Nov 1, 2023

Products

Examining the Workings of the Linear Motor through Its Features and Applications

The Japanese manufacturing industry is struggling with a declining labor population due to the country's aging society and declining birthrate, and the problem is intensifying. According to one survey, the working age population (ages 16 to 64) in Japan is expected to be 14 million people fewer in 2030 than it is today. If nothing changes, it's clear that the labor shortages are going to accelerate, which will hurt the Japanese economy. Factory automation (FA) will be an essential method of achieving labor savings to solve the challenges facing the manufacturing industry. Within this field, a particular challenge is how to boost the productivity of semiconductor manufacturing and inspection equipment, machines that produce automotive parts, and rechargeable battery manufacturing equipment.

In this article, we’ll take a look at the linear motor, which is expected to be increasingly used for productivity improvements in factory automation; variable-mix, variable-volume production; and flexible manufacturing. One example of a linear motor is Japan Railway's linear Chuo Shinkansen, which is a maglev train that uses superconducting magnets. The linear motors used in FA employ a different method, but the characteristics are the same. We'll examine the types of benefits that these linear motors bring to the world of FA and introduce the linear motor system that THK offers.

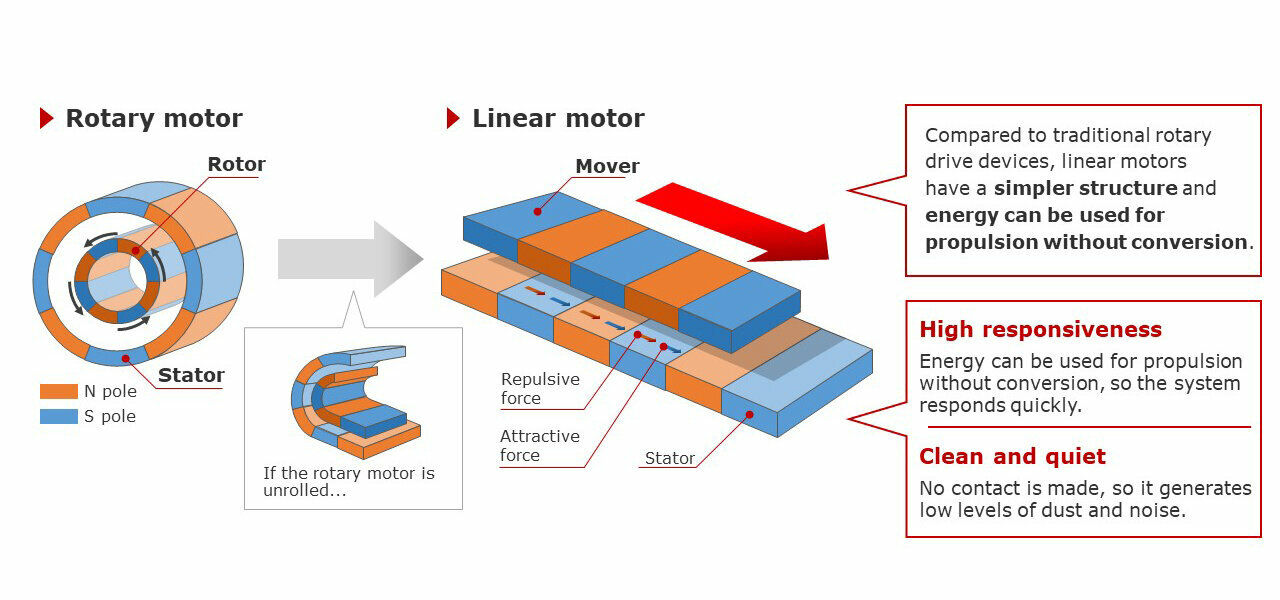

Linear Motors Are Unrolled Versions of Rotary Motors

Linear motors have the same structure as if a typical rotary motor were unrolled, so the north and south poles of the magnets alternate in a straight line. Running a current through the linear motor coil will create alternating magnetic fields, generating a straight driving force through repulsion and attraction.

Benefits of Using a Linear Motor Drive

Linear motors have recently seen use in a variety of machinery and industries, including semiconductor and rechargeable battery manufacturing equipment, automotive component assembly processes, and transfer devices. Linear motors offer the following advantages over drive systems that rely on ball screws or other similar machine elements.

