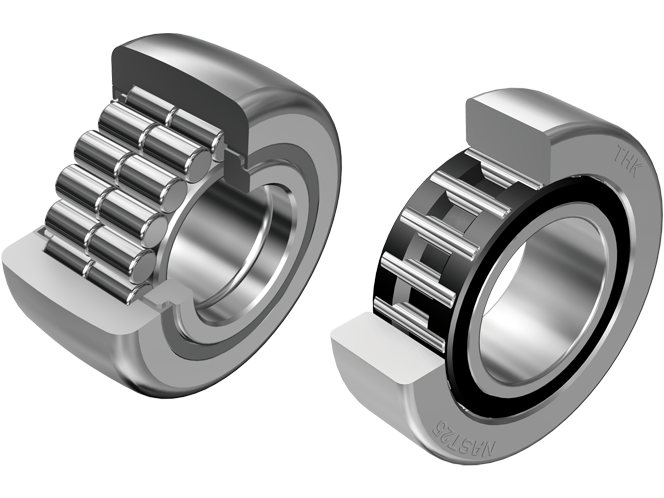

The roller follower is a compact and highly rigid bearing system. It contains needle bearings and is used as a guide roller for cam plates or linear motion.

Since its outer ring rotates while keeping direct contact with the mating surface, this product is thick-walled and designed to bear impact loads.

Inside the outer ring, needle rollers with precision cages are incorporated. This prevents the product from skewing and achieves superb rotation performance. As a result, the product is capable of easily withstanding high-speed rotation.

Roller followers are divided into two types: a separable type whose inner and outer rings can be separated, and a non-separable type whose inner and outer rings cannot be separated.

There are two types of the outer ring shape: spherical and cylindrical. The spherical outer ring easily absorbs distortion of the shaft center when the cam follower is installed and helps lighten unbalanced loads.

The roller follower is used in a wide range of applications such as cam mechanisms of automatic and dedicated machines, as well as transfer equipment, conveyors, bookbinding machines, tool changers in machining centers, pallet changers, automatic coating machines, and sliding forks in automated warehouses.