High Torque Type Ball Spline

With the high-torque ball spline, the spline shaft has three crests positioned equidistantly at 120°, and along both sides of each crest, two rows of balls (six rows in total) are arranged so as to hold the crest.

The raceways are precision ground into curved grooves whose diameters are approximate to the ball diameter. When a torque is generated from the spline shaft or the spline nut, the three rows of balls on the load-bearing side evenly receive the torque, and the center of rotation is automatically determined. When the rotation reverses, the remaining three rows of balls on the opposite side receive the torque.

The rows of balls are held in a cage incorporated in the spline nut so that they stay aligned and recirculate. With this design, balls will not fall even if the spline shaft is removed from the nut.

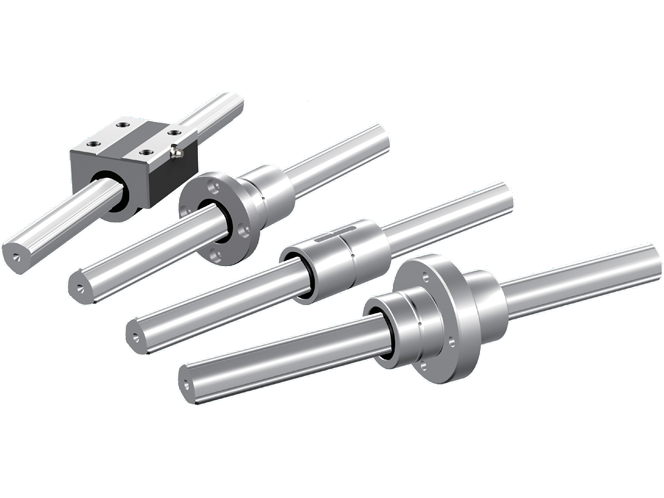

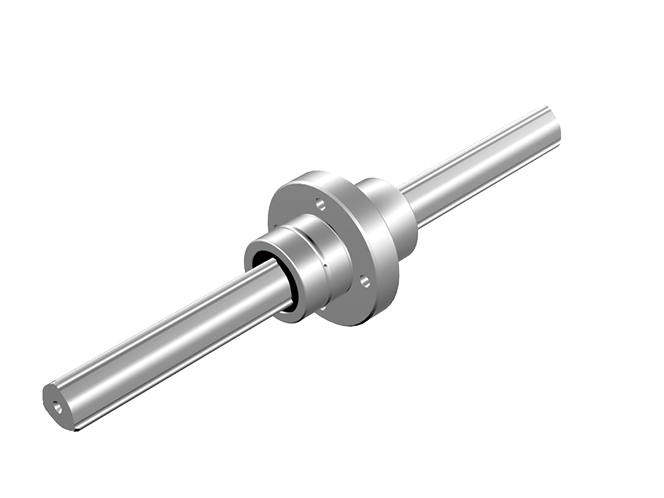

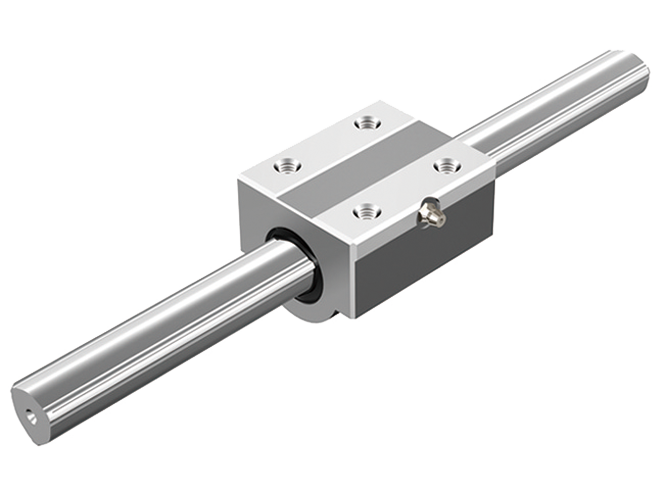

Types

Highlight feature tags

- Long type

- High torque

- Square nut

- Flanged type

- Cylindrical type

- Solid spline shaft

- Hollow spline shaft

- High torque

- Cylindrical type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 15,20,25,30,40,50,70,85,100

