Sep 27, 2023

Dec 11, 2025

Products

Non-Magnetic and Extremely Corrosion-Resistant! A Closer Look at Products Contributing to Cutting-Edge Science

Non-magnetic materials are not attracted to magnets and have special properties that prevent magnetic fields from forming. (Materials with low levels of magnetism can also be referred to as non-magnetic.)

Industrial materials with these properties include stainless steel and aluminum alloys, but the intensifying requirements for special environments in cutting-edge scientific fields in recent years have created a need for non-magnetic products with even higher levels of performance. Let’s take a look at THK's revolutionary products that offer high performance, non-magnetic properties, and superior corrosion resistance.

Non-Magnetic Products Born from Needs Caused by Scientific and Technological Advances

Looking across various fields, most of the latest technology is made possible through the achievement of special environments that generally do not exist anywhere else. THK’s high-performance, non-magnetic, and extremely corrosion-resistant products are designed for use in such special environments.

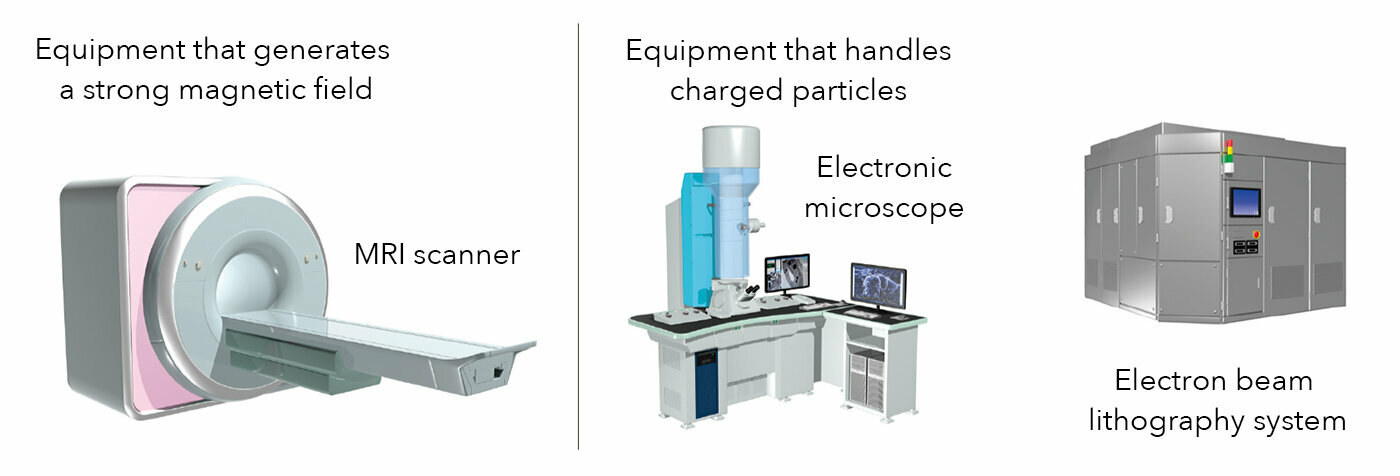

To give one example, non-magnetic products are required for technologies such as thermonuclear fusion reactors, which are one part of the uncharted frontier of science and technology that has been garnering attention recently. Thermonuclear fusion reactors utilize powerful electromagnets, which means that structures around them must be non-magnetic to prevent them from being pulled in and breaking due to the strong magnetic force. This is an environment where non-magnetic products are perfectly suited for use.

As hydrogen is controlled in a plasma state by a superconducting magnet (the highlighted portion), the surrounding components all need to be composed of non-magnetic materials.

