Checking List for Spline Shaft End Shape

If desiring a ball spline type with its end specially machined, check the following items when placing an order.

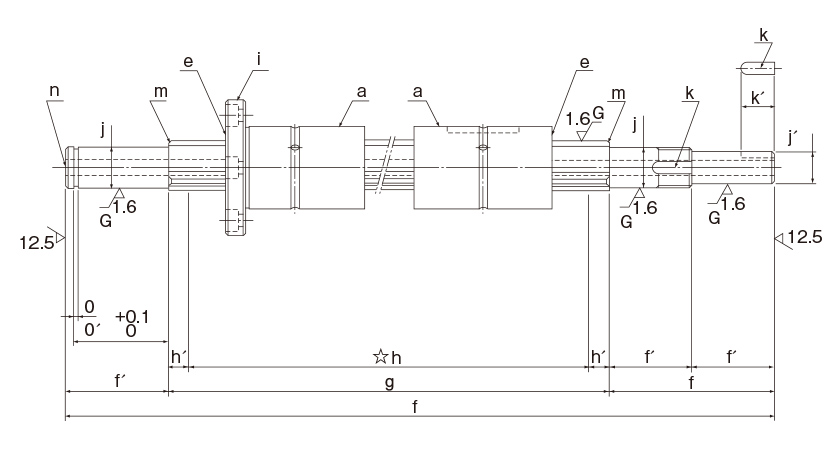

The diagram below shows a basic configuration of the Ball Spline.

Check Items

- Type of the spline nut to be fit

- Number of spline nuts

- Clearance in the rotation direction

- Accuracy

- With/without a seal (for a single seal, check its orientation)

- Overall length (including all dimensions? Total value correct?)

- Effective spline length

- Hardened area (mark the location with symbol ☆ and indicate the purpose of hardening)

- Orientation of the flange (for flanged type)

- Spline shaft end shape (thicker than the minimum spline diameter?) (black, mill scale)

- Positional relationship between the spline nut and the spline shaft end shape (keyway of the spline nut, flange mounting hole)

- Indication of chamfering for each part

- Shape of chamfer on the spline shaft end (see Chamfering of the Spline Shaft Ends )

- Intended purpose of the though hole in the spline shaft if any

- o’. Snap ring groove

- Maximum length

- Precedented or not