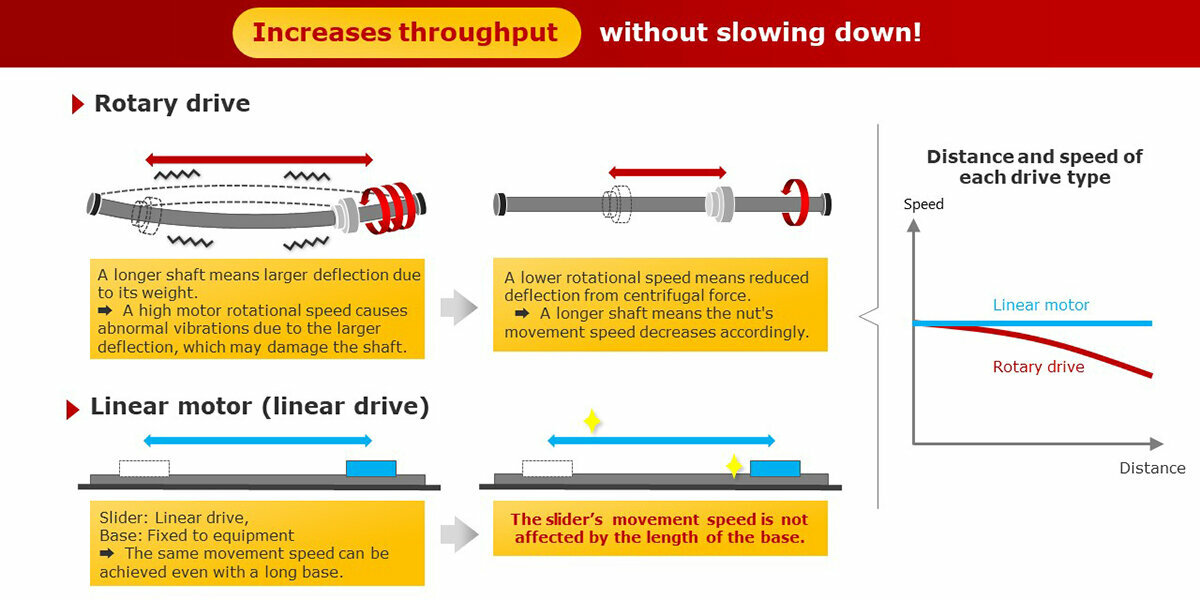

1. High-speed movement

The speed of a ball screw drive is limited by the DN value and the critical speed (the normal mode of the screw shaft). In particular, the stroke can make it difficult to increase the speed. Linear motors don’t face these restrictions, so they enable high-speed motion even over long strokes.

