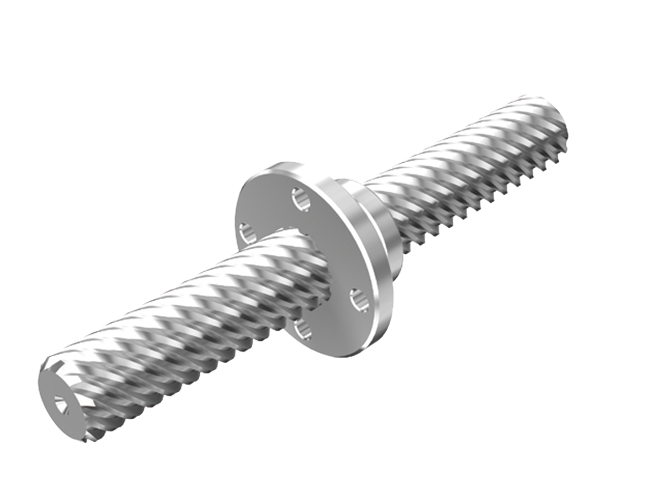

The Change Nut Models DCMA and DCMB have a lead angle of 45°, which is difficult to achieve through machining. Each model is capable of converting linear motion into rotary motion, or vice-versa, at high efficiency. Because of the large leads, they are optimal for providing a fast-feed mechanism at low-speed rotation. The multi-thread screw shafts to be combined with these change nuts are formed through cold gear rolling. The surface of the teeth is hardened to over 250 HV and mirror-finished. As a result, the shafts are highly wear-resistant and achieve significantly smooth motion when used in combination with these change nuts. Models DCMA40, DCMB40, or higher are designed for use in combination with cut screw shafts.

Miniature change nuts are made of an oil-impregnated plastic,

enabling them to have wear resistance and excel in lubrication especially in an oil-less operation. In addition, since the high level of their performance can be maintained for a long period, they enable long-term maintenance-free operation.