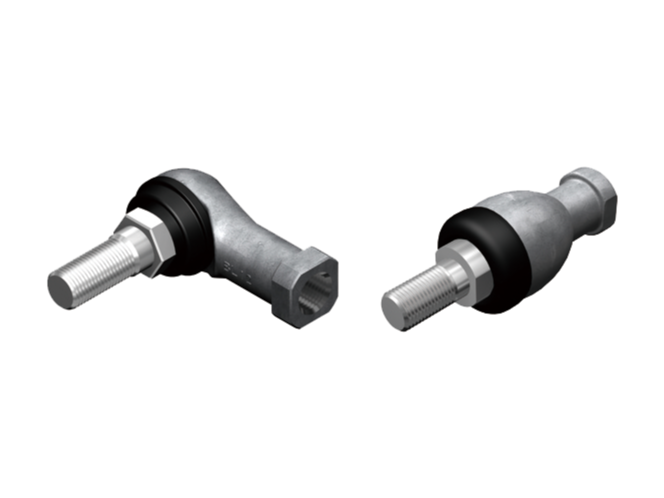

With the link ball, a highly accurate bearing steel ball used in the spherical area is first encased in the holder by die cast molding and then is specially welded with the shank. This unique process enables the mirror surface of the steel ball to be transferred or duplicated on the spherical surface inside the holder to ensure full contact between the ball and the holder. As a result, smooth motion is achieved with the smallest possible clearance.