Jun 26, 2024

Products

Slide Rails Supporting Logistics Warehouse Automation and the Adoption of Robot Technology

Not a day goes by that we don’t hear news about work-life balance, the 2024 problem in the logistics and construction industries, and various industries bemoaning labor shortages. Businesses have lately taken to instituting overtime, creating part-time positions, and utilizing temporary workers to shore up their labor forces. At the same time, however, drastic increases in labor costs and energy prices create strong headwinds against profitability. As a result, it has become imperative for each industry to increase productivity, rendering the push for work automation essential. In this article, we’ll look at the utility slide, a slide rail that is used to solve these challenges in a variety of applications, such as automation equipment for logistics.

Where Should I Start?

When the word “automation” comes up, a lot of people are probably uncertain where they should start. Reducing staffing and transferring excess labor to more productive work functions is indispensable for increasing productivity and improving efficiency. In addition, the difficulty, time, and cost associated with the technology required for reducing human intervention vary greatly. That is why we recommend devices that are easy to implement and expected to be highly effective.

Logistics Automation Is Optimal for Increasing Productivity

Everyone has probably ordered something online from an e-commerce company or a mass market retailer. We’ve come to take it for granted that, as long as you place your order by a certain time, your package will arrive the next day. But having human workers pick products one by one from stock shelves would require an extraordinary amount of labor. If the warehouse is automated, however, carts carry packages composed of multiple products picked from stock shelves when those packages are to be shipped. This drastically reduces the burden on workers and makes it possible to reduce staffing.

Automation that maximizes the utilization of human labor is indispensable for supporting the conveniences the world enjoys. For its part, THK's Utility Slide Model ATG is used for the cart arms that pull containers from shelves in the automated warehouses where this is happening.

What Is a Utility Slide?

A utility slide is a type of slide rail that has high load capacity and high durability.

