Cross-Roller Ring Precautions on Use

Precautions on Use

Handling

- Please use at least two people to move any product weighing 20 kg or more, or use a dolly or another conveyance. Doing so may cause injury or damage.

- The inner and outer rings, which are comprised of two parts, are held together with a special rivet or screws, so install as is. Incorrect installation of the spacer retainer will greatly affect rotational performance, do not disassemble the Cross Roller Ring.

- Take care not to drop or strike the Cross Roller Ring. Doing so may cause injury or damage. Giving an impact to it could also cause damage to its function even if the product looks intact.

- When handling the product, wear protective gloves, safety shoes, etc., as necessary to ensure safety.

Precautions on Use

- Prevent foreign material, such as cutting chips or coolant, from entering the product. Failure to do so may cause damage.

- If the product is used in an environment where cutting chips, coolant, corrosive solvents, water, etc., may enter the product, use bellows, covers, etc., to prevent them from entering the product.

- Do not use the product at temperature of 80℃ or higher. Exposure to higher temperatures may cause the resin/rubber parts to deform/be damaged.

- If foreign material such as cutting chips adheres to the product, replenish the lubricant after cleaning the product.

- Slight rocking can inhibit the formation of a film of oil between the rolling surface and the area of contact, resulting in fretting. THK recommends periodically rotating the cross roller ring several times to help ensure that a film forms on the surfaces and rolling elements.

- Do not use undue force when fitting parts (pin, key, etc.) to the product. This may generate permanent deformation on the raceway, leading to loss of functionality.

- The matching mark of the inner or outer ring may be slightly misaligned when delivered. In that case, loosen the bolts that secure the inner or outer ring, and correct the alignment using a plastic hammer or the like, before installing it to the housing. (Let the securing rivets follow the housing.)

- When installing the Cross-Roller Ring, insert the ring by hammering the ring that is to be fixed (i.e. hammer the inner ring if the inner ring is to be fixed, or hammer the outer ring if the outer ring is to be fixed). Hammering the ring on the wrong side may cause damage.

- Insufficient rigidity or accuracy of mounting members causes the bearing load to concentrate on one point, and the bearing performance will drop significantly. Accordingly, give sufficient consideration to the rigidity/accuracy of the housing and base and strength of the fixing bolts.

- When installing or removing the Cross Roller Ring, do not apply force to the fixing rivets or the bolts.

- When mounting the presser flange, take into account the dimensional tolerances of the parts so that the flange firmly holds the inner and outer rings from the side.

Lubrication

- Do not mix different lubricants. Mixing greases using the same type of thickening agent may still cause adverse interaction between the two greases if they use different additives, etc.

- When using the product in locations exposed to constant vibrations or in special environments such as clean rooms, vacuum and low/high temperature, use the grease appropriate for the specification/environment.

- The consistency of grease changes according to the temperature. Take note that the torque of the Cross Roller Ring also changes as the consistency of grease changes.

- Since the Cross-Roller Ring unit contains high-quality lithium soap group grease No. 2, it can be used without initially adding grease. However, this product requires regular lubrication since it has a smaller internal space than ordinary roller bearings and because of the rolling contact structure of the rollers.

To replenish grease, it is necessary to access greasing holes that lead to the oil grooves formed on the inner and outer rings. As for the lubrication interval, normally replenish the same type of grease so that it is distributed throughout the interior at least every three to six months. Set the final lubrication interval/amount based on the actual machine.

When the bearing is filled up with grease, the initial rotational torque temporarily increases due to grease resistance. However, surplus grease will run off of the seals and the torque will return to the normal level in a short period. The thin type does not have an oil groove. Secure an oil groove in the inner diameter side of the housing for lubrication. - Excess grease may protrude from the outside edge of the cross-roller ring. The structure of peripheral components will require careful consideration if contamination due to grease around the edges of the device is a concern.