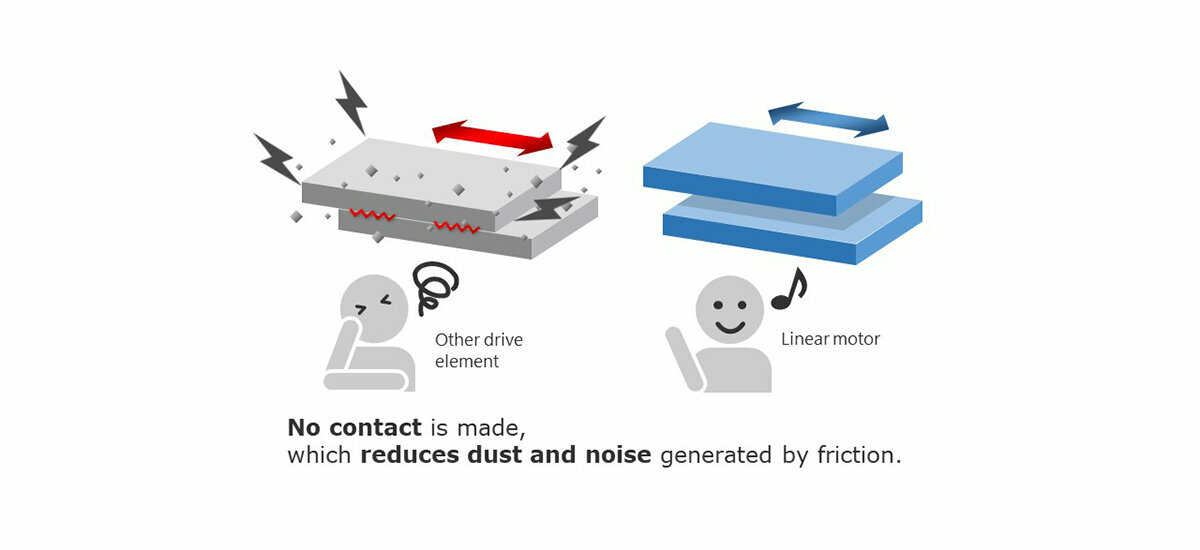

2. Low noise, vibration, and dust generation

Thrust is generated through a contactless drive structure, so there is no vibration caused by the rotation of a ball screw or the recirculation of rolling elements. As a result, this product produces low levels of noise and vibration. In addition, there's no problem with grease scattering about, which is a concern with ball screws.

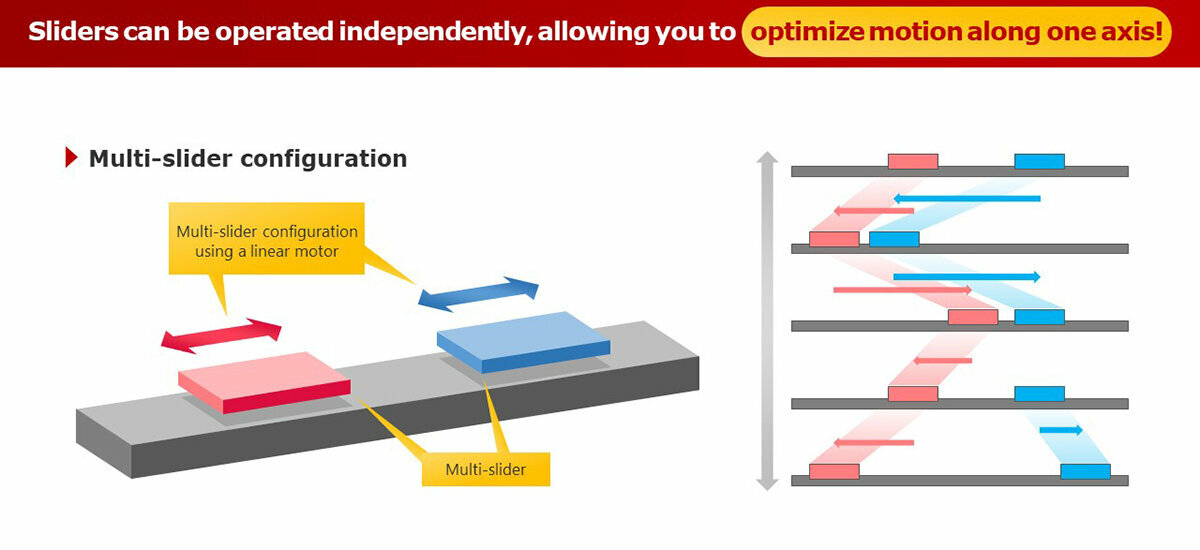

3. Compatible with multiple sliders

Multiple sliders can be set on a single-axis base and controlled individually. For instance, even six different sliders could be set on a single-axis base, and all six could be operated independently.

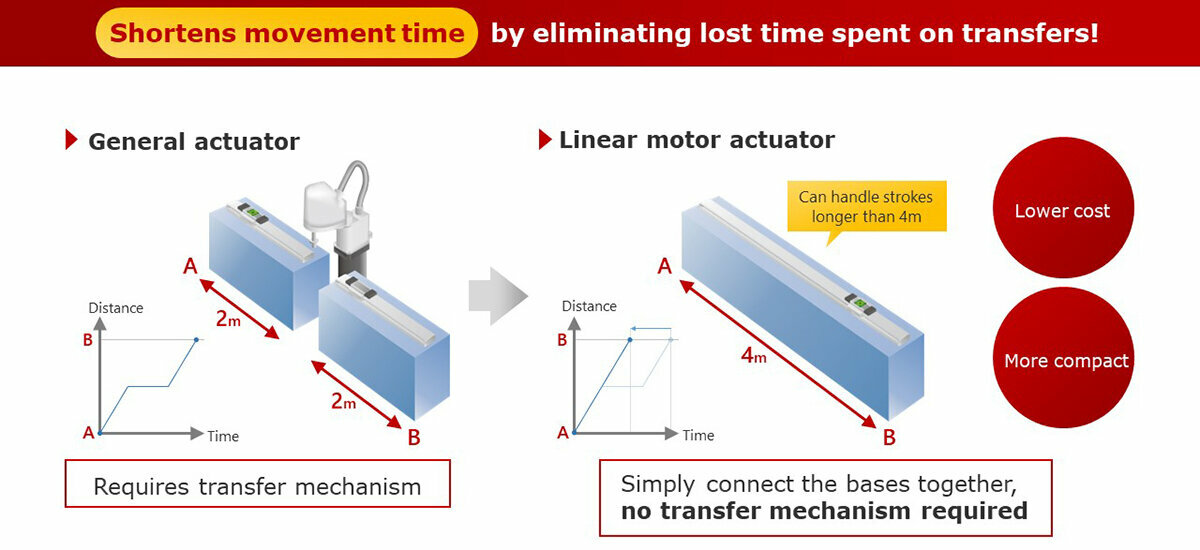

4. Long stroke

The linear motor can also handle long strokes by connecting magnets together. (*A sensor/linear encoder is required to detect the stroke positions.)

They can even be connected to form a stroke that exceeds 2 m in length.

We’ve even handled requests for strokes that are dozens of meters long.

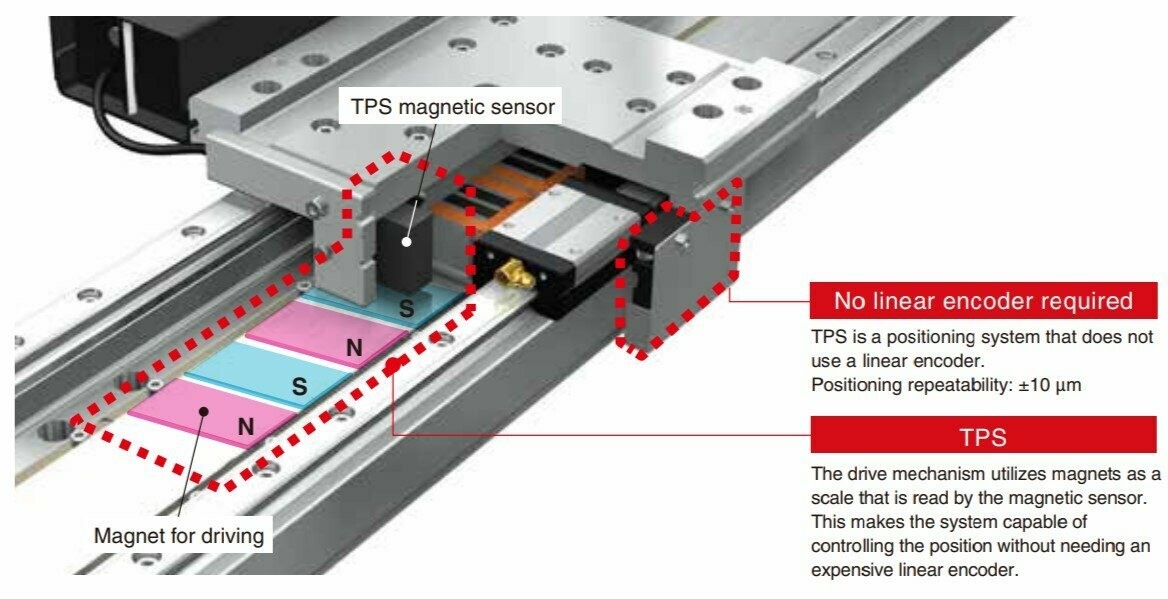

THK’s Scaleless Linear Motor System

The scaleless linear motor system uses a magnetic sensor to read the driving magnets as a scale , with no need for a linear encoder to detect the position. This lowers the product’s cost by an amount equal to the linear encoder that isn't used. In turn, this means that the product can be used in a wide variety of transfer applications that have been constructed with traditional rack and pinion or belt drive mechanisms. In particular, the lack of a scale means that it’s easy to use for transfer applications over long distances simply by connecting the LM Guide units and bases. This modularization also reduces design and assembly time.

We hope you consider adopting the scaleless linear motor system for a number of applications. Please contact us if you require absolute (high-precision) specifications.

Contact information

THK LM SYSTEM Pte. Ltd.

38 Kaki Bukit Place LM Techno Building Singapore 416216

Tel: +65-6884-5500 / Fax:+65-6884-5550

E-Mail:sales@thksg.com