Precision Ball Screw with Unfinished Shaft Ends

This type of ball screw is mass-produced by cutting the standardized screw shafts of precision ball screws to fixed lengths. Additional machining of the shaft ends can easily be performed.

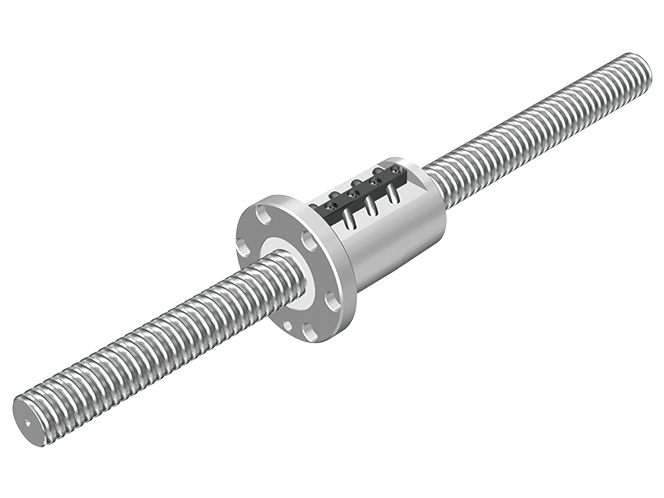

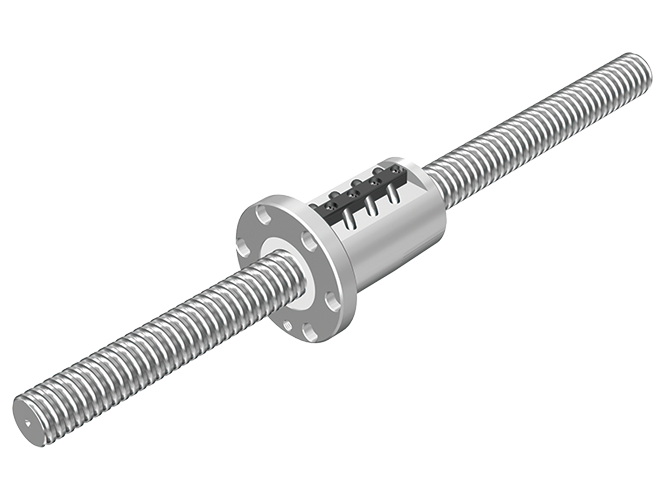

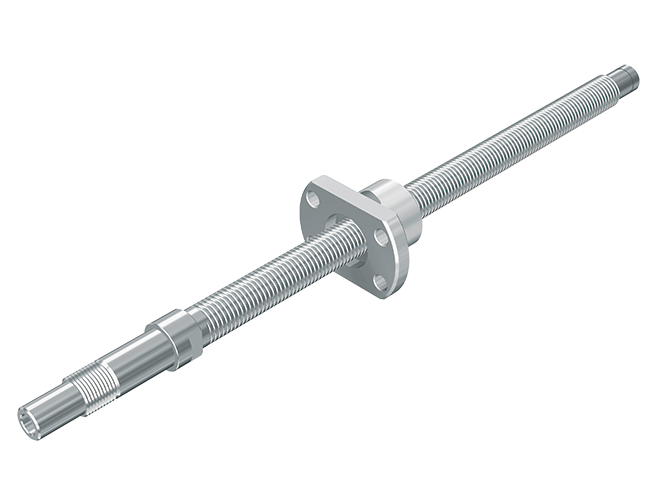

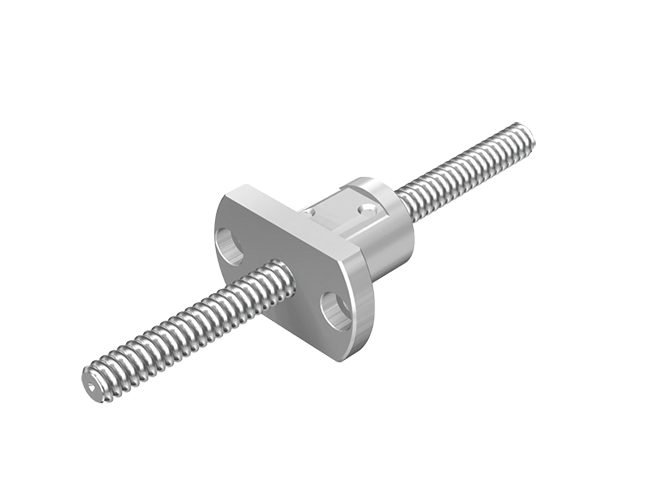

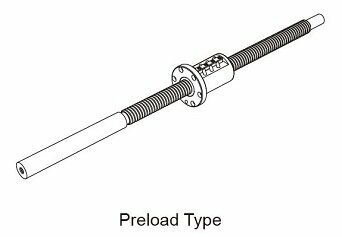

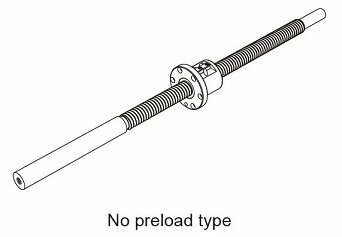

To meet various intended purposes, THK offers several ball screw models with different types of nuts: the single-nut type (Model BNF), the offset preload-nut type (Model BIF), and the miniature ball screw (Models MDK and MBF).

Types

Highlight feature tags

- Compact

- Miniature

- Screw shaft end additional machining

- Preload

- No preload

- Offset preload

- Return-pipe type

- Deflector type

- Precision positioning (ball screw)

- Precision positioning (ball screw)

- Screw shaft end additional machining

- Preload

- Offset preload

- Return-pipe type

Screw shaft diameter (mm) : 16,18,20,25,28,32,36,40,50

- Precision positioning (ball screw)

- Screw shaft end additional machining

- No preload

- Return-pipe type

Screw shaft diameter (mm) : 16,18,20,25,28,32,36,40,50

- Precision positioning (ball screw)

- Screw shaft end additional machining

- No preload

- Compact

- Miniature

- Deflector type

Screw shaft diameter (mm) : 04,06,08,10,12,14

- Precision positioning (ball screw)

- Screw shaft end additional machining

- No preload

- Compact

- Miniature

Screw shaft diameter (mm) : 04,06,08,10,12,14

Features

Structure and Features

This type of ball screw is mass-produced by cutting the standardized screw shafts of precision ball screws to fixed lengths. Additional machining of the shaft ends can easily be performed.

To meet various intended purposes, THK offers several ball wcrew models with different types of nuts: the single-nut type (Model BNF), the offset preload-nut type (Model BIF), and the miniature ball screw (Models MDK and MBF).

Contamination Protection

Nuts of the following model numbers have a labyrinth seal attached.