Storage

When storing the Cross Roller Ring, enclose it in a package designated by THK and store it in a room in a horizontal orientation while avoiding high temperature, low temperature and high humidity. After the product has been in storage for an extended period of time, lubricant inside may have deteriorated, so add new lubricant before use.

Disposal

Dispose of the product properly as industrial waste.

Precautions on Use

- The product does not have a greasing hole.

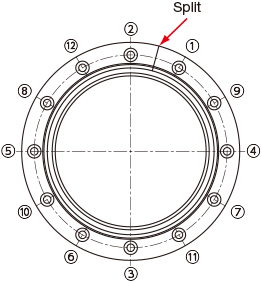

- The outer ring of this product was split to allow roller insertion. Pay attention to the mounting orientation so that the split section does not overlap with the area under the maximum load.

Fasten the bolts on the outer ring starting from the mounting holes to the right and left of the split section so that it will not open up.

Contact THK for details.

*This catalog only describes the product's basic specifications.

Please contact THK if you are considering purchasing this product.

Handling

- The improper installation of a spacer cage in a cross roller ring greatly impacts its rotational functionality. Please do not disassemble the cross roller ring.

- Take care not to drop or strike the cross roller ring. Otherwise, it may cause injury or damage the unit. Even if there is no outward indication of damage, a sudden impact could prevent the unit from functioning properly.

- Wear appropriate safety gear, such as protective gloves and safety shoes, when handling the product.

Precautions on Use

- Prevent foreign materials, such as cutting chips or coolant, from entering the product. Failure to do so could damage the product.

- Prevent foreign materials, such as cutting chips, coolant, corrosive solvents, or water from getting in the product by using a bellows or cover when the product is used in an environment where such a thing is likely.

- Do not use this product if the external temperature exceeds 80℃. If used above this temperature, there is a risk that the resin and rubber parts may deform or become damaged.

- Clean the product if foreign materials such as cutting chips adhere to the product.

- Slight oscillations can inhibit the formation of an oil film between the raceways and the area of contact for the balls, resulting in fretting. We recommend periodically rotating the cross roller ring several times to help ensure that a film forms on the surfaces and rolling elements.

- Please be aware that the cross roller ring seals are dust seals and may be unable to prevent the ingress of very fine particles and liquids.

- Do not forcibly drive a pin, key, or any other positioning device into the product. This could create indentations on the raceways and impair the product's function.

- When installing the cross roller ring to a housing, if the inner ring is fixed, hammer the inner ring to insert it. If the outer ring is fixed, hammer the outer ring. Hammering the non-fixed side may cause damage to the unit.

- If the mounting material lacks sufficient rigidity or accuracy, the bearing load may be focused in one area, and bearing functionality will dramatically decrease. Therefore, carefully consider the rigidity and accuracy of the housing and base, and the strength of the securing bolts.

- Be careful of the dimensional tolerances of the mounting components to ensure that the presser flange firmly holds the inner and outer rings from the sides. (Straight-type inner ring)

Lubrication

- Do not mix different lubricants. Even grease containing the same type of thickening agent may, if mixed, interact negatively due to disparate additives or other ingredients.

- When using the product in locations exposed to constant vibrations or in special environments such as in clean rooms, vacuums, and low/high temperatures, use a lubricant suitable for its use/environment.

- Grease viscosity can vary depending on the temperature. Please keep in mind that the torque of the cross roller ring may be affected by changes in viscosity.

- Excess grease may protrude from the outside edge of the cross-roller ring. The structure of peripheral components will require careful consideration if contamination due to grease around the edges of the device is a concern.

- When planning to use a special grease or a lubricant other than grease, please contact THK.

Storage

When storing the cross roller ring, pack it as designated by THK and store it indoors in a horizontal position away from high or low temperatures and high humidity.

Please note that after the product has been in storage for an extended period, the lubricant inside may have deteriorated.

Disposal

The product should be treated as industrial waste and disposed of appropriately.