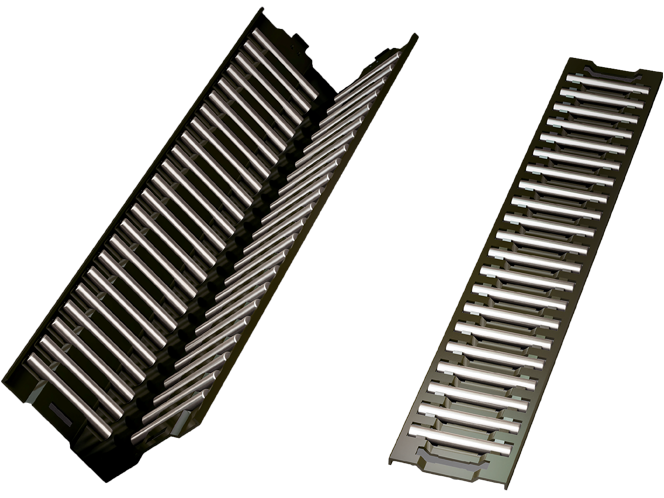

Flat Roller

For the flat roller, a precision roller compliant with JISB 1506 is installed in the pocket of the cage whose weight is reduced and rigidity is improved by press forming a steel plate into an M shape. The roller has a structure retained in the cage pocket so as to not drop off. This flat roller is used between the two raceways, so it moves in the same direction as that of the table by only half of the amount the table moves. For example, if the table moves by 500 mm, the flat roller moves by 250 mm in the same direction.

The flat roller is ideal for large machine tools such as planers, horizontal milling machines, and cylindrical grinding machines, in addition to locations requiring high accuracy such as surface grinding machines, cylindrical grinders, and optic measuring machines.

Types

Highlight feature tags

- Lightweight

- Load capacity

- Lightweight

- Load capacity

- Lightweight

- Load capacity

Features

Structure and Features

For the Flat Roller, precision rollers compliant with JIS B1506 are installed in a thin, steel plate cage, which is formed into an "M" shape for improved rigidity and light weight. The pockets of the cage are designed to prevent the rollers from falling out. The Flat Roller is sandwiched between two raceways, so it moves half the distance traveled by the table. For example, if the table moves 500 mm, the Flat Roller moves 250 mm in the same direction. The Flat Roller is optimal for large machine tools such as planer, horizontal milling machines and cylindrical grinding machines, and for locations requiring high accuracy such as surface grinding machines, cylindrical grinder and optic measuring machines.

Large Load Capacity

Sine rollers are installed in short pitches, the Flat Roller has a large load capacity, and depending on the conditions, it can be used on the raceway of a mold that is little hardened. In addition, the deflection rigidity of the table is almost the same as that of a sliding surface.

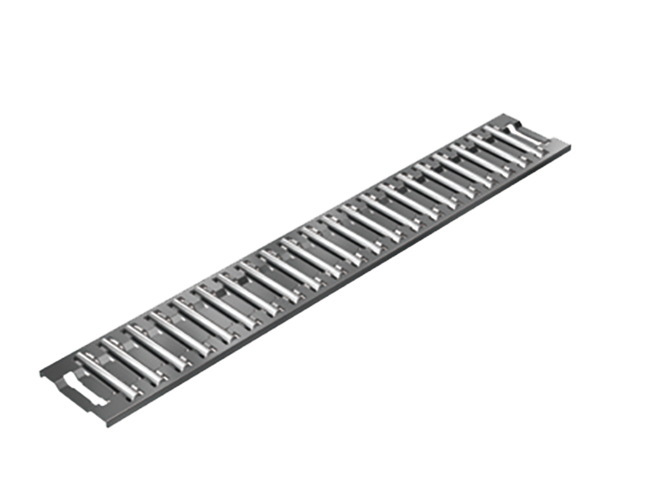

Combined Accuracy of 90° V Surface and Flat Surface Supported as Standard

The Flat Roller is designed so that it can be mounted on the 90° V-flat sliding surface, which is the most common configuration among narrow guide types of tables and saddles of machinery. It allows the product to be used without major design change.

Lowest Friction among Roller Type LM Systems

Since the rollers are evenly held in a light, rigid cage, friction between rollers is eliminated and skewing of the rollers is minimized. As a result, a small friction coefficient (μ= 0.001 to 0.0025) is achieved, and stick-slip, which is problematic with sliding surfaces, does not occur.

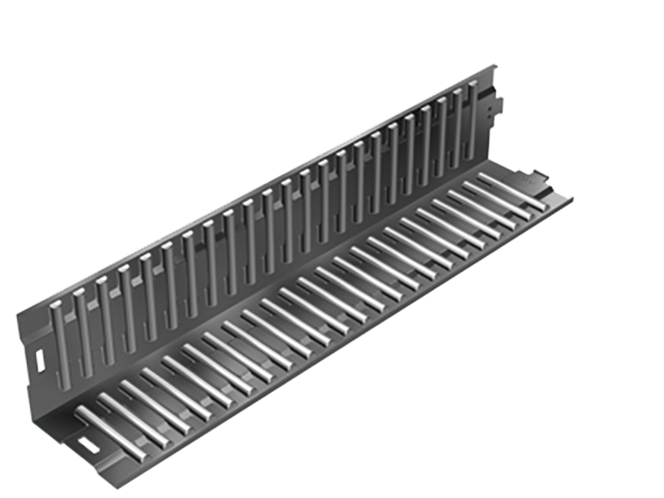

Instant Connection of the Cage

When installing the Flat Roller in a large machine, it can easily be connected on the bed. This allows the Flat Roller to be installed even with the longest type.