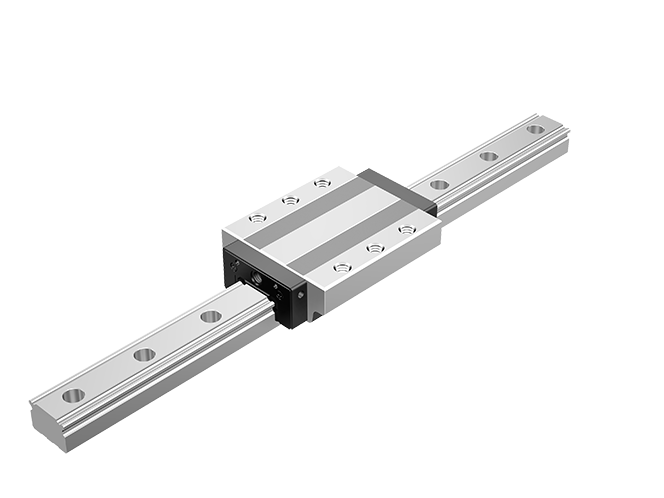

Full-Ball LM Guide Super-Heavy Load (Radial) Models NR-X / NR for Machine Tools

These are LM Guide models for super-heavy loads. The raceways are cut into deep grooves that have a radius closer to that of the balls than in the conventional design. They also have high rigidity, vibration and shock resistance, and damping characteristics, which are required for machine tools. As a result, they are optimal for receiving radial loads in particular.

Size : 25,30,35,45,55,65,75,85,100

Types

Highlight feature tags

- Flange

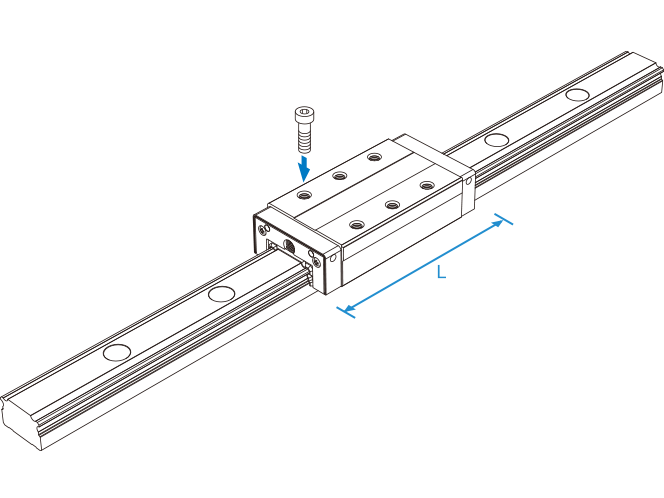

- Long block LM Guide

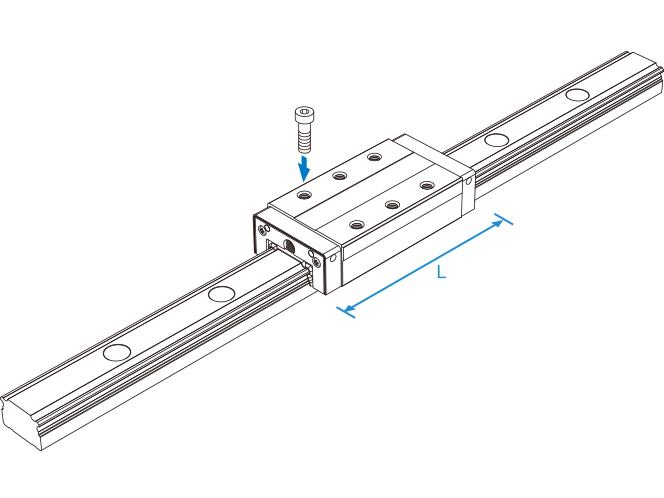

- Ultra long block

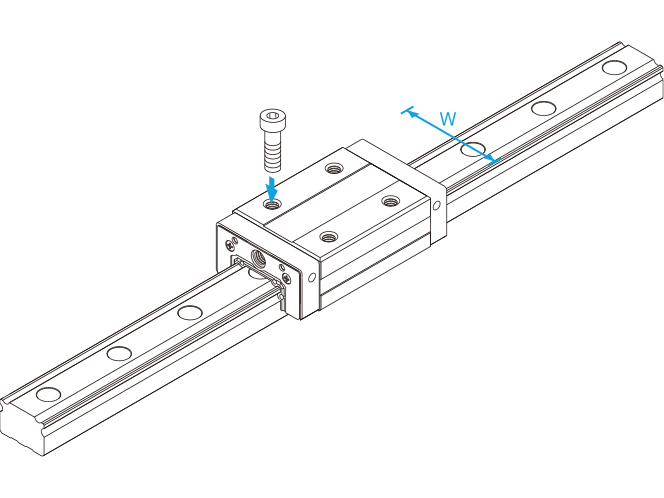

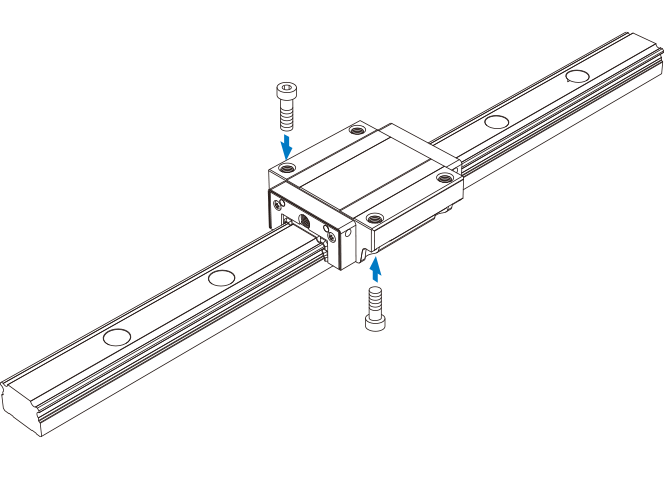

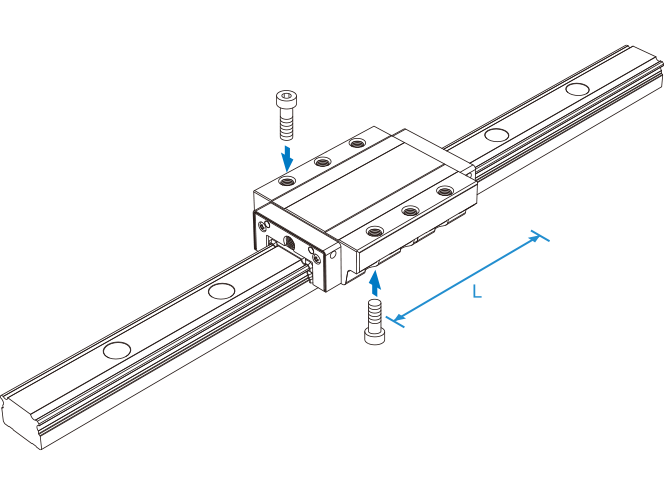

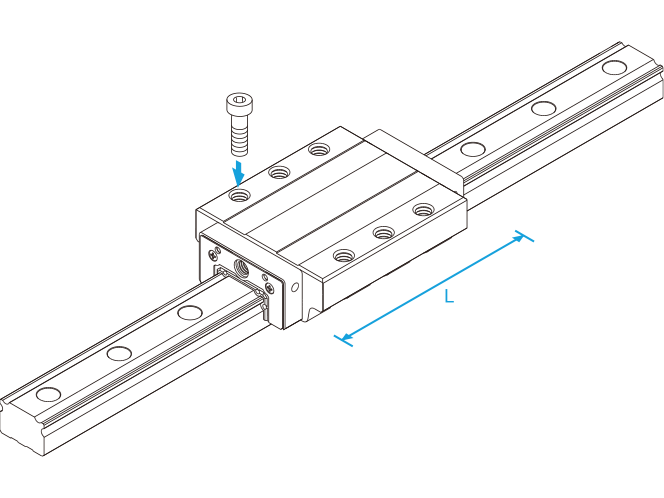

- Bolts mounted from above and below

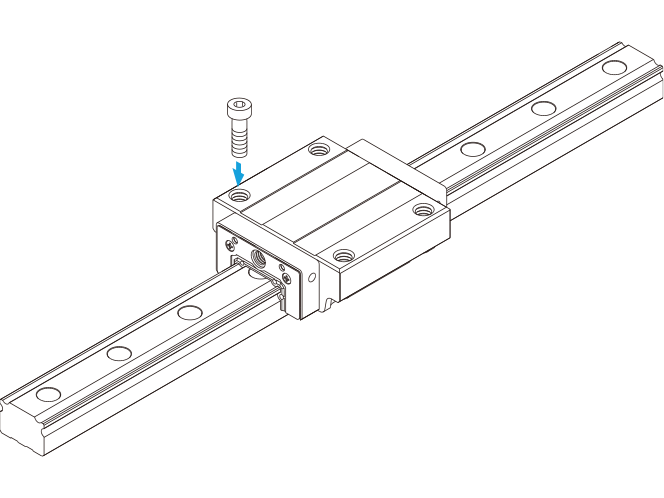

- Bolts mounted from above

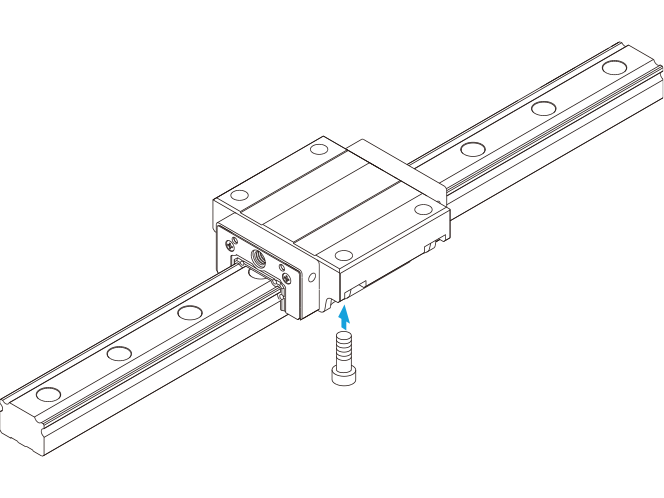

