Jun 21, 2023

Products

The Indispensable Ball Joint for Vehicle Suspension Systems

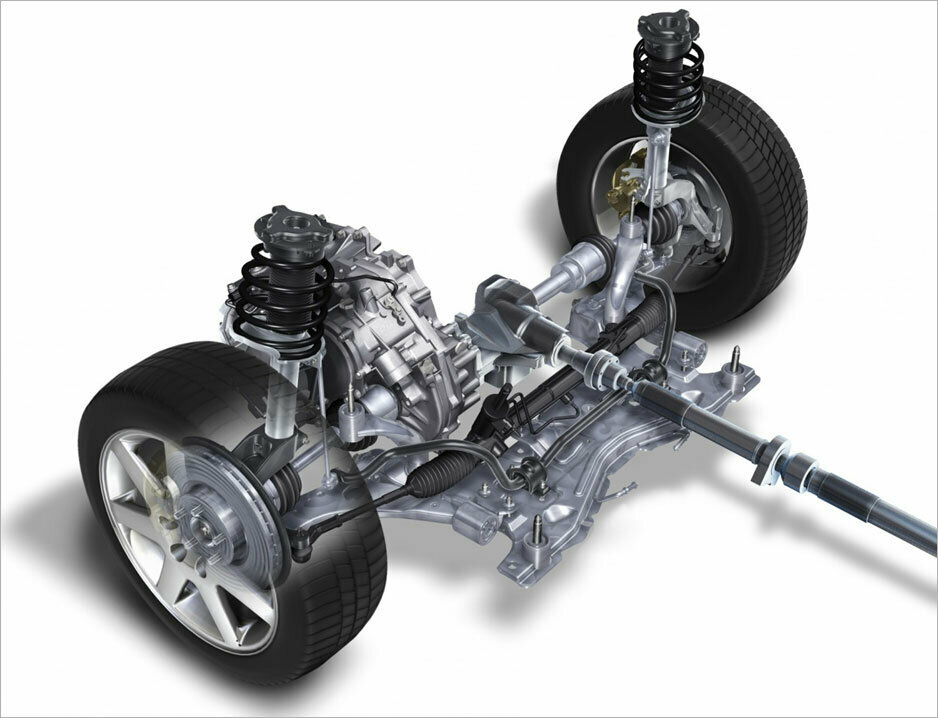

What is known by car enthusiasts as the suspension is a collection of critical components around the tires that influence steering wheel control and the riding experience. The components that join the body of the vehicle with the tires serve a number of functions, such as accurately transmitting the movement of the steering wheel and determining the riding experience for those sitting in the driver’s, passenger’s, and rear seats. In this article, we’ll introduce the suspension component known as the ball joint.

Ball Joints Divided by Function and Application

THK, known best for its linear motion guides, also develops, manufactures, and sells ball joint products used in various automotive applications, such as passenger cars, trucks, motorcycles, ATVs (four-wheel buggies), heavy machinery, and agricultural machinery.