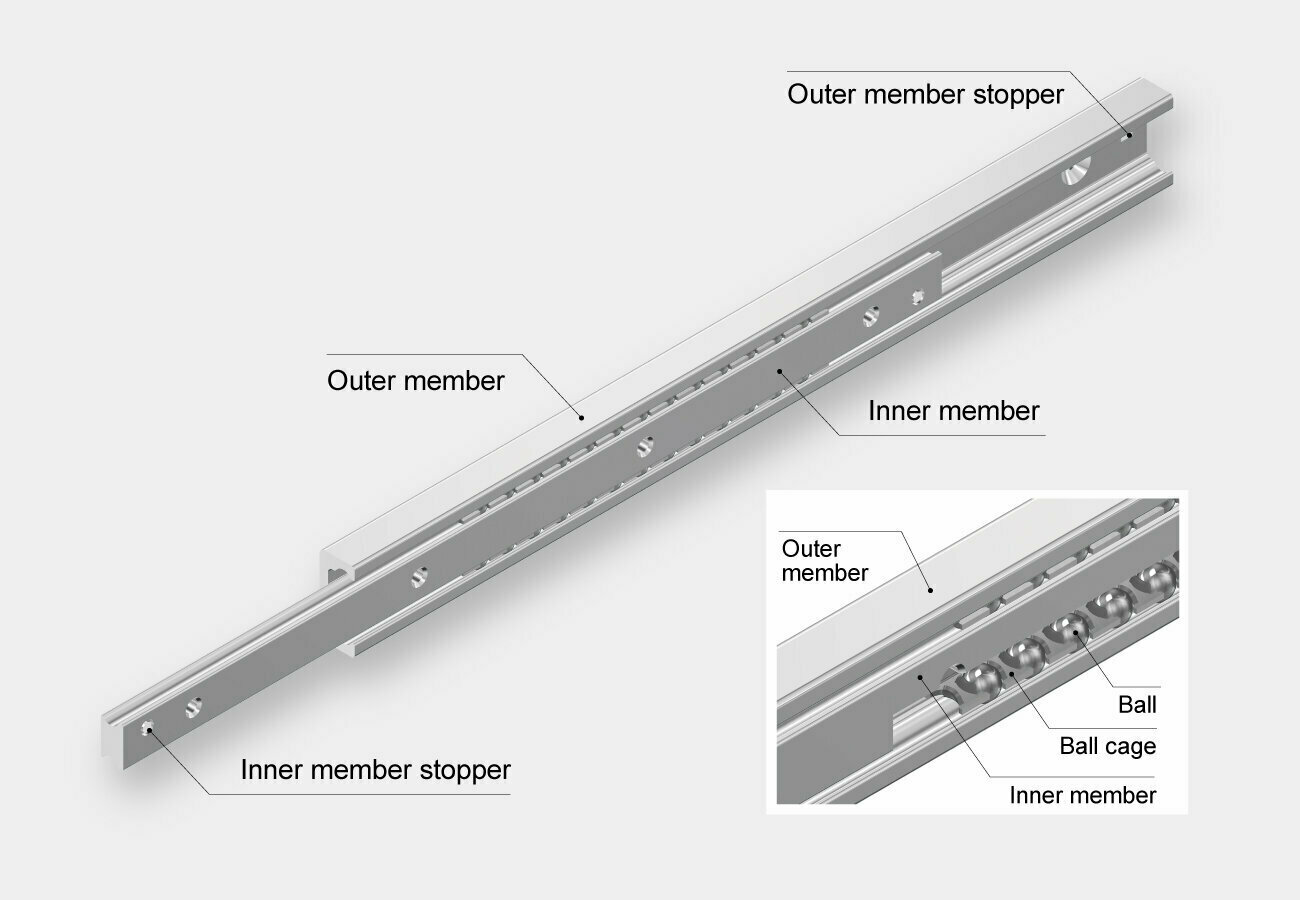

The Utility Slide Model ATG developed by THK is composed of an outer member (outer rail), an inner member (inner rail), balls, and a ball cage (retainer). It makes use of high-carbon steel and an optimized lubricant (lithium-based AFT-LF Grease), both cultivated for THK’s core linear guide technology.

The ATG is a telescopic slide rail with inner and outer members that expand and collapse, and it possesses a high load capacity and superior durability. Its two rows of balls enable smooth, stable movement, and it can also be mounted with an ease unique to slide rails.

The three principal features of the ATG are highlighted below.

1. Improved permissible load and extended service life

The Model ATG distinguishes itself from conventional slide rails by incorporating the same high-carbon steel used in the LM Guide for its inner member and by having raceway grooves with surfaces hardened and strengthened by induction. Because of this, it can handle loads greater than 10 times what is possible with conventional slide rails, which are made of sheet metal. All of this contributes to high durability, improved permissible load, and an extended service life.

2. Ease of mounting

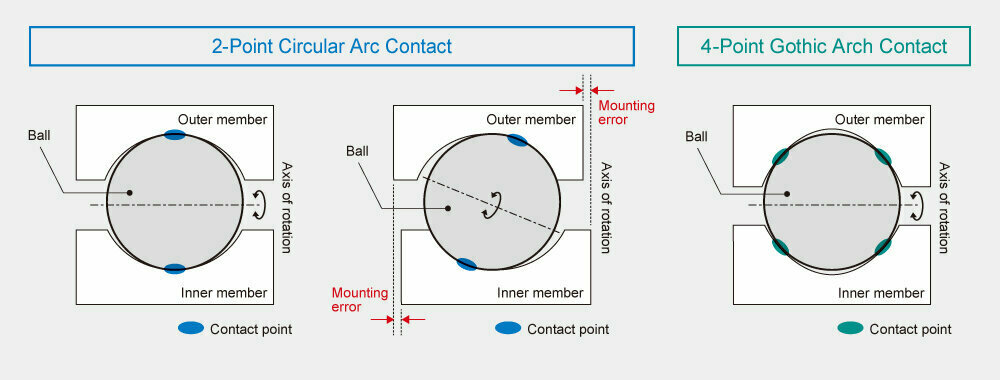

As mentioned above, the linear motion mechanisms used for shuttles (carts) in automated warehouses are often mounted directly onto the rough surfaces of aluminum frames, which requires that they be capable of absorbing mounting error. To achieve this, the Model ATG uses circular arc grooves with two-point contact that have the ability to absorb any mounting errors by shifting the points where the balls contact the groove. It thus excels at adjusting to slight inaccuracies in the mounting surface during installation, making these adjustments easy. Mounting can be done without the oversight of an engineering specialist, which can reduce on-site workload and work time. This, in turn, contributes to increased productivity at logistics warehouses.

Circular arc grooves have the ability to absorb any mounting errors by shifting the point where the balls contact the groove.