- All variations of Models BNF and BIF

- Model MDK0802/1002/1202/1402/1404/1405

When the inflow of dust or foreign material is possible, it is necessary to use a dust-prevention device (e.g. bellows) to completely cover the ball screw.

Lubrication

The ball screw nuts are sealed with lithium soap-based grease at shipment.

(Models MDK and MBF only have an anti-rust oil applied.)

Additional Machining of the Shaft End

Since only the effective thread of the screw shaft is treated with induction hardening (all variations of Models BNF and BIF and Model MDK 1405) or carburizing (all variations of Model MBF and Model MDK0401 to 1404), the shaft ends can additionally be machined easily either by grinding or milling.

In addition, since both ends of the screw shaft have a center hole, they can be cylindrically ground.

| Surface hardness of the effective thread | : 58 to 64 HRC |

| Hardness of the screw shaft ends | |

| All variations of Models BNF and BIF, Model MDK 1405 | : 22 to 27 HRC |

| All variations of Model MBF, Model MDK0401 to 1404 | : 35 HRC or less |

THK has standardized the shaft end shapes of the screw shafts in order to allow speedy quotation and manufacturing of ball screws.

The shapes for shaft ends include Models H, K, and J, which allow standard Support Units to be used. SeeBall Screw Peripherals Support Unitfor more information.

Nut Types and Axial Clearance

|

Screw shaft outer diameter (mm) |

ø 4 to ø 14 |

|||

|---|---|---|---|---|

|

Nut type |

Model MDK |

Model MBF |

||

|

|

|||

|

Accuracy grades |

C3, C5 |

C7 |

C3, C5 |

C7 |

|

Axial clearance (mm) |

0.005 or less (GT) |

0.02 or less (G2) |

0.005 or less (GT) |

0.02 or less (G2) |

Note: The notation in the parentheses indicate the axial clearance symbol.

|

Screw shaft outer diameter (mm) |

ø 16 to ø 50 |

|||

|---|---|---|---|---|

|

Nut type |

Model BIF |

Model BNF |

||

|

|

|||

|

Accuracy grades |

C5 |

C7 |

C5 |

C7 |

|

Axial clearance (mm) |

0 or less (G0) |

0 or less (G0) |

0.01 or less (G1) |

0.02 or less (G2) |

Note) The notation in the parentheses indicate axial clearance code.