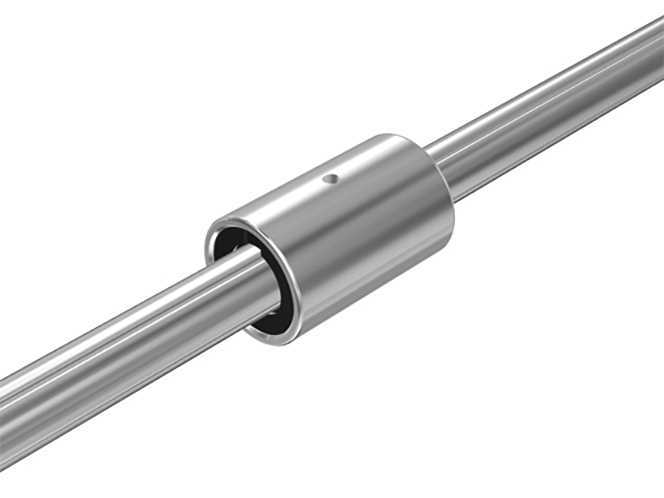

Guide Ball Bushing

Since the Model LG has four rows of circular arc grooves (raceways), it does not need a mechanism to prevent the outer nut from rotating. In addition, its load rating is much larger than a Model LM linear bushing with the same dimensions. Therefore, replacing the linear bushing with the guide ball bushing will reduce the size and cost of the guide unit and extend the service life.

Types

Highlight feature tags

- Compact

- Long service life

- Circular-arc groove

- Long service life

- Compact

- Circular-arc groove

Shaft Diameter (mm) : 4,6,8

Features

Structure and Features

Since model LG has 4 rows of circular arc grooves (raceways), it does not need a mechanism to prevent the outer tube from rotating. In addition, its load rating is much larger than Linear Bushing model LM with the same dimensions. Therefore, replacing the Linear Bushing with the Guide Ball Bushing will reduce the size and cost of the guide unit and extend the service life.

Higher Load Rating than the Linear Bushing

Since model LG ensures an R contact through the use of circular arc grooves for ball contact, it achieves a load rating more than twice that of point-contact Linear Bushing model LM with the same size.

A Rotation Stopper is Unnecessary Because of Raceways

Since model LG has circular arc grooves, it does not need a rotation stopper required for Linear Bushing model LM, and allows the machine design to be compact.

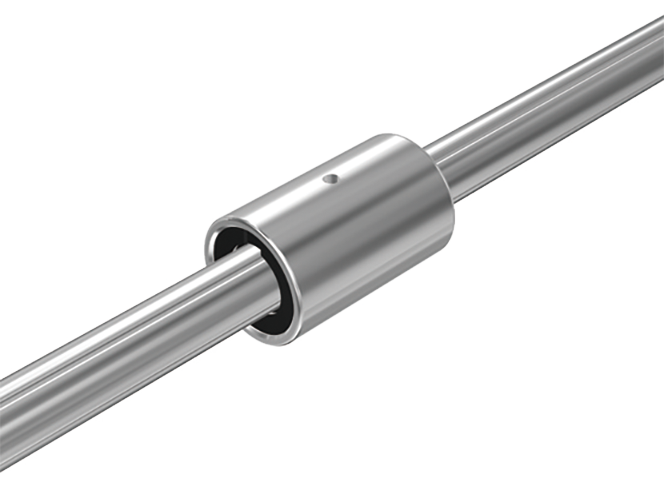

Interchangeable in Dimensions with Linear Bushing Model LM

Since the outer tube of model LG has the same outer diameter and length as that of Linear Bushing model, LM, it is possible to replace Linear Bushing model LM with Guide Ball Bushing model LG as assemblies.

Various Combinations of Nut and Shaft are Available (Any Combination is Allowed)

As with the Linear Bushing, any combination of the LG nut and the LG shaft of model LG is allowed.

Examples of Changing the Linear Bushing to the Guide Ball Bushing

Advantage of using the Guide Ball Bushing 1: Longer service life

Since model LG has a rated load more than 2.4 times the Linear Bushing with the same dimensions, replacing the Linear Bushing with model LG will increase the service life by more than 13.8 times.

|

Model No. |

Basic dynamic load rating: |

Load rating ratio |

Service life ratio |

|---|---|---|---|

|

LG4S |

335 |

3.8 times |

54.8 times |

|

LM4 |

88.2 |

||

|

LG6S |

494 |

2.4 times |

13.8 times |

|

LM6 |

206 |

||

|

LG8S |

796 |

3.0 times |

27.0 times |

|

LM8 |

265 |

Advantage of using the Guide Ball Bushing 2: Smaller machine size

Since the Linear Bushing is not suitable for applications where a load in the rotational direction is applied, it is necessary to use two or more Linear Bushing units in parallel or have a rotation stopper mechanism even under conditions where a torque is not applied. In contrast, the Guide Ball Bushing, which has a structure containing four rows of circular arc grooves, is operable with a single shaft and therefore contributes to downsizing the machine, unless an excessive load is applied.

Achieves a load carrying capacity approximately three times the Linear Bushing in a half space

|

Model No. |

Permissible moment: M A[N・m] |

|---|---|

|

One unit of LG8S is used |

1.46 |

|

Two units of LM8 are used |

0.45 |