Flat Roller Precautions on Use

Handling

- Do not disassemble the parts. This will result in loss of functionality.

- Take care not to drop or strike the Flat Roller. Doing so may cause injury or damage. Giving an impact to it could also cause damage to its function even if the product looks intact.

- When handling the product, wear protective gloves, safety shoes, etc., as necessary to ensure safety.

Precautions on Use

- Prevent foreign material, such as cutting chips or coolant, from entering the product. Failure to do so may cause damage.

- If the product is used in an environment where cutting chips, coolant, corrosive solvents, water, etc., may enter the product, use bellows, covers, etc., to prevent them from entering the product.

- If foreign material such as cutting chips adheres to the product, replenish the lubricant after cleaning the product.

- Do not use the product at temperature of 100℃ or higher.

- The Flat Roller cannot be used as a roller conveyor.

- The roller cage may driftas affected by a moment load, vertical mounting, uneven contact and machine vibrations. If the cage drift is not absolutely allowed, using an infinite type LM Guide system is considered.

- Insufficient rigidity or accuracy of mounting members causes the bearing load to concentrate on one point and the bearing performance will drop significantly. Accordingly, give sufficient consideration to the rigidity/accuracy of the housing and base and strength of the fixing bolts.

Contamination Protection and Lubrication

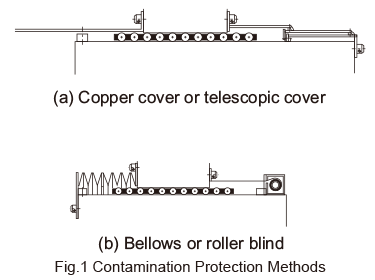

- With the Flat Roller, once foreign material enters the raceway due to poor contamination protection, it cannot be removed easily and tends to severely damage the raceway or the Flat Rollers.Therefore, use much care in contamination protection. Normally, for contamination protection of the Flat Roller, a bellows or a telescopic cover that covers the whole sliding surface, as shown in Fig.1 , is effective.

-

The required quantity of lubricant is much smaller than sliding metals, making the lubrication control easy.

Since the Flat Roller has high lubricant retention, it is suitable for grease lubrication.It is preferable to use lithium-soap group grease No. 2, or slightly viscous sliding surface oil or turbine oil.

- When lubricating the product, apply grease directly on the raceway and give several break-in strokes.

- Do not mix different lubricants. Mixing greases using the same type of thickening agent may still cause adverse interaction between the two greases if they use different additives, etc.

- Micro-strokes tend to obstruct oil film to form on the raceway in contact with the rolling element, and may lead to fretting corrosion. Take consideration using grease offering excellent fretting prevention. Accordingly, use grease offering excellent fretting toughness. It is also recommended that a long-stroke movement be made on a regular basis to make sure oil film is formed between the raceway and rolling element.

- When using the product in locations exposed to constant vibrations or in special environments such as clean rooms, vacuum and low/high temperature, use the grease appropriate for the specification/environment.

- The consistency of grease changes according to the temperature. Take note that the slide resistance of the Flat Roller also changes as the consistency of grease changes.

- After lubrication, the slide resistance of the Flat Roller may increase due to the agitation resistance of grease. Be sure to perform a break-in to let the grease spread fully, before operating the machine.

- Excess grease may scatter immediately after lubrication, so wipe off scattered grease as necessary.

- The properties of grease deteriorate and its lubrication performance drops over time, so grease must be checked and added properly according to the use frequency of the machine.

- The greasing interval varies depending on the use condition and service environment. Set the final lubrication interval/amount based on the actual machine.

Attaching the Stopper

Although the Flat Roller performs extremely accurate motion, it may cause a traveling error due to uneven load distribution or non-uniform stop. Therefore, we recommend attaching a stopper on the end of the base or the table.

Chamfering the End Face of the Table

If the Flat Roller is longer than the overall table length, finely chamfer the end face of the table so that the rollers are easily fed to the table.

Mounting Precision

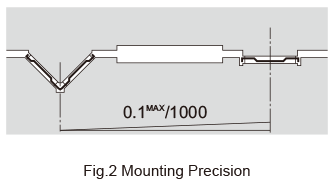

To maximize the performance of the Flat Roller, it is necessary to distribute the load as evenly as possible when mounting the product. Fig.2 For the allowable tilt as shown in , we recommend 0.1 mm or less against 1,000 mm.

Storage

When storing the Flat Roller, enclose it in a package designated by THK and store it in a room in a horizontal orientation while avoiding high temperature, low temperature and high humidity.

Disposal

Dispose of the product properly as industrial waste.