- High torque

- Long type

- Cylindrical type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 20,25,30,40,50,60,70,85,100,120,150

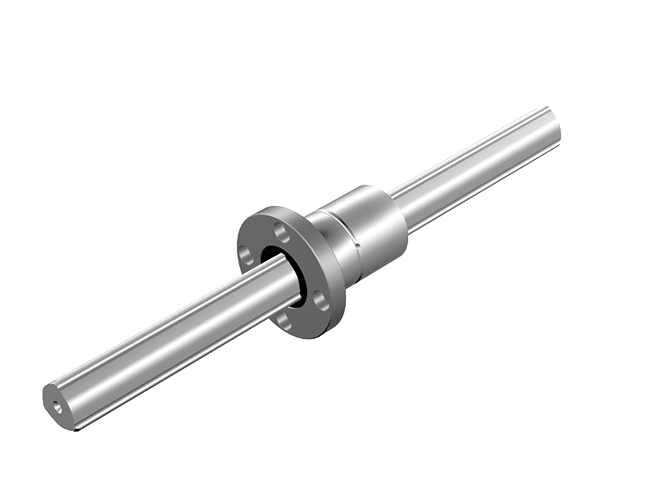

- High torque

- Flanged type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 15,20,25,30,40,50,60,70,85,100

- High torque

- Flanged type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 15,20,25,30,40,50,60,70,85,100

- High torque

- Square nut

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 15,20,25,30,40,50

Features

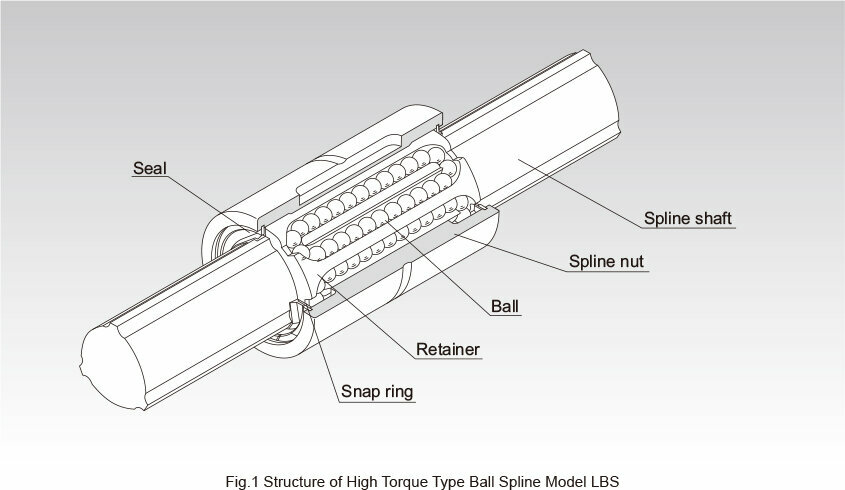

Structure and Features

With the high torque type Ball Spline, the spline shaft has three crests positioned equidistantly at 120°, and along both sides of each crest, two rows of balls (six rows in total) are arranged so as to hold the crest, as shown in Fig.1 . The raceways are precision ground into R-shaped grooves whose diameters are approximate to the ball diameter. When a torque is generated from the spline shaft or the spline nut, the three rows of balls on the load-bearing side evenly receive the torque, and the center of rotation is automatically determined. When the rotation reverses, the remaining three rows of balls on the unloaded side receive the torque. The rows of balls are held in a retainer incorporated in the spline nut so that they smoothly roll and circulate. With this design, balls will not fall even if the spline shaft is removed from the nut.

No Angular Backlash

With the high torque type Ball Spline, a single spline nut provides a preload to eliminate angular backlash and increase the rigidity. Unlike conventional ball splines with circular-arc groove or Gothic-arch groove, the high torque type Ball Spline eliminates the need for twisting two spline nuts to provide a preload, thus allowing compact design to be achieved easily.

High Rigidity and Accurate Positioning

Since this model has a large contact angle and provides a preload from a single spline nut, the initial displacement is minimal and high rigidity and high positioning accuracy are achieved.