3. Helps prevent locking at the stroke end

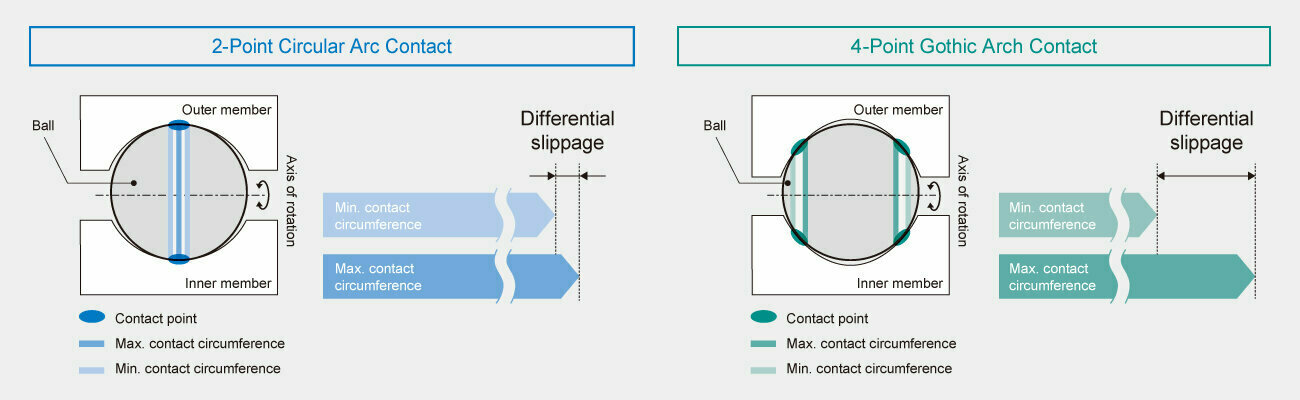

In contrast to the Gothic-arch grooves used by conventional products, the circular arc grooves of the Model ATG have low differential slip between balls and suppress ball misalignment thanks to the balls only making contact with rail raceway grooves at their deepest interior points. This in turn makes it possible to prevent locking at the stroke end, which is caused by ball misalignment, and contributes to the stable running of equipment.

Example applications beyond logistics warehouses

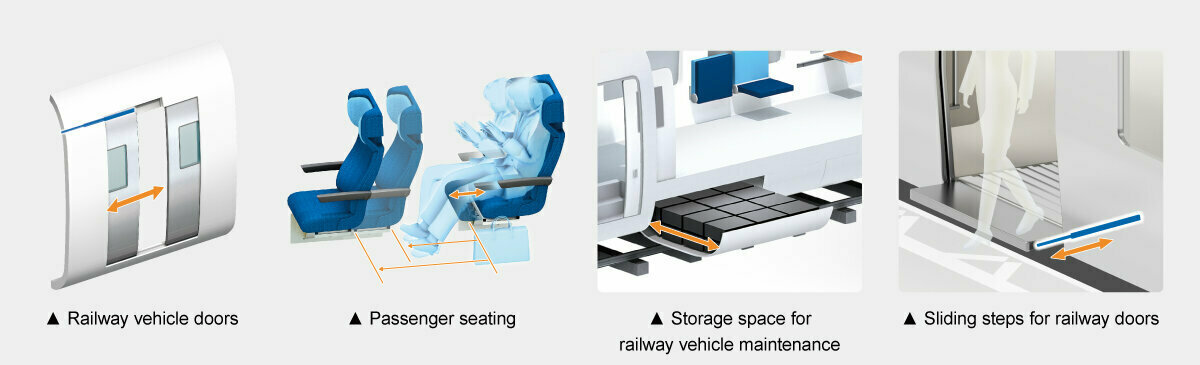

The Utility Slide Model ATG can be incorporated into a variety of other products as well through combination. Let’s look at some examples.

- Railway vehicle door guides

- Machine tool door guides

- Seat sliders

- Battery maintenance door pull-outs

- Railway vehicle door step sliders

- Workpiece stocker guides

The mounting surfaces on these products aren’t likely to have a high degree of accuracy. In light of this, the Model ATG ultimately reduces overall costs by eliminating additional processing costs and shortening installation time. If you are concerned about the accuracy and machining of surfaces for guide rail installation, please contact THK.

Contact information

THK LM SYSTEM Pte. Ltd.

38 Kaki Bukit Place LM Techno Building Singapore 416216

Tel: +65-6884-5500 / Fax:+65-6884-5550

E-Mail:sales@thksg.com