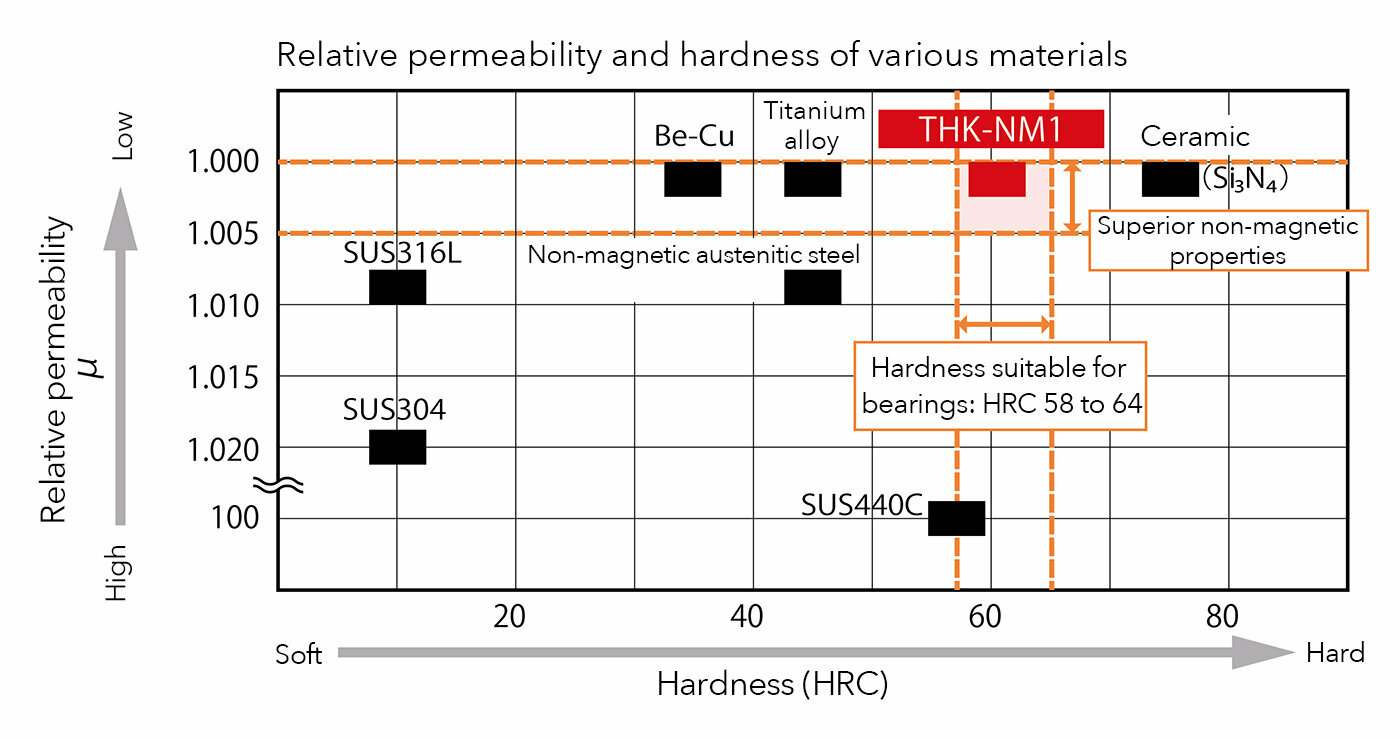

Another example where non-magnetic products are used is the semiconductor manufacturing process. Cutting-edge semiconductors get smaller every year, and next-generation units are said to have circuits as narrow as 2 nm (1 nanometer is 1/1,000,000 of a millimeter). These microscopic circuits are precisely drawn onto a glass plate (photomask) by an electron beam from a mask writer, a device used in semiconductor manufacturing. However, the nature of the electron beam makes it so that even the slightest magnetic force will cause bending. In order to draw microscopic circuit patterns accurately, the most important thing is to ensure the beam travels straight. That means that all of the components near the path where the electron beam will travel must be non-magnetic to an extremely high degree (with a relative permeability* roughly equal to 1.001). THK's non-magnetic products have demonstrated their true worth even in this kind of extremely precise field.

* Relative permeability is an indicator of how much an object resists magnetization.

THK-NM1 is a special alloy that was originally researched in a THK laboratory as a new material to be used in high-performance, non-magnetic, and extremely corrosion-resistant products. One day, a cutting-edge semiconductor manufacturing equipment maker ordered a prototype from us with very strict non-magnetic requirements, and we ended up trying out this material. That resulted in an extremely favorable reaction from the customer, and we were convinced that this material would be recognized in the market as a solution for customers looking for a non-magnetic product. There were still some uncertainties as far as the material itself was concerned, but we felt strongly that bringing it to market and having it utilized would contribute to society, so we decided to first make it available upon request.

A Special Alloy Material That Makes High-Performance Non-magnetic Products a Reality