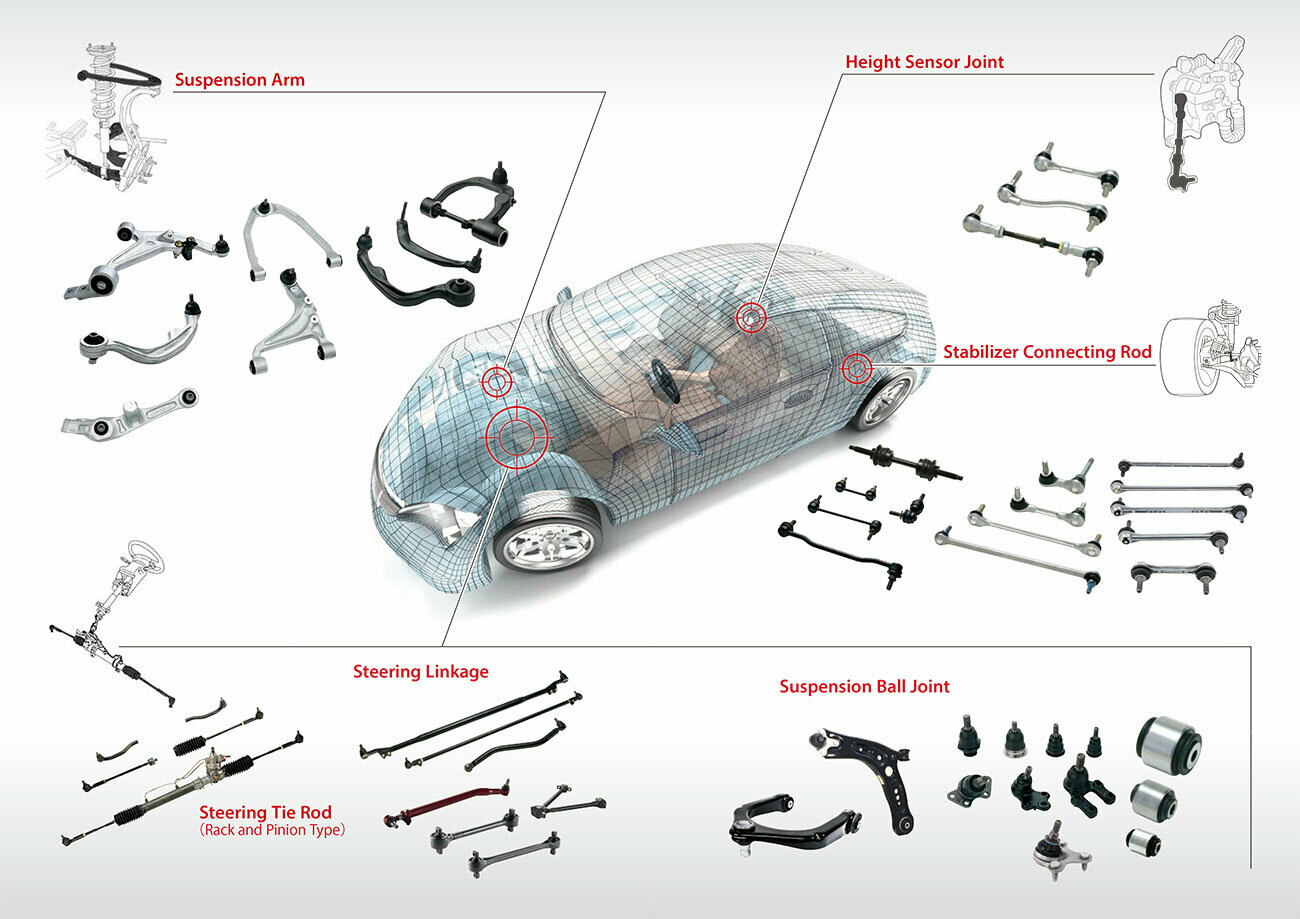

Our mainstay linkage and suspension products are divided into the three categories below based on their functions and applications.

- Small joint components installed onto products that connect transmission wires and detect vehicle position in combination with sensors

- Suspension ball joints that join together components around the vehicle’s tires to maintain their proper orientation for vehicle performance and safety, as well as link components that combine suspension arms and joints

- Tie rod end ball joints that are indispensable for transferring steering input to the knuckle when the vehicle turns

Joints are Crucial for Full Use of Physical Abilities and Athletic Performance

Considering that our joints enable the use of such exceptional physical prowess as that possessed by a baseball player who pitches a fast ball that can break a bat, a figure skater striking an exquisite pose, or a long-distance marathon runner, any damage to the body’s joints has a tremendous impact.

When something is wrong with a person’s joints, they lose their overall balance and are unable to use their full strength. The same is true for a vehicle’s joint components. Recent cars show significant technological developments in pursuit of CASE and MaaS, but so long as vehicles drive on the ground, these components will be indispensable, and every year, performance requirements such as range of motion, torque, durability, and environmental impact become more stringent as a result of the transition to self-driving vehicles and BEVs.

In addition to over 50 years of experience with automotive joint components, THK also has the know-how built up around joint components used in industrial equipment, construction machinery, agricultural machinery, and specialty vehicles.

We continue to propose robust designs to meet the strength, durability, and environmental resistance requirements of our customers.

Ball Joints with Reliable Performance in Any Environment

While joint components are designed differently for different vehicles, the joints installed on a given vehicle are the same whether it is driven in a searing desert or the extreme cold of snowy climes, on the paved city streets or bumpy, muddy mountain roads.

THK's joint components naturally and reliably provide the necessary performance in various environments around the world, giving drivers peace of mind. Although these parts often go unseen by the average driver, and advancements and quality are largely intangible, this technology continues to offer support from behind the scenes.

Uniform Performance and Quality for Customers around the World

THK designs these components alongside customers from around the world at its product development centers in Japan, Germany, and Canada. In addition, we produce them at plants in various countries in Asia, Europe, and North and Central America, which means that we can offer ball joint components with consistent performance and quality to meet our customers' needs. Having met the strict requirements of customers from around the world for many years, THK has received much acclaim and has become top class in the world in terms of its global sales share in the field.

The ball joint is indispensable for vehicle suspensions. An additional feature of THK's ball joint is the fact that it has been used for industrial machinery as well as automotive applications. Furthermore, our integrated production and sales structure ensures that quality control and supply stability are tightly maintained along with product performance, allowing a range of customers to use these components with peace of mind.

Please contact THK's Automotive & Transportation Headquarters for inquiries regarding ball joint products.

* To access the catalog, you must create a free account on THK Online Services.

Contact information

THK LM SYSTEM Pte. Ltd.

38 Kaki Bukit Place LM Techno Building Singapore 416216

Tel: +65-6884-5500 / Fax:+65-6884-5550

E-Mail:sales@thksg.com