LM Guide Models for Special Environments

We have created a series of LM Guide models that are suited to use in special environments with high temperature or requiring high corrosion resistance.

Types

Highlight feature tags

- High accuracy

- Lightweight

- Self-adjusting capability

- 4-way equal load

- Radial

- Miniature

- High temperature

- High corrosion resistance

- Medium-to-low vacuum

- Low permeability

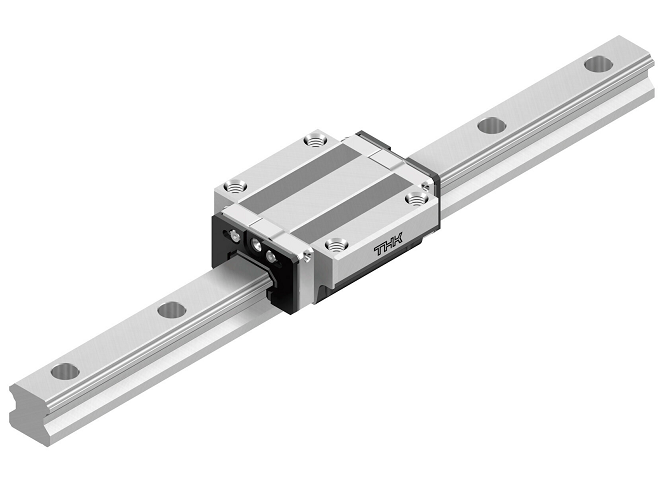

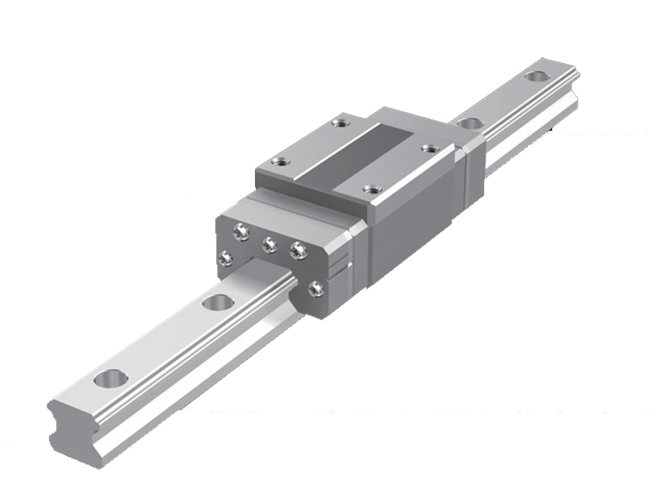

High-Temperature Model HSR-M1

- High accuracy

- Self-adjusting capability

- 4-way equal load

- High temperature

Size : 15,20,25,30,35

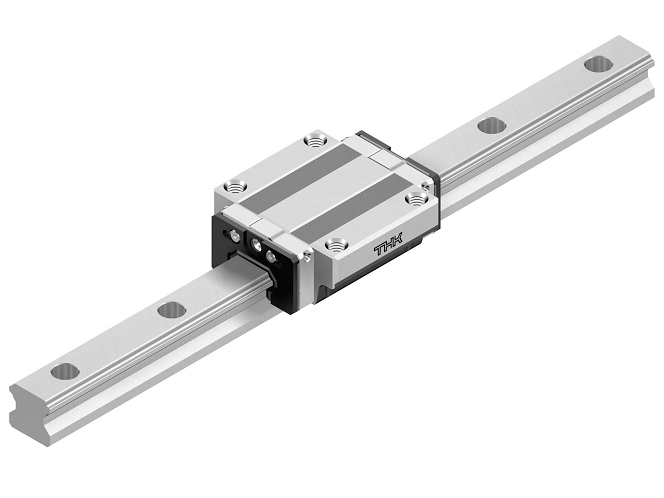

High-Temperature Model SR-M1

- High accuracy

- Self-adjusting capability

- Radial

- High temperature

Size : 15,20,25,30,35

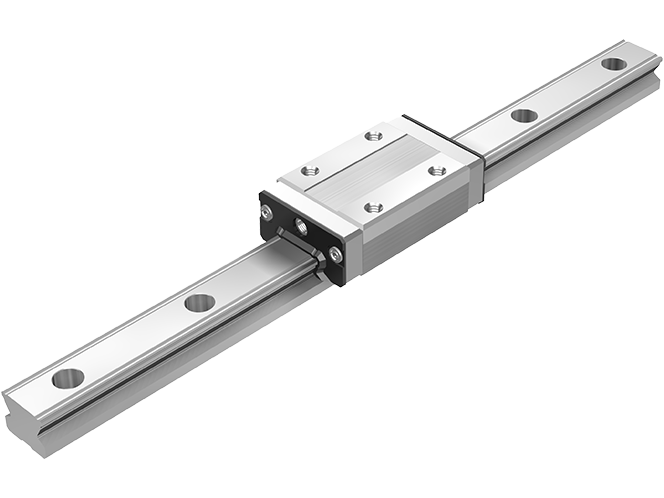

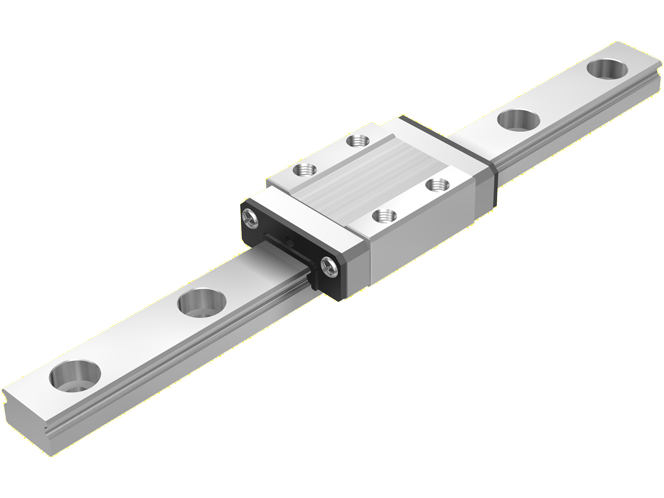

High-Temperature Model RSX-M1

- High accuracy

- 4-way equal load

- Miniature

- High temperature

Size : 9,12,15

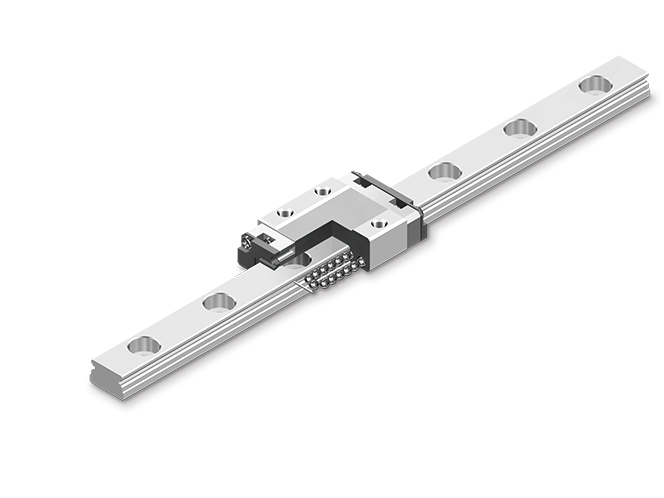

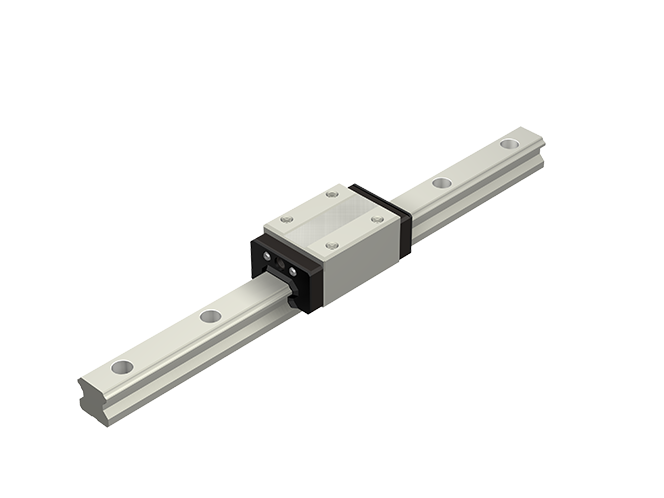

High-Temperature Model RSR-M1

- High accuracy

- Lightweight

- 4-way equal load

- Miniature

- High temperature

Size : 9,12,15,20

Corrosion-Resistant Model HSR-M2

- High accuracy

- Self-adjusting capability

- 4-way equal load

- High corrosion resistance

Size : 15,20,25

Low-Magnetic Permeability Model HSR-M3

- High accuracy

- Low permeability

- 4-way equal load

Size : 15,20,25

Medium-to-Low Vacuum Model HSR-M1VV

- High accuracy

- 4-way equal load

- Medium-to-low vacuum

Size : 15

Features

High-Temperature LM Guide

- The use of stainless steel in the endplates and high-temperature rubber in the end seals enables a maximum service temperature of 150°C.

- Since it is dimensionally stabilized, the product demonstrates superb dimensional stability after being heated or cooled (note that it shows linear expansion at high temperature).

- Since the LM block, LM rail, and balls use stainless steel, which is highly corrosionresistant,this product is optimal for clean room applications.

- This product uses high-temperature grease that shows little grease-based fluctuation in rolling resistance even if the temperature changes from normal to high levels.

LM Guide for Medium-to-Low Vacuums

- This LM Guide can be used in various environments ranging from atmospheric pressure to a vacuum (10-3[pa]).

- This product is capable of withstanding baking temperatures up to 200°C*.

* If the baking temperature exceeds 100°C, multiply the basic load rating by the temperature coefficient. - The use of a labyrinth end seal designed for medium-to-low vacuum increases grease retention and allows extended use in a vacuum.

- The use of a grease designed for medium-to-low vacuums enables stable rolling resistance.

Corrosion-Resistant LM Guide

- The LM rail uses the highly corrosion-resistant, austenitic stainless steel SUS304, and the LM block and balls are made of SUS431, the martensitic stainless steel with the highest corrosion resistance. This enables a drastic increase in corrosion resistance over conventional stainless steel (SUS440C).

Corrosion Resistance Comparison