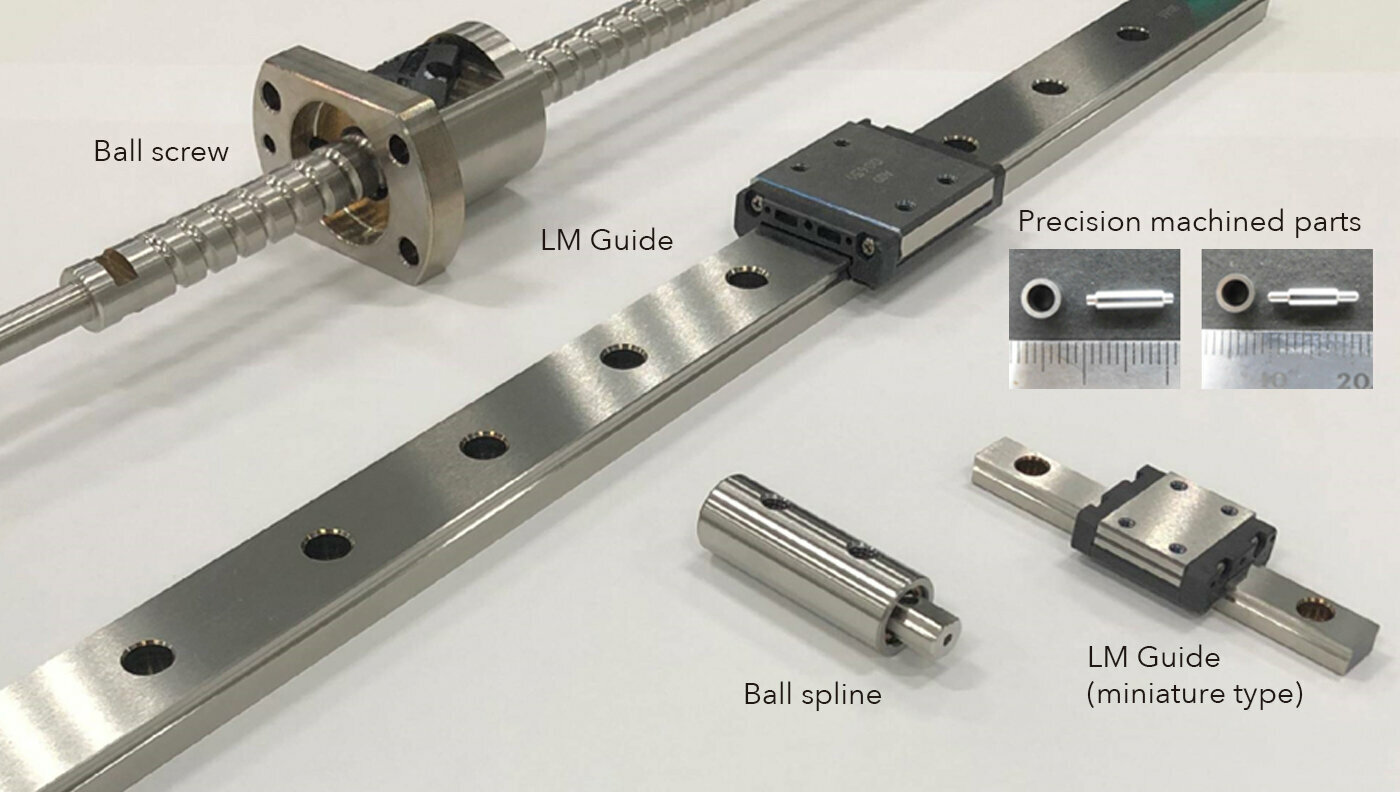

THK's high-performance, non-magnetic, and extremely corrosion-resistant products utilize the aforementioned THK-NM1, a nickel alloy that is non-magnetic and also possesses high corrosion resistance, for the main metal components. Customers can also select the materials for other auxiliary parts based on their needs, allowing us to deliver products complete with the components that provide the perfect balance for the customer’s required specifications.

Another area where THK-NM1 excels is its increased hardness. Conventional non-magnetic materials and materials with high corrosion resistance traditionally have low hardness and generally only reach around 40 HRC even when heat-treated. However, THK-NM1 is able to achieve around 60 HRC. This is consistent with the optimal hardness of 58 to 64 HRC for use with bearings, and a higher hardness means that rolling guides like the LM Guide can support a larger load. This enables customers to achieve a significantly more compact machine design compared to softer traditional materials, which contributes to an increase in productivity relative to space.

