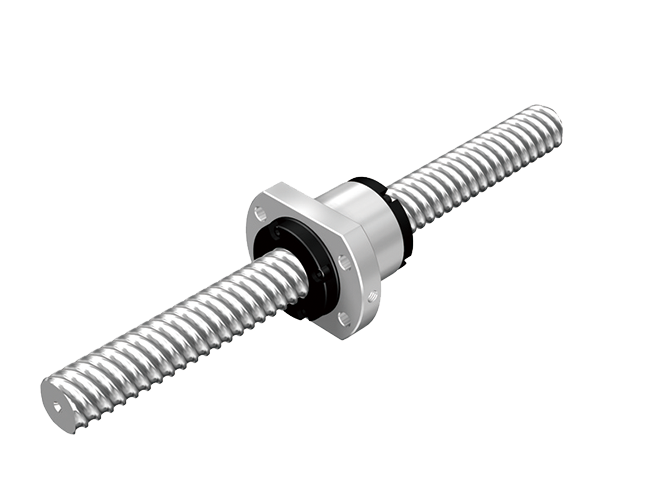

- Preload

- Constant-pressure preload

- Compact

- Deflector type

- Slim nut

Screw shaft diameter (mm) : 14,16,20,25,28,32,36,40

- Transport (ball screw)

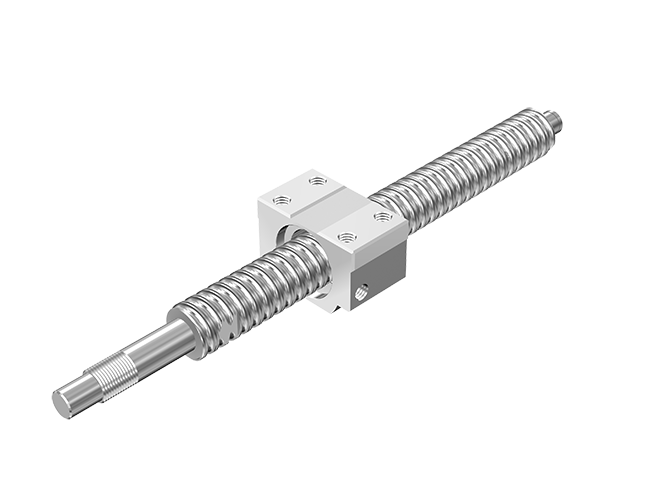

- No preload

- High speed

- Return-pipe type

Screw shaft diameter (mm) : 10,12,14,16,18,20,25,28,32,36,40,45,50

- Transport (ball screw)

- Super lead

- No preload

- End-cap type

Screw shaft diameter (mm) : 15,20,25,30,40,50

- Transport (ball screw)

- Super lead

- No preload

- End-cap type

Screw shaft diameter (mm) : 15,20,25,30

- Transport (ball screw)

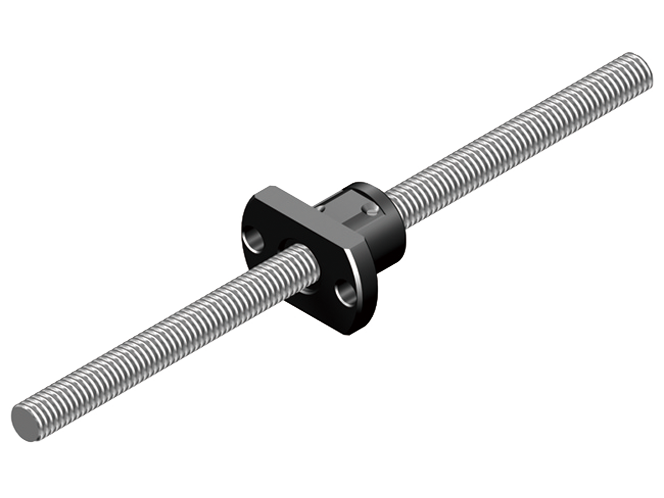

- No preload

- Return-pipe type

- Square nut

Screw shaft diameter (mm) : 14,16,18,20,25,28,32,36,45

- Transport (ball screw)

- No preload

- Compact

- Miniature

Screw shaft diameter (mm) : 06,08,10,12,14

- Transport (ball screw)

- Large lead

- No preload

- End-cap type

Screw shaft diameter (mm) : 08,10,15,16,20,25,32,36,40,50

Features

Structure and Features

THK Rolled Ball Screws are low priced feed screws that use a screw shaft rolled with high accuracy and specially surface-ground, instead of a thread-ground shaft used in the Precision Ball Screws.

The ball raceways of the ball screw nut are all thread-ground, thus achieving a smaller axial clearance and smoother motion than the conventional rolled ball screw.

In addition, a wide array of types are offered as standard in order to allow optimal products to be selected according to the application.

Achieves Lead Angle Accuracy of Class C7

Screw shafts with travel distance error of classes C7 and C8 are also manufactured as standard in addition to class C10 to meet a broad range of applications.

| Travel Distance Error | C7 | : ±0.05/300 (mm) |

| C8 | : ±0.10/300 (mm) | |

| C10 | : ±0.21/300 (mm) |

(For maximum manufacturing length of screw shaft by accuracy grade, seeAssuming the Shaft Lengthfor more information.)

Achieves Roughness of 0.20 a or Less for the Ball Raceways of the Screw Shaft

The surface of the screw shaft’s ball raceways is specially ground after the shaft is rolled to ensure surface roughness of 0.20 a or less, which is equal to that of the ground thread of the precision ball screw.

Ball Raceways of the Ball Screw Nut are Finished by Grinding

THK finishes the ball raceways of rolled ball screw nuts by grinding, just as the precision ball screws, to obtain durability and smooth motion.

Low Price

The screw shaft is induction-hardened or carburized after being rolled, and its surface is then specially ground. This allows the rolled ball screw to be priced lower than the precision ball screw with a ground thread.

High Contamination Protection

The ball screw nut is available with a compact labyrinth seal or a brush seal. This achieves low friction, high contamination protection, and a longer service life of the ball screw.