Cross-Roller Guide/Ball Guide Cross-Roller Guide with Cage Alignment System VRG

Adopts a proprietary rack and pinion system to prevent ball cage misalignment and achieve stable motion.Features more rollers than its predecessor, the Model VR, and achieves a high basic load rating.Possesses the same mounting dimensions as the Model VR

Types

Highlight feature tags

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 0.83 to 4.06 / Basic static load rating 1.09 to 8.15

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 2.47 to 11.4 / Basic static load rating 3.31 to 23.1

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 7.07 to 23.6 / Basic static load rating 10.4 to 48.4

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 16.4 to 54.7 / Basic static load rating 23.0 to 107

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 16.4 to 54.7 / Basic static load rating 23.0 to 107

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 0.83 to 4.06 / Basic static load rating 1.09 to 8.15

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 2.47 to 11.4 / Basic static load rating 3.31 to 23.1

- High rigidity

- High corrosion resistance

- Long service life

- Cage alignment system

Basic load rating (kN) : Basic dynamic load rating 7.07 to 23.6 / Basic static load rating 10.4 to 48.4

Features

Prevents cage misalignment

THK’s proprietary rack and pinion mechanism prevents cage misalignment caused by impacts and the vibrations and inertia of running equipment.

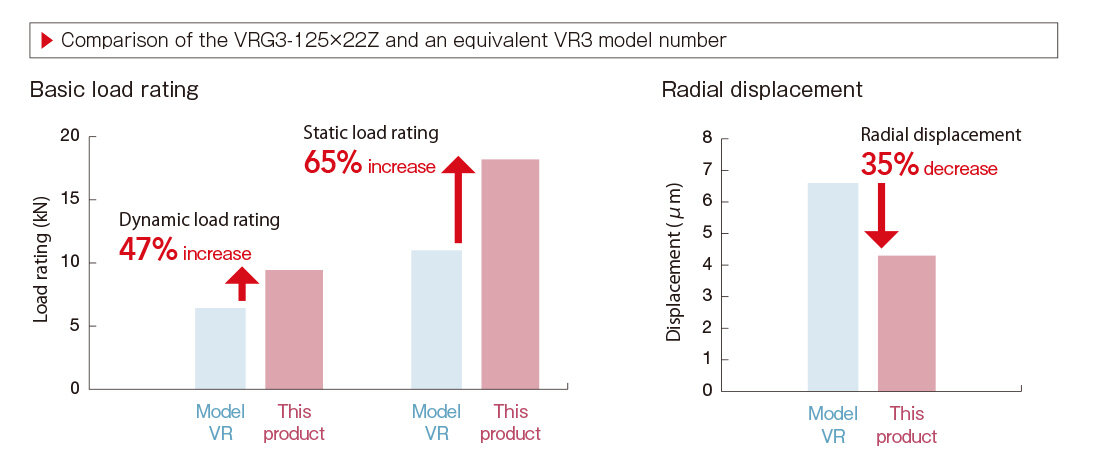

Long service life and high rigidity

Compared to the current Model VR, the Cross-Roller Guide with Cage Alignment System has more rollers and drastically improved basic load rating and rigidity.

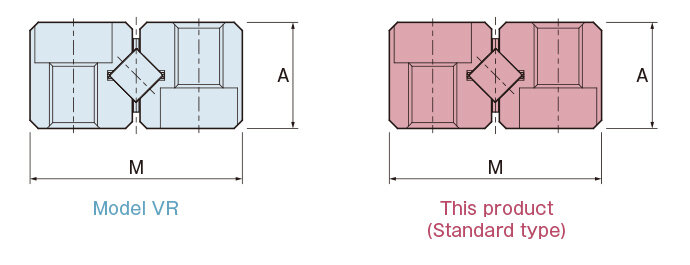

Interchangeable mounting dimensions

The standard Cross-Roller Guide with Cage Alignment System can easily replace the current Model VR, as it has the same mounting dimensions.

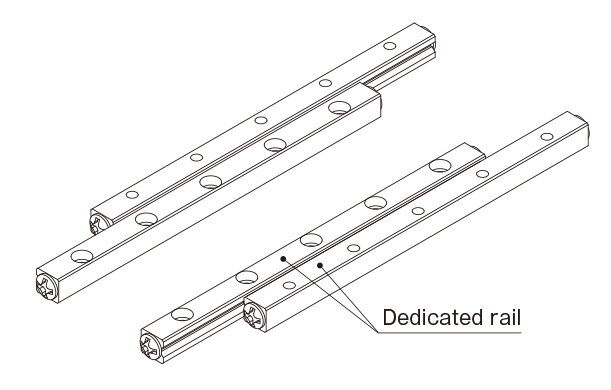

Structure of the Cross-Roller Guide with Cage Alignment System

This lightweight, finite stroke linear guide product is composed of precision rollers held in an orthogonal orientation by a cage that is assembled onto a dedicated rail. As a result, it can bear loads in every direction. It also has a high degree of rigidity and, being made of stainless steel, is extremely corrosion- resistant. Additionally, this product achieves accurate motion and maintains cage alignment through the use of a rack and pinion system.

Lineup

Standard type

The standard type can replace the Model VR because their mounting dimensions are interchangeable. It can also be installed with the desired spacing, making it a product that offers a high degree of design flexibility.

Center rail type

The center rail type combines the two inner rails of the standard type into a single rail. This makes installation easier and allows for the construction of a table unit with a more compact width.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |