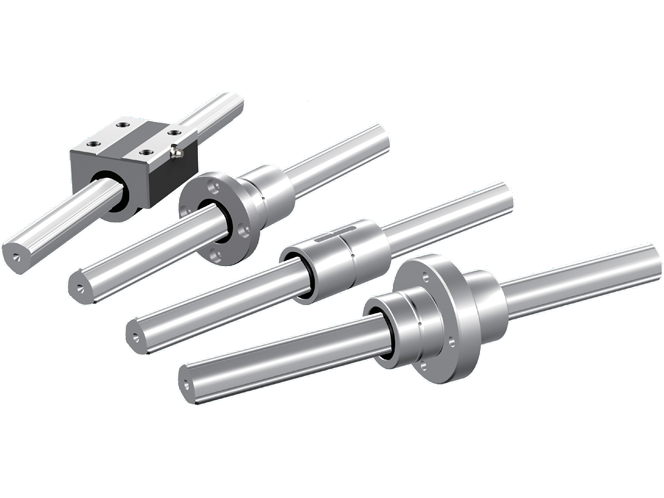

With the high-torque ball spline, the spline shaft has three crests positioned equidistantly at 120°, and along both sides of each crest, two rows of balls (six rows in total) are arranged so as to hold the crest.

The raceways are precision ground into curved grooves whose diameters are approximate to the ball diameter. When a torque is generated from the spline shaft or the spline nut, the three rows of balls on the load-bearing side evenly receive the torque, and the center of rotation is automatically determined. When the rotation reverses, the remaining three rows of balls on the opposite side receive the torque.

The rows of balls are held in a cage incorporated in the spline nut so that they stay aligned and recirculate. With this design, balls will not fall even if the spline shaft is removed from the nut.