Rotary Ball Spline with Gear

With the rotary ball spline, the spline shaft has three crests, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

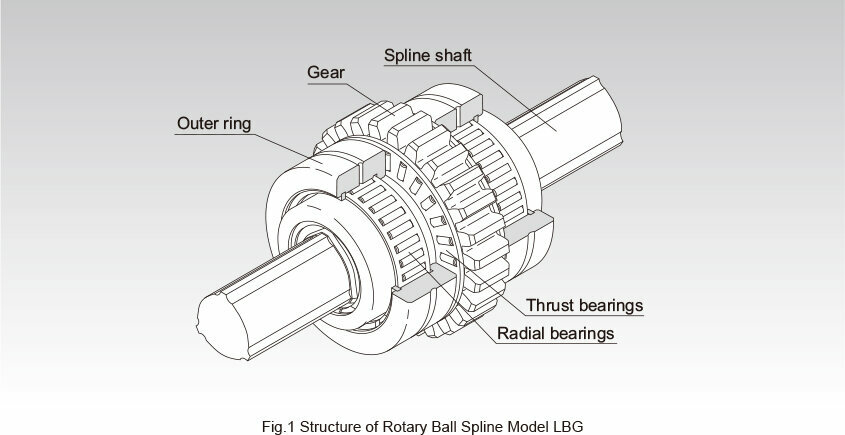

These models are unit types based on the Model LBR, but have gear teeth on the flange circumference and radial and thrust bearings on the spline nut, all compactly integrated.

The rows of balls are held in a special resin cage so that they stay aligned and recirculate. With this design, balls will not fall even if the spline shaft is removed.

Types

Highlight feature tags

- Rotary and linear motions

- Rotary

- With a thrust raceway

- With gear

- Solid spline shaft

- Hollow spline shaft

- Rotary and linear motions

- Rotary

- With gear

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 20,25,30,40,50,60,85

- Rotary and linear motions

- Rotary

- With a thrust raceway

- With gear

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 20,25,30,40,50,60,85

Features

Structure and Features

With the Rotary Ball Spline, the spline shaft has three crests, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied. These models are unit types based on model LBR, but have gear teeth on the flange circumference and radial and thrust bearings on the spline nut, all compactly integrated. The rows of balls are held in a special resin retainer so that they smoothly roll and circulate. With this design, balls will not fall even if the spline shaft is removed.

No Angular Backlash

The spline shaft has three crests positioned equidistantly at 120° and along both sides of each crest, two rows of balls (six rows in total) are arranged so as to hold the crest at a contact angle of 45° and provide a preload. As a result, backlash in the rotational direction is eliminated and the rigidity is increased.

Compact Design

The spline nut is compactly integrated with radial and thrust bearings, allowing compact design to be achieved.

High Rigidity

Since the contact angle is large and an appropriate preload is given, high rigidity against torque and moment is achieved.Use of needle bearings in the support unit achieves a rigid nut support strong against a radial load.

Optimal for Torque Transmission with Spline Nut Drive

Since the support bearings allow a rigid nut support, these models are optimal for torque transmission with spline nut drive.

Types and Features

Types of Spline Shafts

Precision Solid Spline Shaft (Standard Type)

The spline shaft is cold-drawn and its raceway is precision ground. It is used in combination with a spline nut.

Special Spline Shaft

THK manufactures a spline shaft with thicker ends or thicker middle area through special processing at your request.

Hollow Spline Shaft (Type K)

A drawn, hollow spline shaft is available for requirements such as piping, wiring, air-vent and weight reduction.

Housing Inner-diameter Tolerance

Table1 shows housing inner-diameter tolerance for models LBG and LBGT.

| Housing Inner-diameter Tolerance | General conditions | H7 |

|---|---|---|

| When clearance needs to be small | J6 |