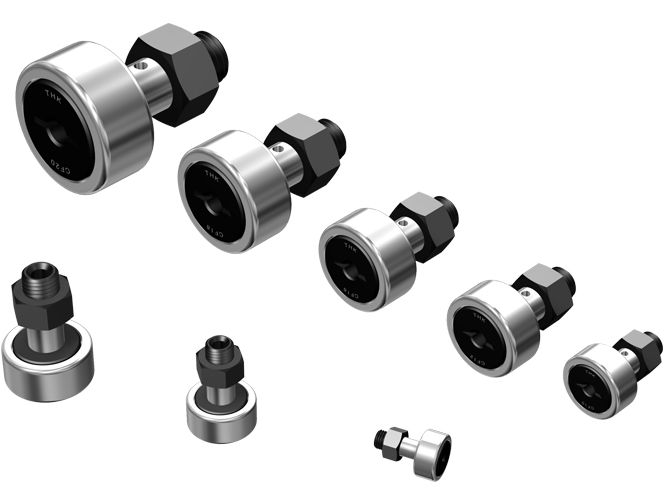

Cam Follower

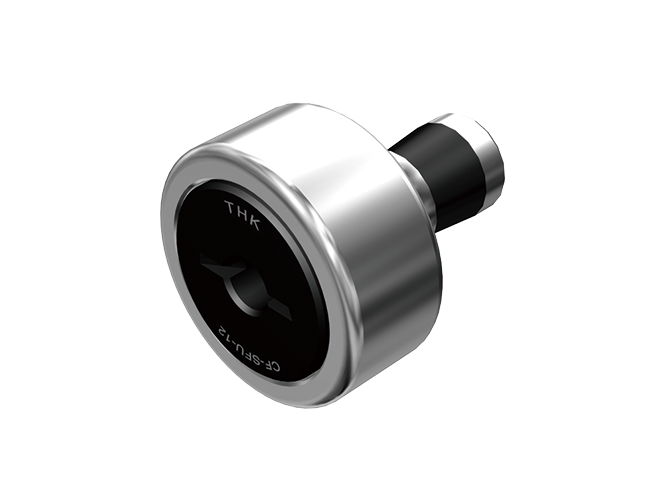

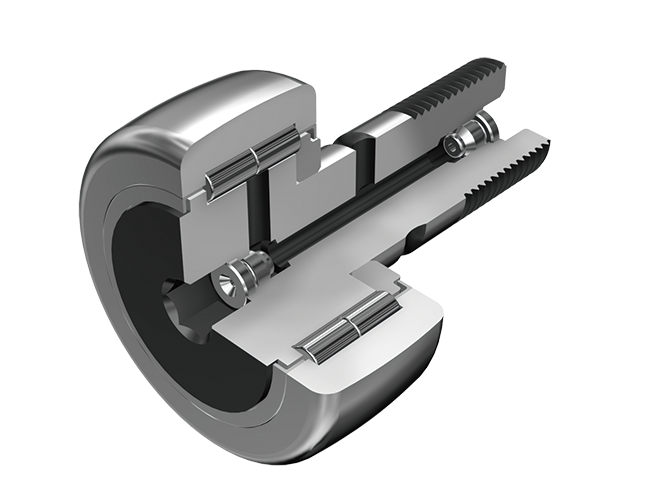

The cam follower is a compact and highly rigid bearing with a shaft. It contains needle rollers and is used as a guide roller for cam mechanisms or straight motion.

Since its outer ring rotates while keeping direct contact with the mating surface, this product is thick-walled and designed to bear an impact load.

Inside the outer ring, needle rollers with precision cages are incorporated. This prevents the product from skewing and achieves superb rotation performance. As a result, the product is capable of easily withstanding high-speed rotation.

There are two types of the outer ring shape: spherical and cylindrical. The spherical outer ring easily absorbs distortion of the shaft center when the cam follower is installed and helps lighten unbalanced loads.

The cam follower is used in a wide range of applications such as the cam mechanisms of automatic and dedicated machines, as well as transfer equipment, conveyors, bookbinding machines, tool changers of machining centers, pallet changers, automatic coating machines, and sliding forks in automated warehouses.

