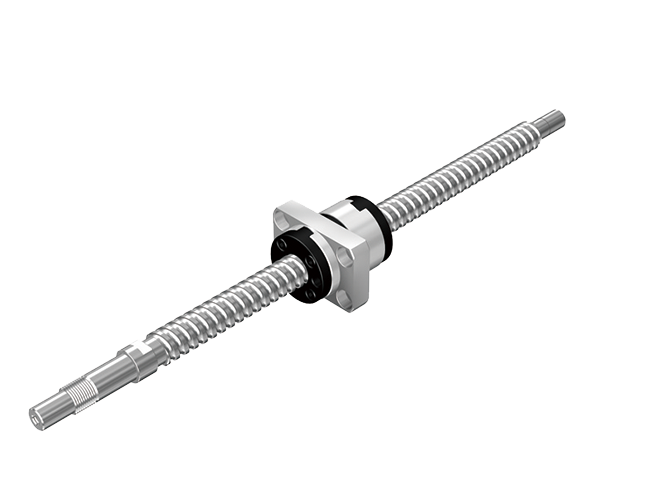

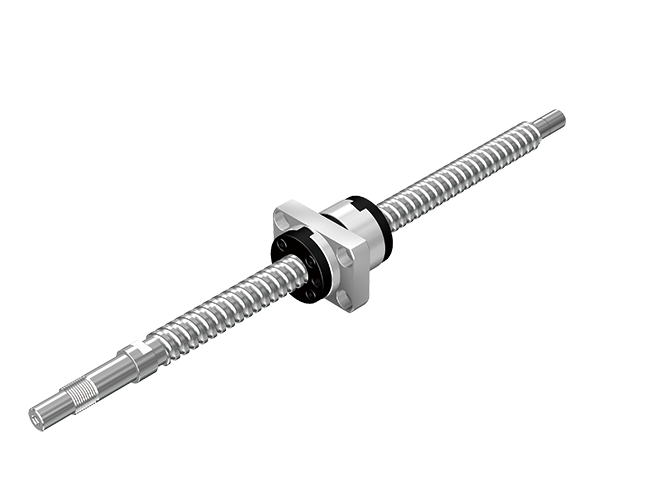

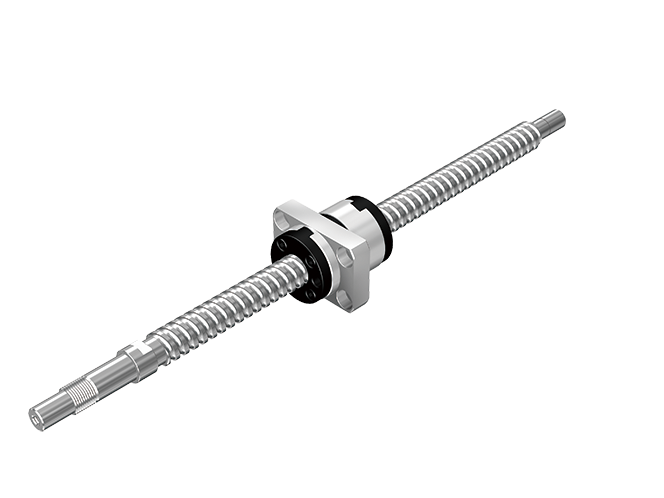

BNK Precision Ball Screw with Finished Shaft Ends

To meet space-saving requirements, this type of ball screw has a standardized screw shaft and a ball screw nut. The ends of the screw shaft are standardized to fit the corresponding support unit. The shaft support method with Models BNK0401, 0501, and 0601 is "fixed-free," while other models use the "fixed-supported" method with the shaft directly coupled with the motor.

Screw shafts and nuts are compactly designed. When a support unit and a nut bracket are combined with a ball screw, the assembly can be mounted on your machine as it is. Thus, a high-precision feed mechanism can easily be achieved.

Types

Highlight feature tags

- Large lead

- Preload

- No preload

- End-cap type

- Deflector type

- Precision positioning (ball screw)

- Finished shaft ends

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

- Deflector type

Lead(mm) : 1

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

- Deflector type

Lead(mm) : 1

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

- Deflector type

Lead(mm) : 1,8

- Precision positioning (ball screw)

- Finished shaft ends

- Large lead

- Preload

- No preload

- End-cap type

- Deflector type

Lead(mm) : 1,2,10

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

Lead(mm) : 2,4,10

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

Lead(mm) : 2,5,8

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

Lead(mm) : 2,4,8

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

- End-cap type

Lead(mm) : 10,20

- Precision positioning (ball screw)

- Finished shaft ends

- Large lead

- Preload

- No preload

- End-cap type

Lead(mm) : 16

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

Lead(mm) : 10,20

- Precision positioning (ball screw)

- Finished shaft ends

- Preload

- No preload

- End-cap type

Lead(mm) : 20

Features

Features

To meet the space-saving requirement, this type of ball screw has a standardized screw shaft and a ball screw nut. The ends of the screw shaft are standardized to fit the corresponding support unit. The shaft support method with Models BNK0401, 0501, and 0601 is "fixed-free," while other models use the "fixed-supported" method with the shaft directly coupled with the motor.

Screw shafts and nuts are compactly designed. When a support unit and a nut bracket are combined with a ball screw, the assembly can be mounted on your machine as it is. Thus, a high-precision feed mechanism can easily be achieved.

Contamination Protection and Lubrication

The ball screw nut is sealed with an appropriate amount of grease. In addition, the ball screw nuts of Model BNK0802 or higher contain a labyrinth seal (with Models BNK1510, BNK1520, BNK1616, BNK2020, and BNK2520, the end cap also serves as a labyrinth seal).

When the inflow of foreign material is possible, it is necessary to use a dust-prevention device (e.g. bellows) to completely cover the screw shaft.