Excelling in Both Non-magnetic Properties and Corrosion Resistance

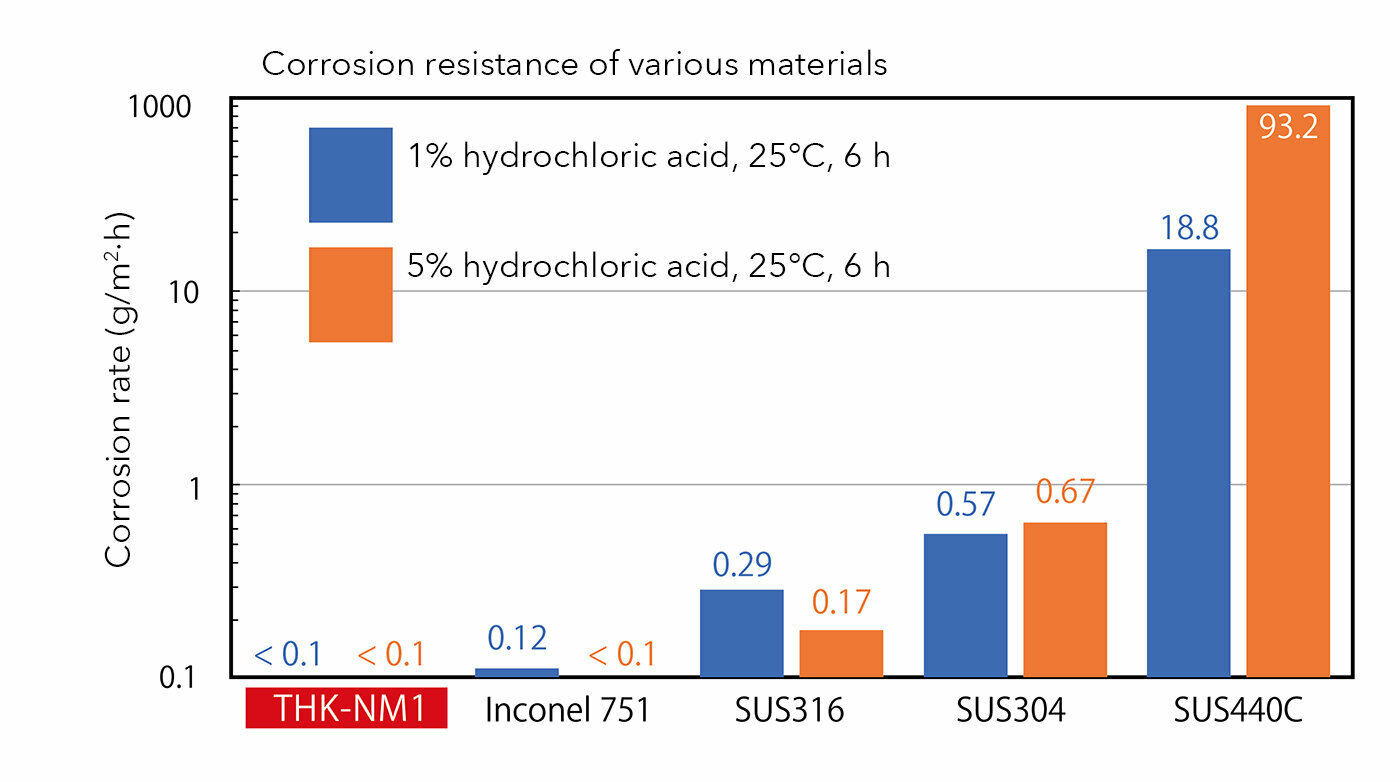

High-performance, non-magnetic, and extremely corrosion-resistant products are created for use in special environments, and they possess both a very high standard of non-magnetism and a corrosion resistance strong enough to be referred to as “extreme.” These products can be used in special environments that weren’t sufficiently covered by conventional products in cutting-edge scientific fields, such as semiconductor manufacturing equipment and other devices that handle charged particles, generate strong magnetic fields, or use highly corrosive chemicals.

Features of Products That Use THK-NM1 as the Main Material (Non-magnetic Properties)

- Very high standard of non-magnetism

- Superior load capacity thanks to high hardness

- Smooth, precise motion thanks to possessing optimal hardness for bearings

Features of Products That Use THK-NM1 as the Main Material (Corrosion Resistance)

- Extremely high corrosion resistance against many chemicals

- No surface treatment means no fears of flaking (corrosion resistance is maintained even when wear occurs)

- Significant reduction of maintenance burden due to corrosion

From Cutting-Edge Scientific Fields to Everyday Devices

Up to now, the main applications of this technology have largely been in semiconductor manufacturing equipment. More specific examples include electron beam lithography systems and electron beam measuring equipment as non-magnetic applications, and wafer washing equipment as a highly corrosion-resistant application. Besides these uses, this material can be employed in precision analyzers such as electron microscopes and MRI systems. As it can also be utilized in medical devices and food machinery that is frequently sterilized and disinfected, we expect that its use will range from cutting-edge scientific equipment to devices that are relatively familiar to all of us.

The Powerful Advantage of High-Performance, Non-magnetic, and Extremely Corrosion-Resistant Products

We sometimes receive questions from customers concerning the non-magnetic properties and corrosion resistance, such as “What is the actual non-magnetic performance like?” and “Will it really not corrode even with the chemicals we use?” To address these kinds of questions, we have prepared a large quantity of product samples and material cut samples. We believe that providing these samples to customers will allow them to directly experience the material's high level of performance. Up to now, our material has never once failed the test, which reinforces our confidence in the superiority of these products.

Helping to Build a Sustainable Society

As mentioned earlier, the main applications of this material so far have been in a variety of equipment in cutting-edge scientific fields, and we expect to broaden and deepen our expansion into the market. By furthering our recognition in the special environment market, we aim to contribute to the creation of a sustainable society, which is a challenge that we hold in common with the field of cutting-edge science.

* To access the catalog, you must create a free account on THK Online Services.

Contact information

THK LM SYSTEM Pte. Ltd.

38 Kaki Bukit Place LM Techno Building Singapore 416216

Tel: +65-6884-5500 / Fax:+65-6884-5550

E-Mail:sales@thksg.com