Types

Highlight feature tags

- Eccentric

- Popular type

- Containing thrust balls

- Tapped greasing hole

- Outer-ring compact type

- Easy-mount

- Double-row cylindrical

- Popular type

Stud diameter (mm) : 3,4,5,6,8,10,12,16,18,20,24,30

- Eccentric

Stud diameter (mm) : 5,6,8,10,12,16,18,20,24,30

- Containing thrust balls

Stud diameter (mm) : 5,6,8,10,12

- Tapped greasing hole

Stud diameter (mm) : 6,8,10,12,16,18,20,24,30

- Outer-ring compact type

Stud diameter (mm) : 2.5,3,4,5,6

- Easy-mount

Stud diameter (mm) : 6,8,10,12,16,18,20

- Double-row cylindrical

Stud diameter (mm) : 16,18,20,24,30

Features

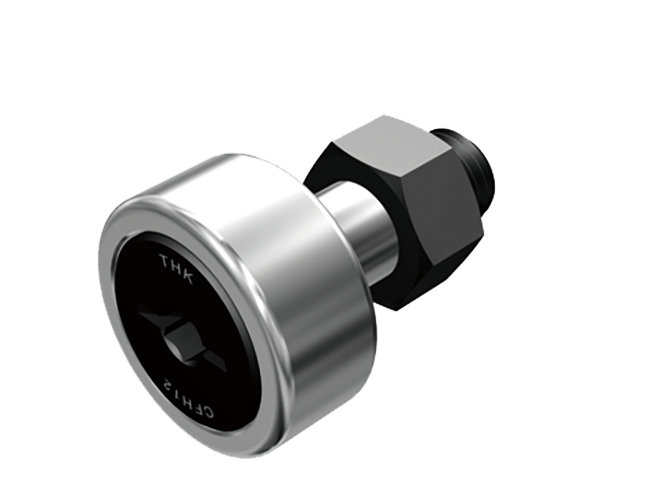

Structure and Features

The Cam Follower is a compact and highly rigid bearing with a shaft. It contains needle rollers and is used as a guide roller for cam mechanisms or straight motion. Since its outer ring rotates while keeping direct contact with the mating surface, this product is thickwalled and designed to bear an impact load. Inside the outer ring, needle rollers and a precision cage are incorporated. This prevents the product from skewing and achieves a superb rotation performance. And, as a result, the product is capable of easily withstanding high-speed rotation. There are two types of the outer ring in shape: spherical and cylindrical. The spherical outer ring easily absorbs a distortion of the shaft center when the cam follower is installed and helps lighten a biased load. The Cam Follower is used in a wide range of applications such as cam mechanisms of automatic machines, dedicated machines as well as carrier systems, conveyors, bookbinding machines, tool changers of machining centers, pallet changers, automatic coating machines, and sliding forks of automatic warehouses.

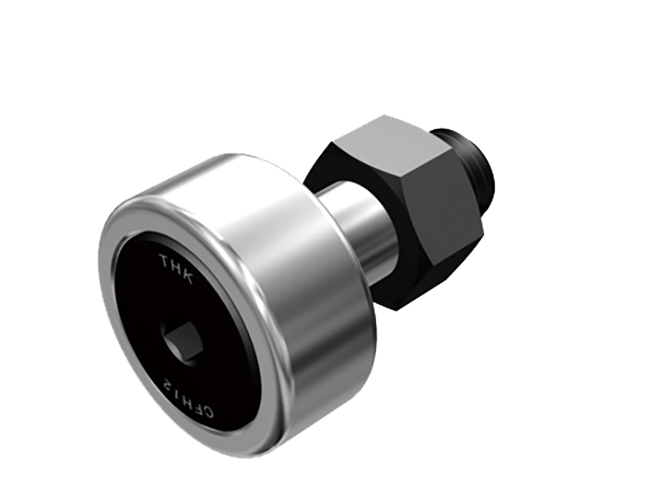

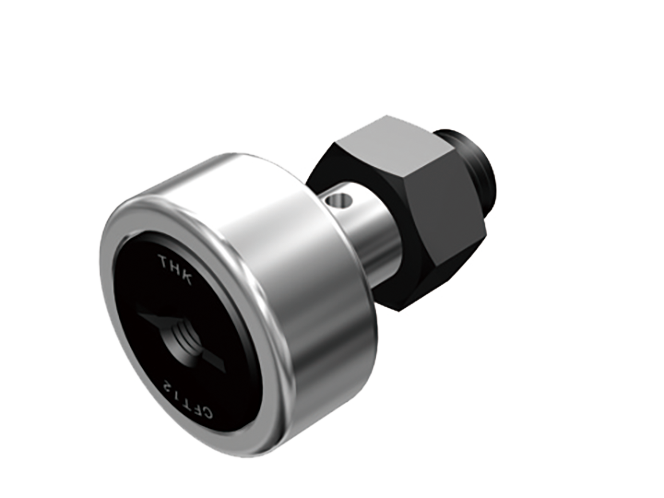

Cam Follower with Grease Nipple

With previous models it was necessary to fabricate a jig in order to install a plug or grease nipple.The Model CF-AB Cam Follower with grease nipples comes equipped with grease nipples on both sides, so it can be used immediately, without modification. An Allen wrench can be used to anchor the stud from either the head or the threaded end, and it can be lubricated from either end as well. This ensures that there will be adequate space to install the unit and perform maintenance, improving work efficiency.

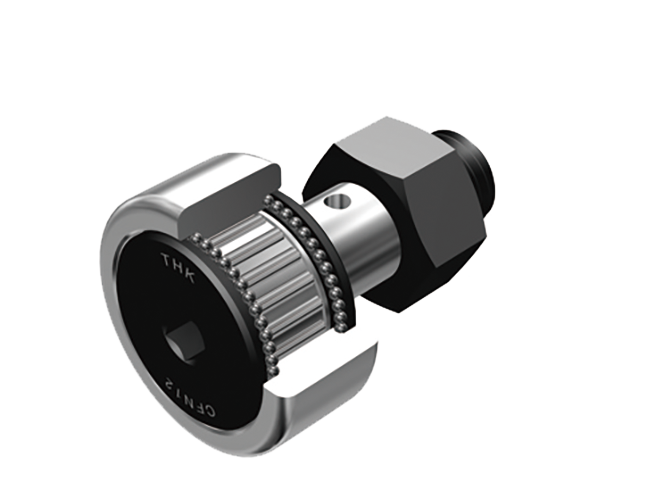

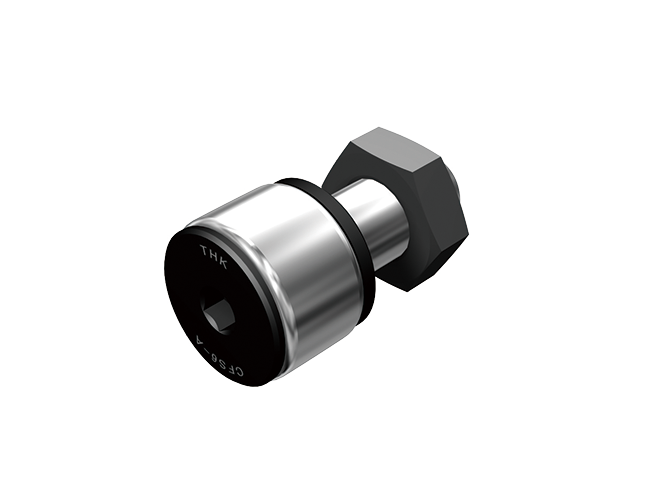

Cam Follower Containing Thrust Balls

Even a slight mounting error in a high speed cam mechanism operating in a harsh environment could cause abnormal wear to the thrust unit of the cam follower. In such a case, using Cam Follower Containing Thrust Balls model CFN will bring about a significant effect in increasing the durability. Models CFN5 to 12 are standard-stock items. If desiring a size other than the standard items, contact THK. Model CFN is capable of receiving a thrust load caused by a slight mounting error. However, it is necessary to minimize a component of thrust force, or prevent it from occurring, when designing the cam mechanism and installing the Cam Follower.