- Bolts mounted from below

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 37.1 to 479 / Basic static load rating 68.1 to 1040

Size :

25,30,35,45,55,65,75,85,100

- Long block LM Guide

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 45.4 to 599 / Basic static load rating 800 to 1300

Size :

25,30,35,45,55,65,75,85,100

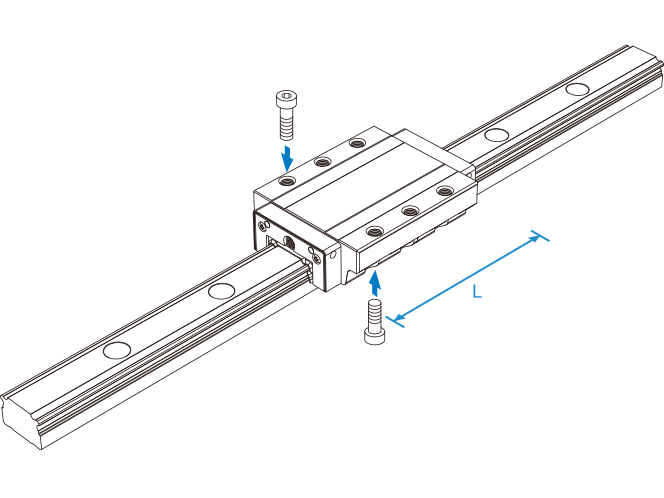

- Ultra long block

- Bolts mounted from above

Basic load rating(kN) : Basic dynamic load rating 71.0~423.1 / Basic static load rating 172.6~967.1

Size :

