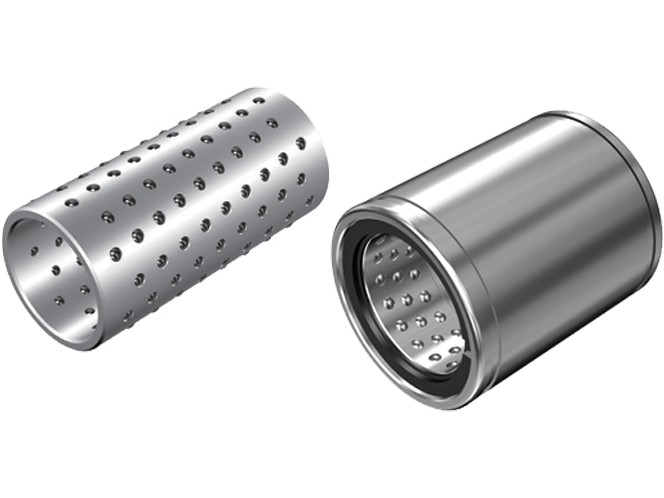

The Model ST has a ball cage and balls both incorporated into a precision-ground cylindrical nut. The balls are in a staggered array so as to evenly receive loads. The ball cage is a drilled cage made of a light alloy with high rigidity, and it is capable of high-speed motion. A thrust ring and a snap ring are installed on both sides of the inner surface of the nut to prevent the ball cage from overshooting.

This structure allows rotational motion, reciprocal motion, and combined motion with a small friction coefficient. It has a stroke length up to twice the range within which the ball cage can travel inside the nut.

Since high accuracy can be obtained at a low price, this model is used in a wide array of applications such as press die sets, printing machine ink roll units, punching press workpiece chuck units, press feeders, electric discharge machine work heads, wound roll correctors, spinning and weaving machines, distortion measuring equipment, optical measuring instrument spindles ,and photocopiers.

The Model MST consists of an ST shaft, ball cage, and nut. These components can freely be combined depending on the specifications. The cross-sectional shape is small, the clearance is minimal, and the motion is extremely light and smooth. As a result, the Model MST can be used in a variety of small, precision measuring equipment such as spindles in optic measuring instruments, pen plotters, office automation equipment, computer terminals, automatic scales, digital length measuring machines, and solenoid valves.

With Models KS and BS, a large number of precision steel balls (difference in sphericity: 0.0005 mm) compliant with JIS B 1501 are incorporated in a lightweight, highly rigid ball cage. The balls are arranged along the circumference of the ball cage in spirals so that the ball raceways do not overlap with each other. It enables these models to be used over a long period without wear and to demonstrate high durability. In addition, the ball pockets, which hold the balls, are finished with precision and continuously caulked with a unique process, enabling them to prevent the balls from falling. It allows the system to travel smoothly even if the ball cage is longer than the housing. These ball cages are used in precision press die sets, spinning and weaving machines, precision measuring instruments, automatic recorders, medical equipment, and various machine tools.