High-speed Motion, High-speed Rotation

Adoption of a structure with high grease retention and a rigid retainer enables the ball spline to operate over a long period with grease lubrication even in high-speed straight motion. Since the distance in the radius direction is almost uniform between the loaded balls and the unloaded balls, the balls are little affected by the centrifugal force and smooth straight motion is achieved even during high-speed rotation.

Compact Design

Unlike conventional ball splines, unloaded balls do not circulate on the outer surface of the spline nut with this model. As a result, the outer diameter of the spline nut is reduced and a space-saving and compact design is achieved.

Ball Retaining Type

Use of a retainer prevents the balls from falling even if the spline shaft is pulled out of the spline nut.

Can be Used as a Linear Bushing for Heavy Loads

Since the raceways are machined into R grooves whose diameter is almost equal to the ball diameter, the contact area of the ball is large and the load capacity is large also in the radial direction.

Double, Parallel Shafts can be Replaced with a Single Shaft

Since a single shaft is capable of receiving a load in the torque direction and the radial direction, double shafts in parallel configuration can be replaced with a single-shaft configuration. This allows easy installation and achieves space-saving design.

Applications

The high torque type Ball Spline is a reliable straight motion system used in a wide array of applications such as the columns and arms of industrial robot, automatic loader, transfer machine, automatic conveyance system, tire forming machine, spindle of spot welding machine, guide shaft of high-speed automatic coating machine, riveting machine, wire winder, work head of electric discharge machine, spindle drive shaft of grinding machine, speed gears and precision indexing shaft.

Types of Spline Shafts

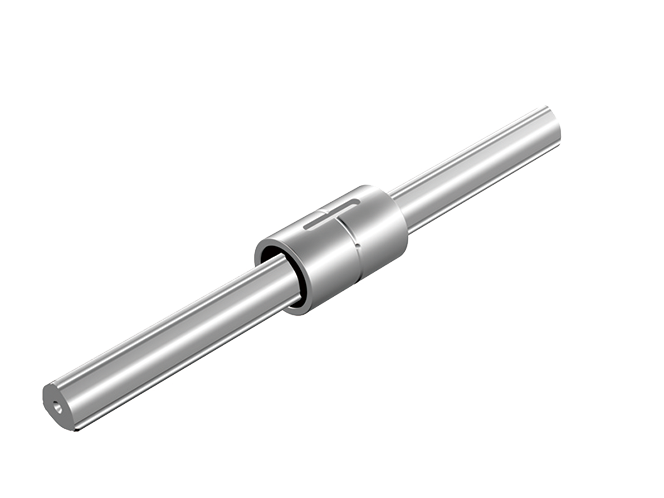

Precision Solid Spline Shaft (Standard Type)

Special Spline Shaft

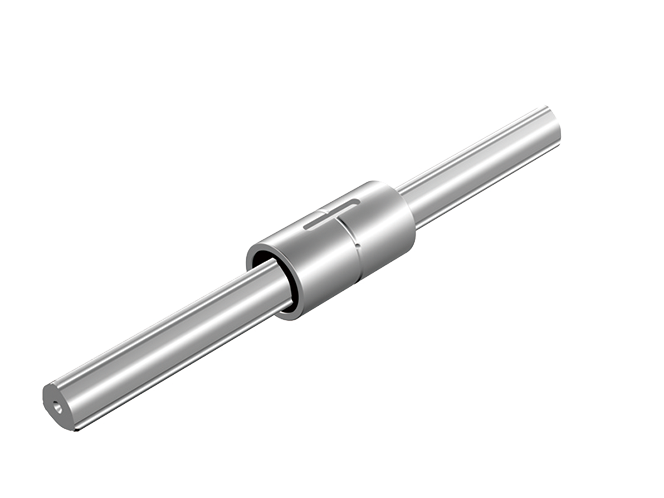

Hollow Spline Shaft (Type K)

Housing Inner-diameter Tolerance

When fitting the spline nut to the housing, transition fit is normally recommended. If the accuracy of the Ball Spline does not need to be very high, clearance fitting is also acceptable.

|

Housing Inner-diameter Tolerance |

General conditions |

H7 |

|---|---|---|

|

When clearance needs to be small |

J6 |