25,30,35,45,55,65

- Flange

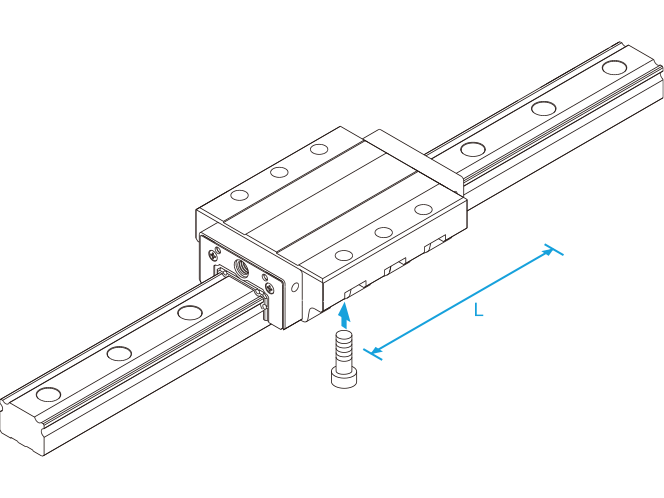

- Bolts mounted from above and below

Basic load rating (kN): Basic dynamic load rating 37.1 to 208.7 / Basic static load rating 68.1 to 351.7

Size :

25,30,35,45,55,65

- Flange

- Long block LM Guide

- Bolts mounted from above and below

Basic load rating (kN): Basic dynamic load rating 45.4 to 268.9 / Basic static load rating 90.to 505.5

Size :

25,30,35,45,55,65

- Flange

- Ultra long block

- Bolts mounted from above and below

Basic load rating(kN) : Basic dynamic load rating 71.0~423.1 / Basic static load rating 172.6~967.1

Size :

25,30,35,45,55,65

- Flange

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 271 to 479 / Basic static load rating 610 to 1040

Size :

75,85,100

- Flange

- Long block LM Guide

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 355 to 599 / Basic static load rating 800 to 1300

Size :

75,85,100

- Flange

- Bolts mounted from below

Basic load rating (kN): Basic dynamic load rating 271 to 479 / Basic static load rating 610 to 1040

Size :

75,85,100

- Flange

- Long block LM Guide

- Bolts mounted from below

Basic load rating (kN): Basic dynamic load rating 355 to 599 / Basic static load rating 800 to 1300

Size :

75,85,100

Features

Structure and Features

Balls roll in four rows of raceways precision-ground on an LM rail and an LM block, and endplates incorporated in the LM block allow the balls to circulate. The raceways are cut into deep grooves that have a radius closer to that of the balls than in the conventional design, using special equipment and an extremely precise cutting technique. This design allows high rigidity, high vibration/impact resistance and high damping capacity, all of which are required for machine tools, thus making these models capable of bearing ultra-heavy loads.

The excessively large differential slip occurring in a Gothic-arch groove does not happen with these models. They smoothly travel and achieve high positioning accuracy during fast feeding. During the cutting operation, appropriate slip occurs according to the cutting load, the rolling resistance is increased and the damping capacity is increased. Thus, models NR and NRS are highly rational LM Guides.

Improved Damping Capacity

While the machine tool (equipped with NR or NRS) is not cutting a workpiece during operation, the LM Guide travels normally and smoothly. While the machine tool is cutting the workpiece, the cutting force is applied to the LM Guide to increase and the contact area between the balls and the raceway, allowing an appropriate mixture of rolling and sliding motions to be achieved. Accordingly, the friction resistance is increased and the damping capacity is improved. Since the absolute slip during the rolling and sliding motion is insignificant, it causes little wear and does not affect the service life.

Highly Rational LM Guide

The excessively large differential slip occurring in a Gothic-arch groove does not happen with these models. They smoothly travel and achieve high positioning accuracy during fast feeding. During the cutting operation, appropriate slip occurs according to the cutting load, the rolling resistance is increased and the damping capacity is increased. Thus, models NR and NRS are highly rational LM Guides.

High Rigidity

To increase the rigidity of the LM block and the LM rail, which may deteriorate the overall rigidity of the LM Guide in the reverse radial and lateral directions, THK made full use of FEM to achieve optimal design within the limited dimensional range. THK offers two identically sized models with different characteristics, namely the Radial Type Model NR-X and 4 way Type Model NRS-X. Users can select the model that best suits their specifications.

Ultra-heavy Load

Since the curvature of the raceway is approximated to the ball diameter, the ball contact area under a load is increased and the LM Guide is capable of receiving an ultra-heavy load.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Lengths and Maximum Lengths of LM Rails

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |