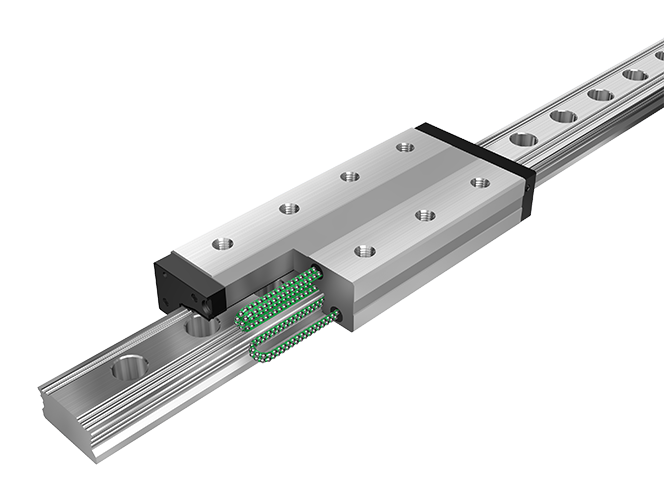

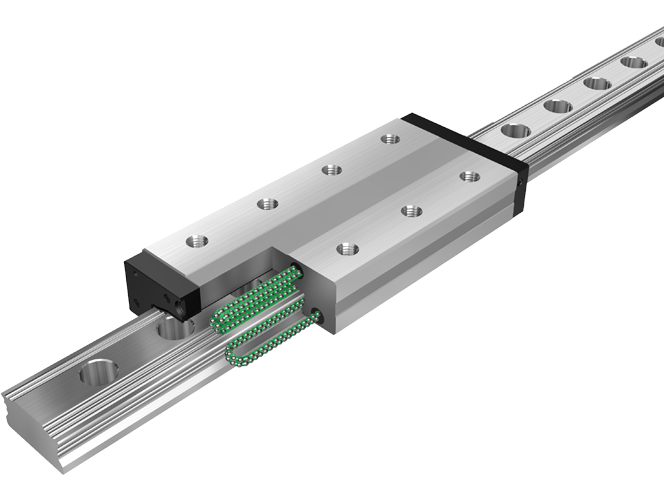

Caged Ball LM Guide Super-Low Waving Model SPS

Model SPS achieves super-low waving comparable to hydrostatic guides. In addition, the deformation of the ball is minimized to achieve ultra-high rigidity that surpasses even roller guides.

Size : 15,20,25,30,35,45

Types

Highlight feature tags

- Ultra long block

- Bolts mounted from above

- Ultra long block

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 15.9 to 126 / Basic static load rating 41.2 307

Size :

15,20,25,30,35,45

Features

We achieve ultra-low waving and high rigidity through our unique technology.

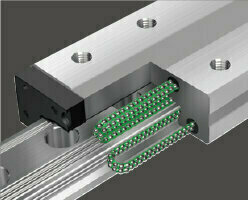

Eight raceway grooves

Doubling the number of grooves halves the load on the balls and enables ultra-low waving on a nanoscopic scale.

Small-diameter balls

The increased number of loadbearing balls stabilizes support and reduces compression when under a load.

Ultra-long blocks

More balls can be incorporated, reducing each ball's individual load.Demonstrates ultra-low waving and ultra-high rigidity.

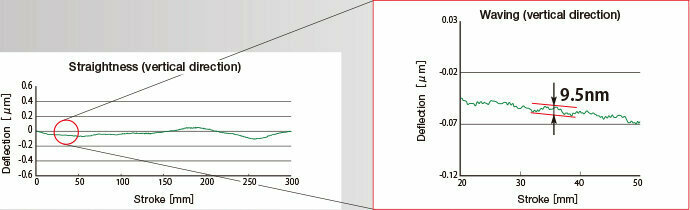

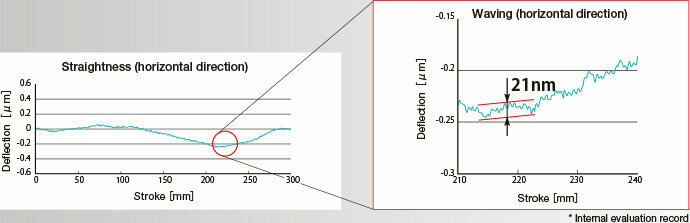

Ultra-low waving

Ultra-low waving performance that breaks conventional standards.

Proficient in nanometer stroke applications.

Waving Evaluation

The product was installed on a single-axis table, and the vertical and horizontal displacement during operation was measured. SPR/SPS models have 1/10 the waving value compared to our conventional, standard LM Guide models (100 nm-300 nm).

| Tested model | SPS25LR |

|---|---|

| Rail span | 250mm |

| Block span | 250mm |

| Measurement point | Upper 250 mm of the middle of the table |

| Measurement direction | Vertical and horizontal |

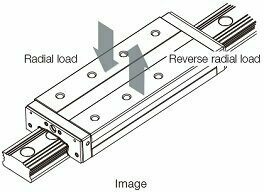

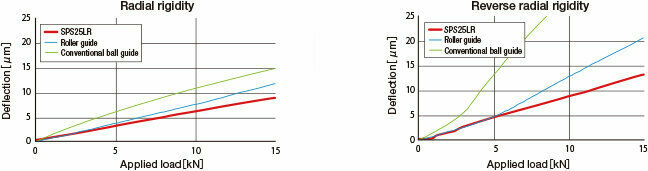

Ultra-high Rigidity

Achieves overwhelming rigidity with small-diameter balls and ultra-long blocks.

Improves the precision of load-bearing strokes and provides stable motion.

Rigidity Comparison and Evaluation

A force was applied to the product from above or below, and the resulting displacement was measured. It achieves even higher rigidity than a roller guide.

* This test was intended to compare the clearance C1.

Lineup

|

Each Model |

Model No. |

||||||

| 15 | 20 | 25 | 30 | 35 | 45 | ||

| SPS | ○ | ○ | ○ | ○ | ○ | ○ | |

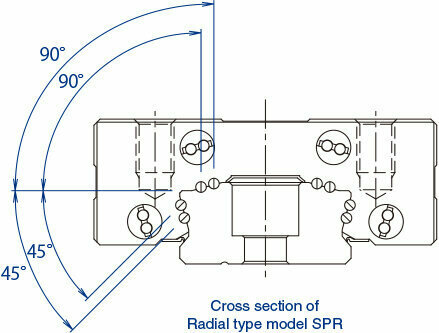

Positions each ball at a contact angle of 45° and bears load from all directions.

Can be used in various positions such as horizontally and upside down.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Lengths and Maximum Lengths of LM Rails

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |